Automatic splicing device of wood boards

A wood plank and automatic technology, which is applied in the field of wood plank automatic splicing device, can solve the problems of wood plank pressure, long bonding time, reduced work efficiency, and large land occupation, so as to achieve easy placement of wood, increase work efficiency, and reduce land occupation. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

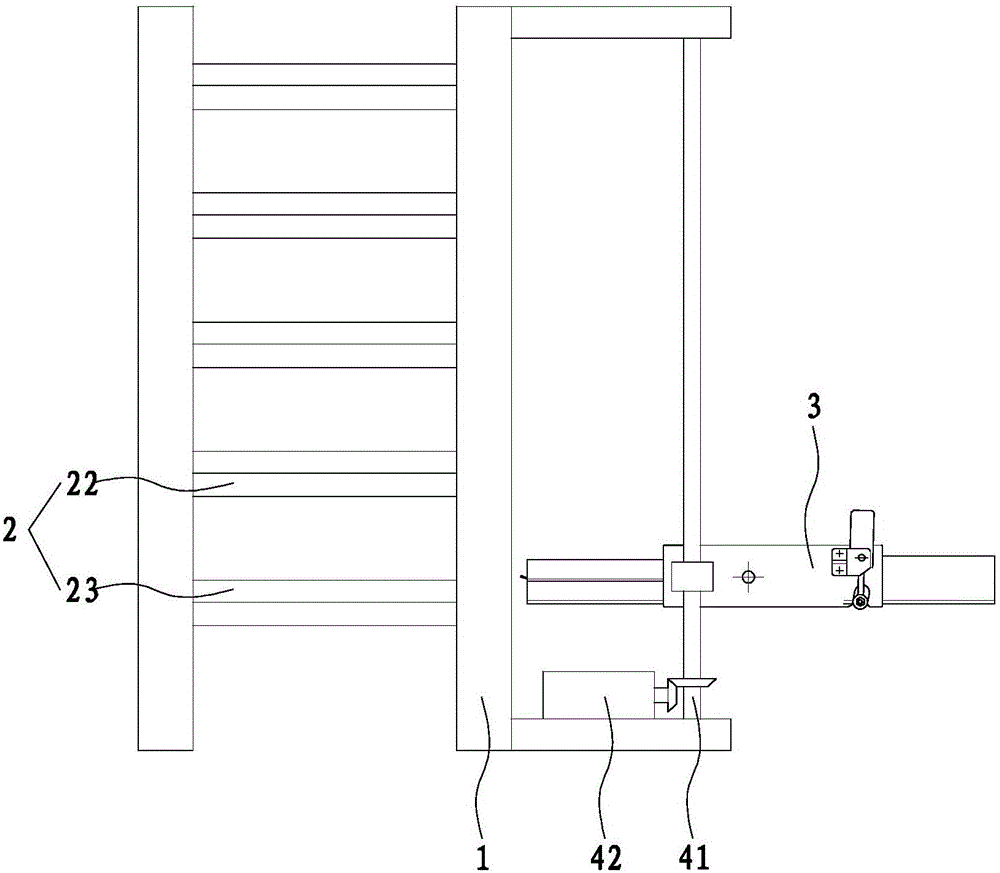

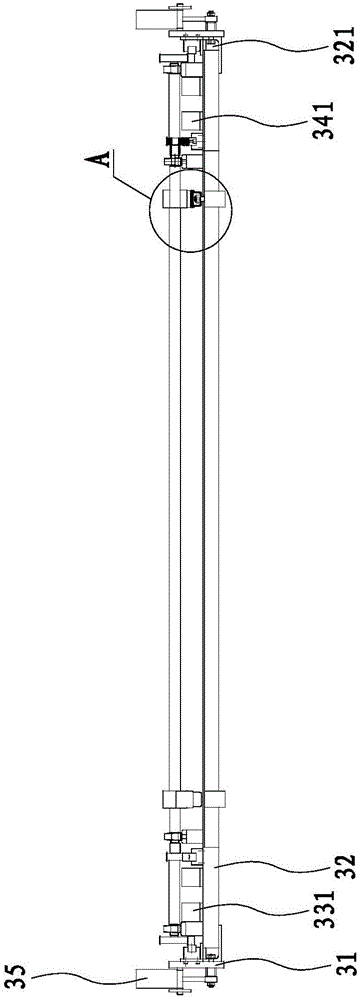

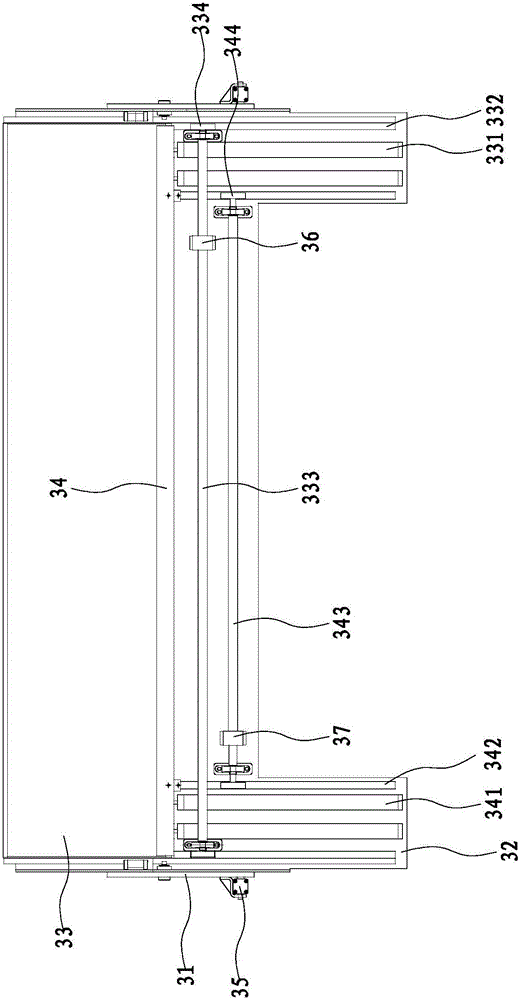

[0024] refer to Figure 1 to Figure 8 , the present embodiment provides a kind of plank automatic assembling device, comprises frame 1, a plurality of pressurizing devices 2 arranged on frame 1, feeding device 3 for conveying planks to pressurizing device 2, set on frame 1 The lifting device 4 connected with the feeding device 3 and the electrical control system, the lifting device 5 includes a screw 41 rotatably arranged on the left and right sides of the frame 1, a servo motor 42 that drives the screw 41 to rotate, and the feeding Device 3 comprises feeding frame 31, is located on the supporting material frame 32 on the feeding frame 31, tray 33, is located at the push cylinder 331 on the material supporting frame 32, is located at the position limiting cylinder 341 on the material supporting frame 32, described supporting The material rack 32 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com