Laser cutting device

A laser cutting and cutting head technology, which is applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems such as the inability to apply the cutting of new gel lithium-ion battery pole pieces, and the destruction of gel electrolytes by small particles. Achieve the effect of preventing burning, reducing failure rate, and reducing curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

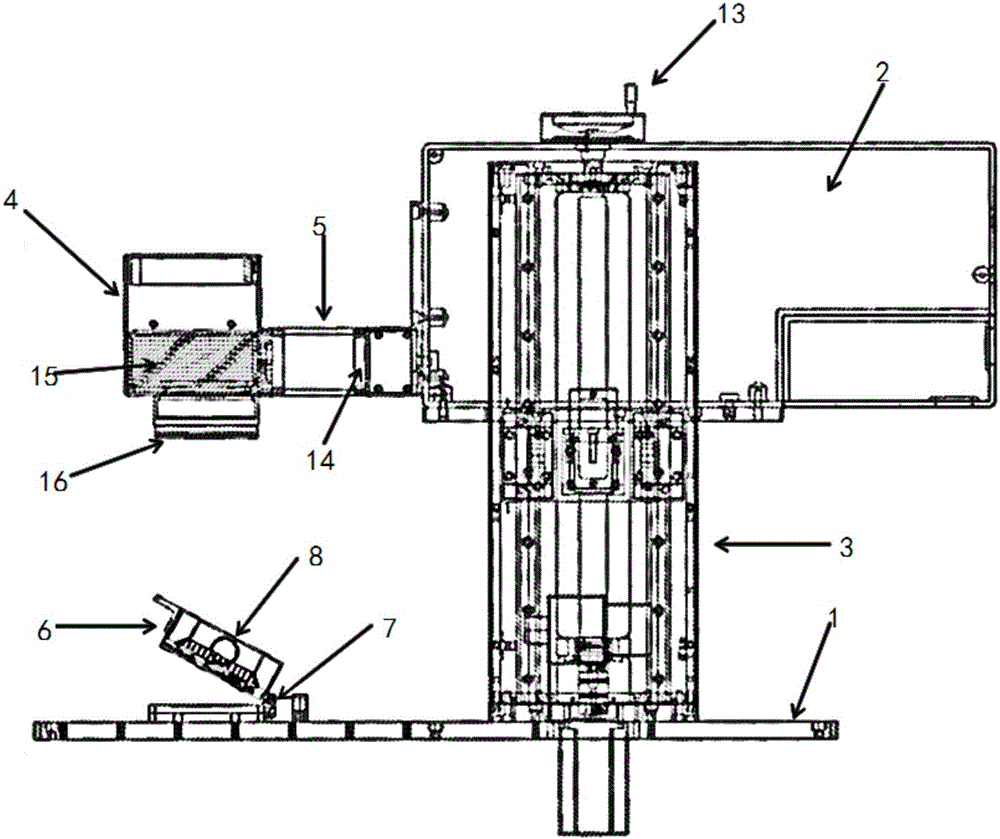

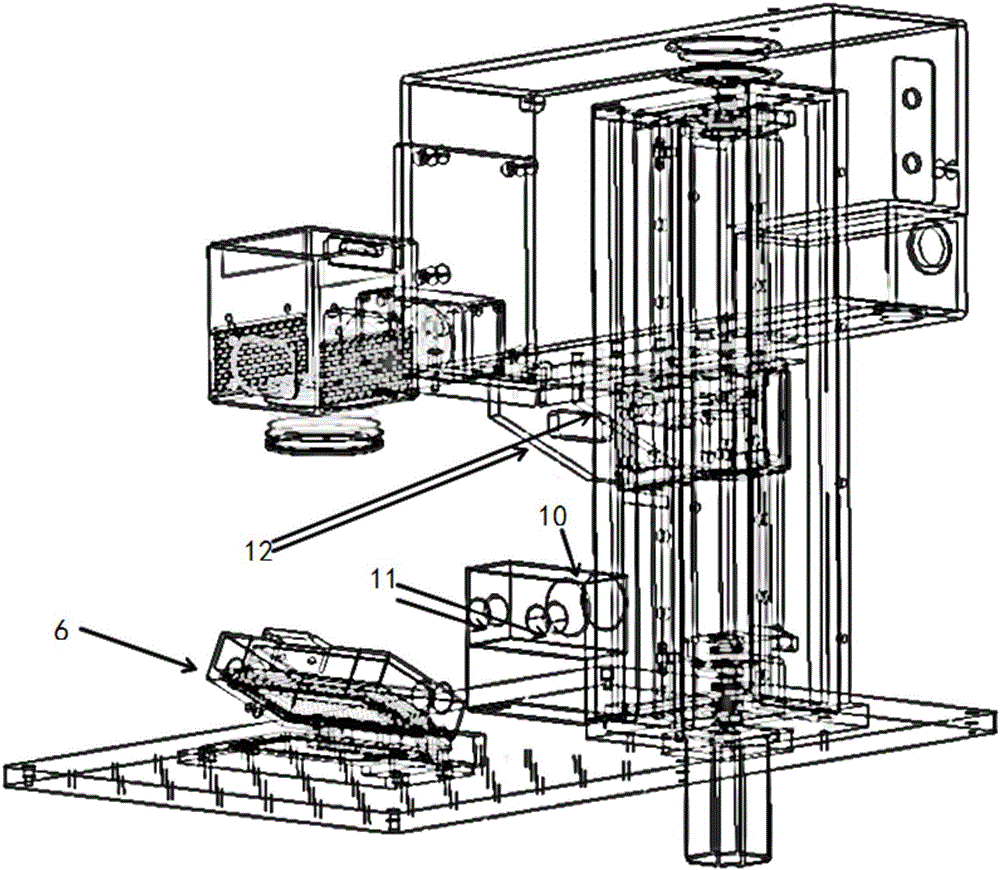

[0030] The embodiment of the present application provides a laser cutting device, which solves the technical problem that the laser cutting device in the prior art will produce small particles that destroy the gel electrolyte, making it unsuitable for cutting the pole pieces of the new gel lithium-ion battery. Provided is a laser cutting device that can be applied to cutting pole pieces of a novel gel lithium-ion battery.

[0031] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

[0032] The application provides a laser cutting device, the device comprising:

[0033] floor;

[0034] The host of the laser transmitter, the host is movably connected to the base plate, and can move up and down relative to the base plate; the host is connected to the cutting head through a support arm;

[0035] pole piece clamp, the pole piece clamp is movably connected to the base, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com