Machine tool plane contour error monocular measuring method

A measuring method and technology of plane profile, which can be used in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc., and can solve problems such as limited measurement field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

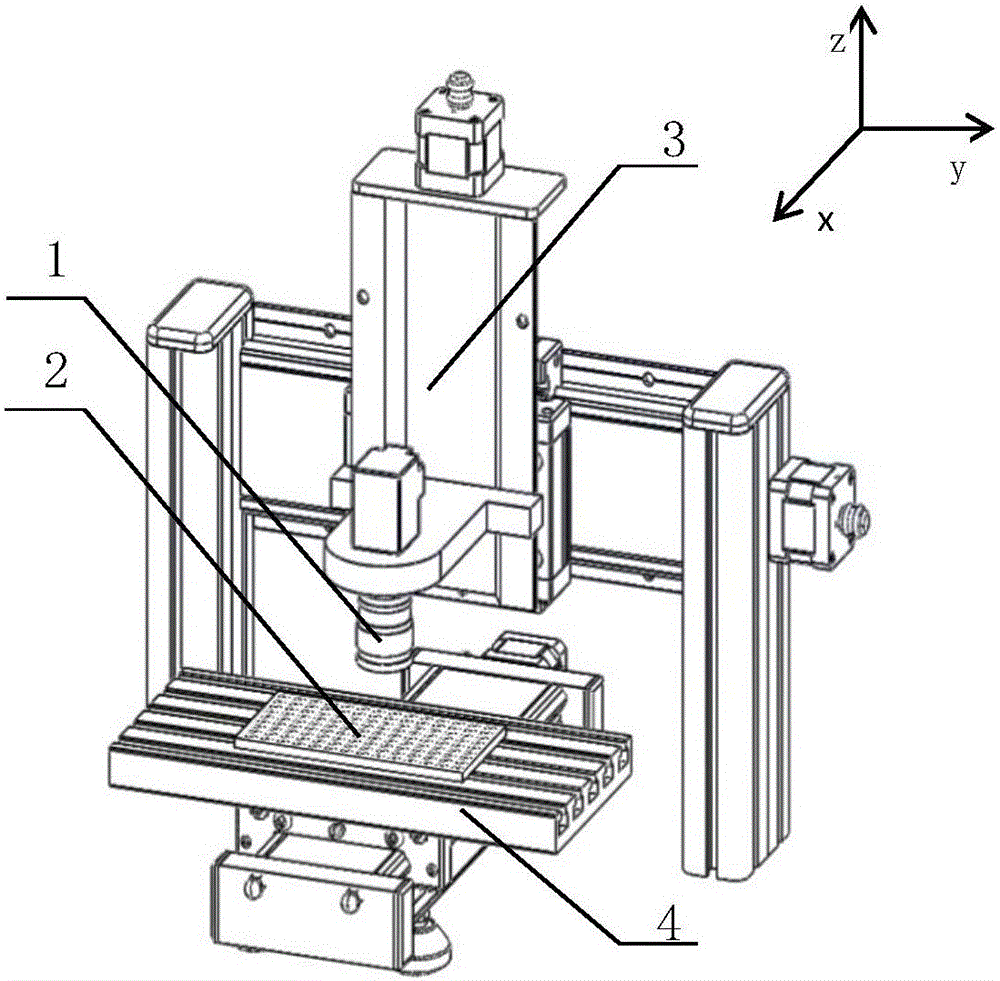

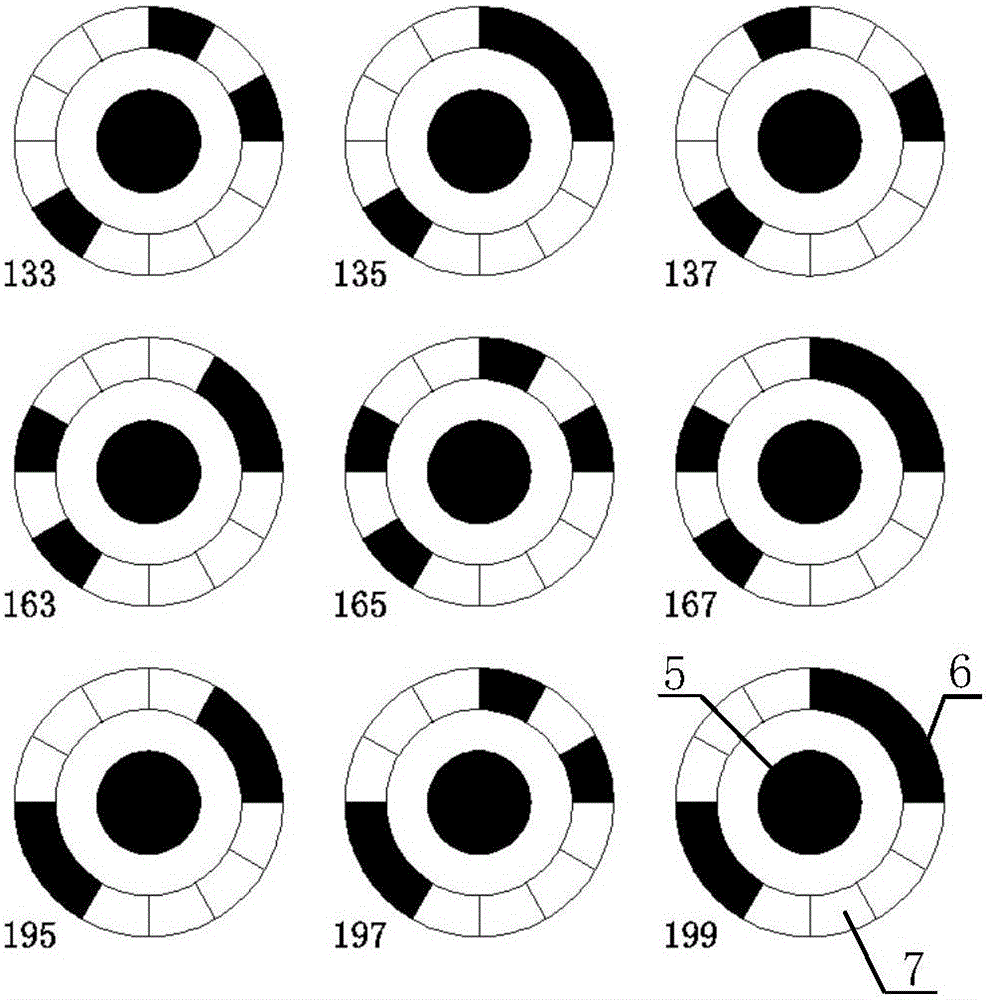

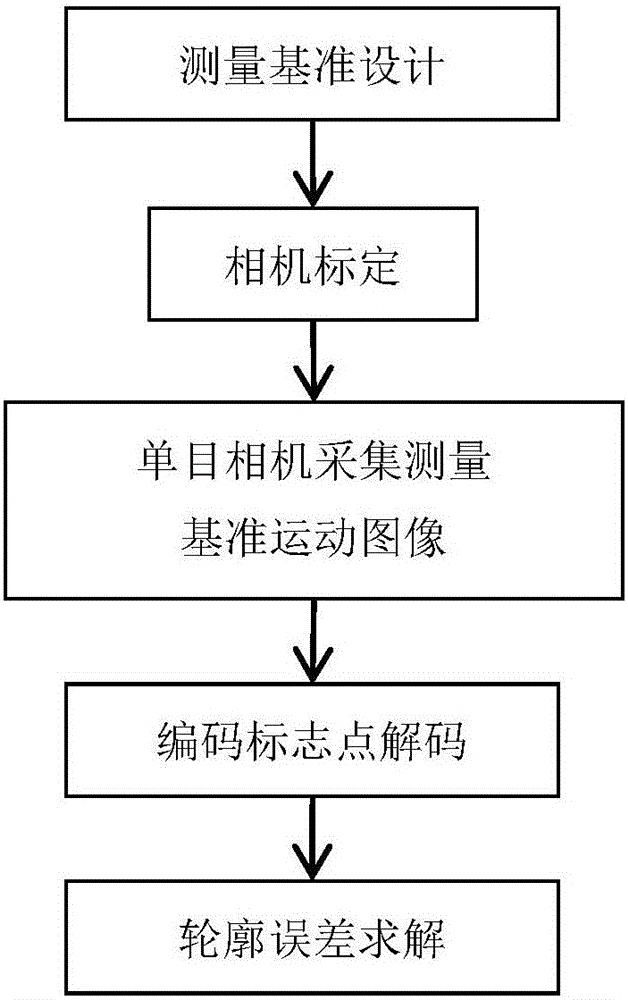

[0035] attached figure 1 is the plane profile error measurement system of the machine tool, in which 1 is a monocular camera, 2 is the measurement reference, 3 is the machine column, and 4 is the plane of the machine table. The present invention firstly designs the measurement reference 2 of the matrix-arranged ring-coded mark points, fixes it on the plane 4 of the machine tool workbench, and drives the measurement reference 2 to move through the X-axis and Y-axis linkage of the machine tool, and the monocular camera 1 is installed perpendicular to the machine tool plane. On the column 3 of the machine tool, after calibration, the sequence image of the measurement reference 2 is collected, and several coded mark points at the center of the image are identified, positioned and solved for the actual motion trajectory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com