Rope Drive Decoupling Mechanism Based on Gear Train and Its Decoupling Method

A technology of rope drive and wheel train, which is applied in the field of manipulator system, can solve the problems that the control accuracy and dynamic response characteristics of the manipulator are difficult to guarantee, the complexity of the control algorithm increases, and the friction between the rope and the lasso is large, so as to simplify the motion control algorithm , Simple structure, avoiding the effect of large friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

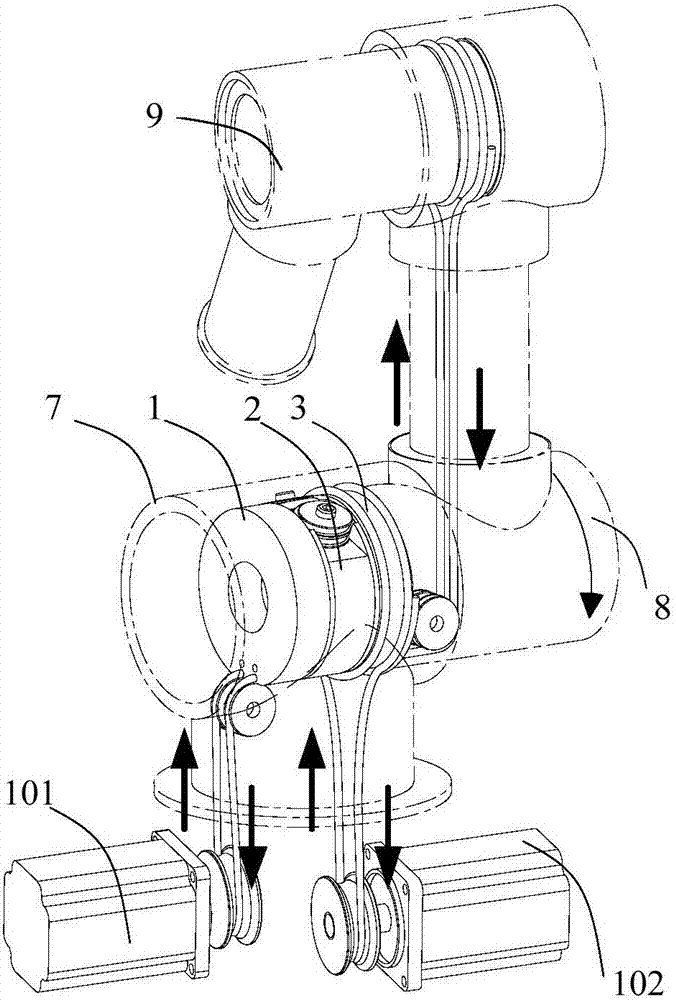

[0032] The accompanying drawings disclose non-restrictive structural schematic diagrams of the present invention involved and preferred implementations, and the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

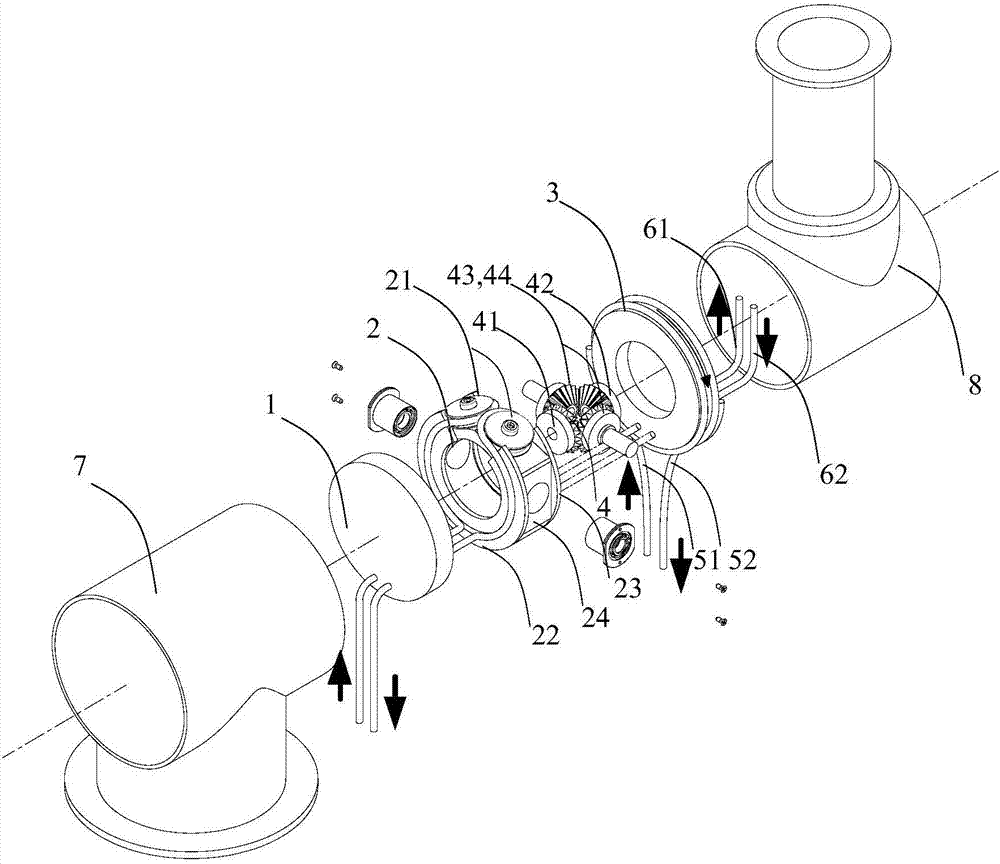

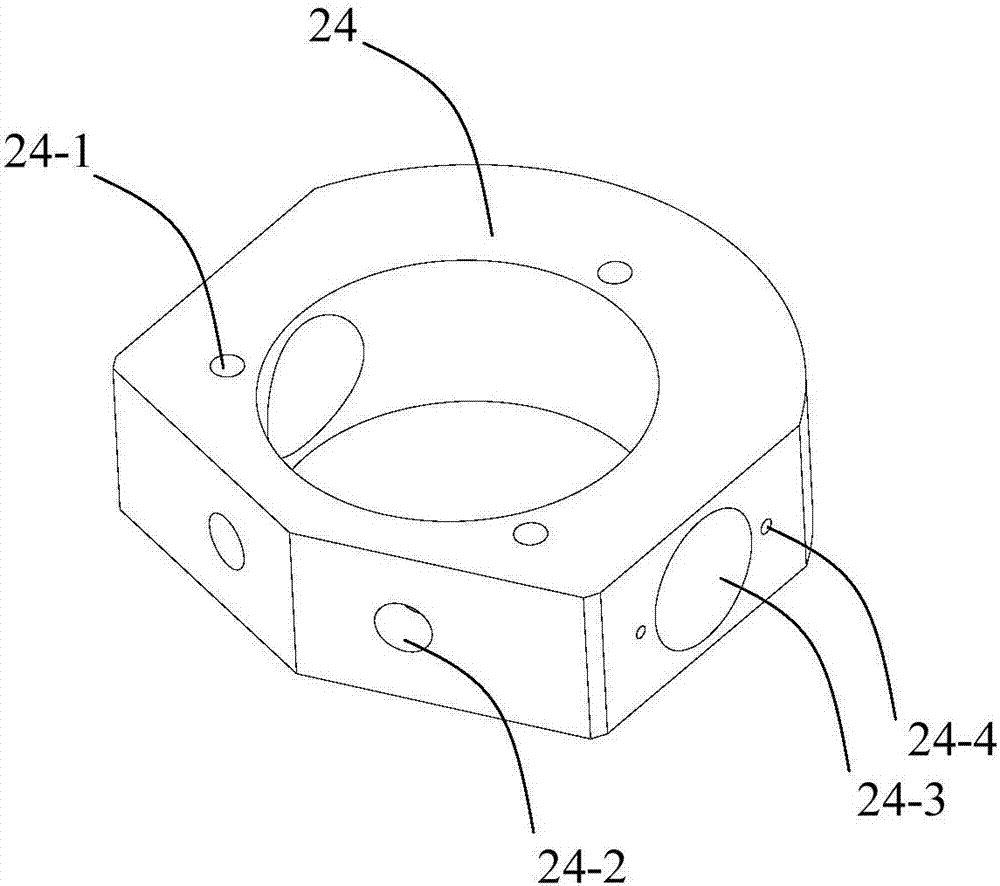

[0033] see figure 1 and image 3 As shown, the present invention discloses a passive decoupling mechanism for the driving rope movement of a rope-driven series mechanical arm, which sequentially includes a joint base 7, a fixed wheel 1, a follower wheel 2, a planetary gear train 4, a driving wheel 3, The current joint connecting rod 8; wherein the fixed wheel 1 is fixedly connected with the joint base 7 and cannot rotate; the driving wheel 3 is fixedly connected with the current joint connecting rod 8, and rotates following the current joint connecting rod 8; the fixed gear 41 is connected to the fixed wheel 1 through a flat key Connected, the driving gear 42 is connected with the driving whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com