A device and method for 3D printing architectural decoration

An architectural decoration and 3D printing technology, applied in the field of additive manufacturing, can solve the problems of difficult components, low precision, and high manufacturing costs, and achieve the effect of improving precision and quality, high precision, and small dimensional errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

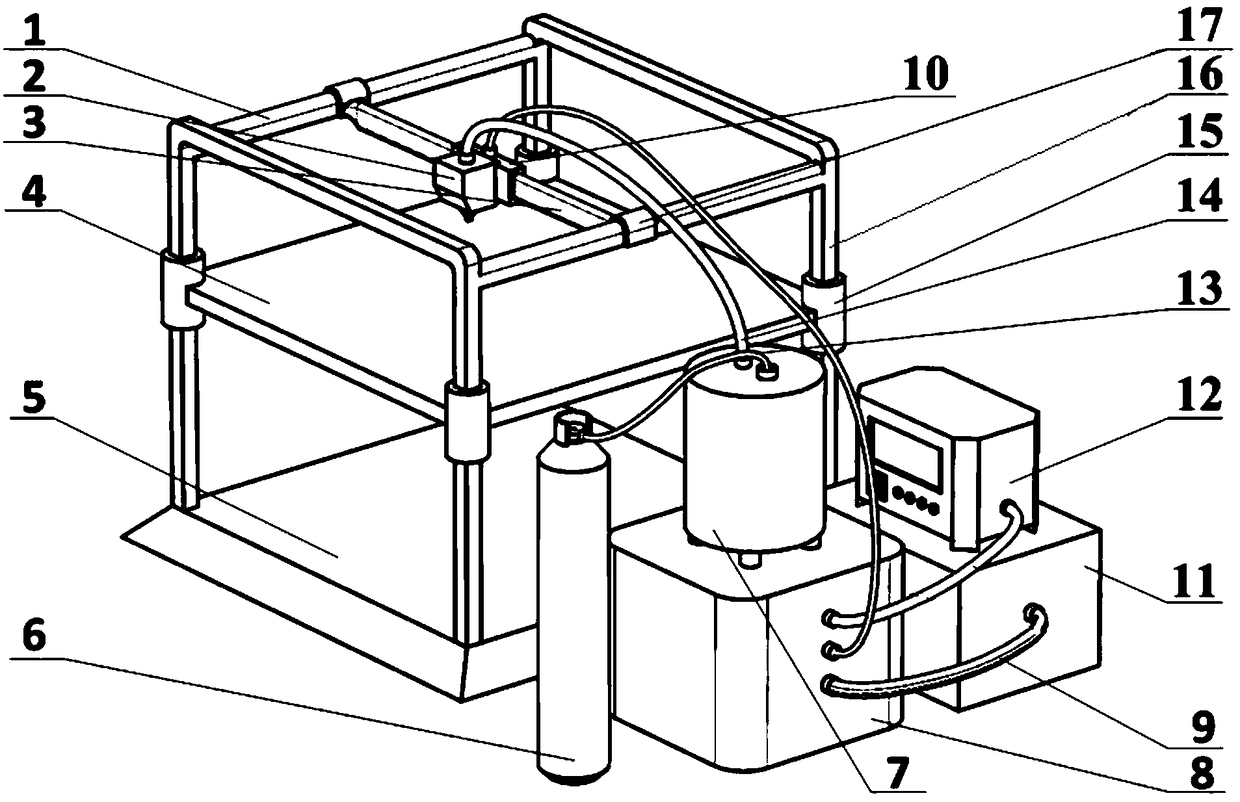

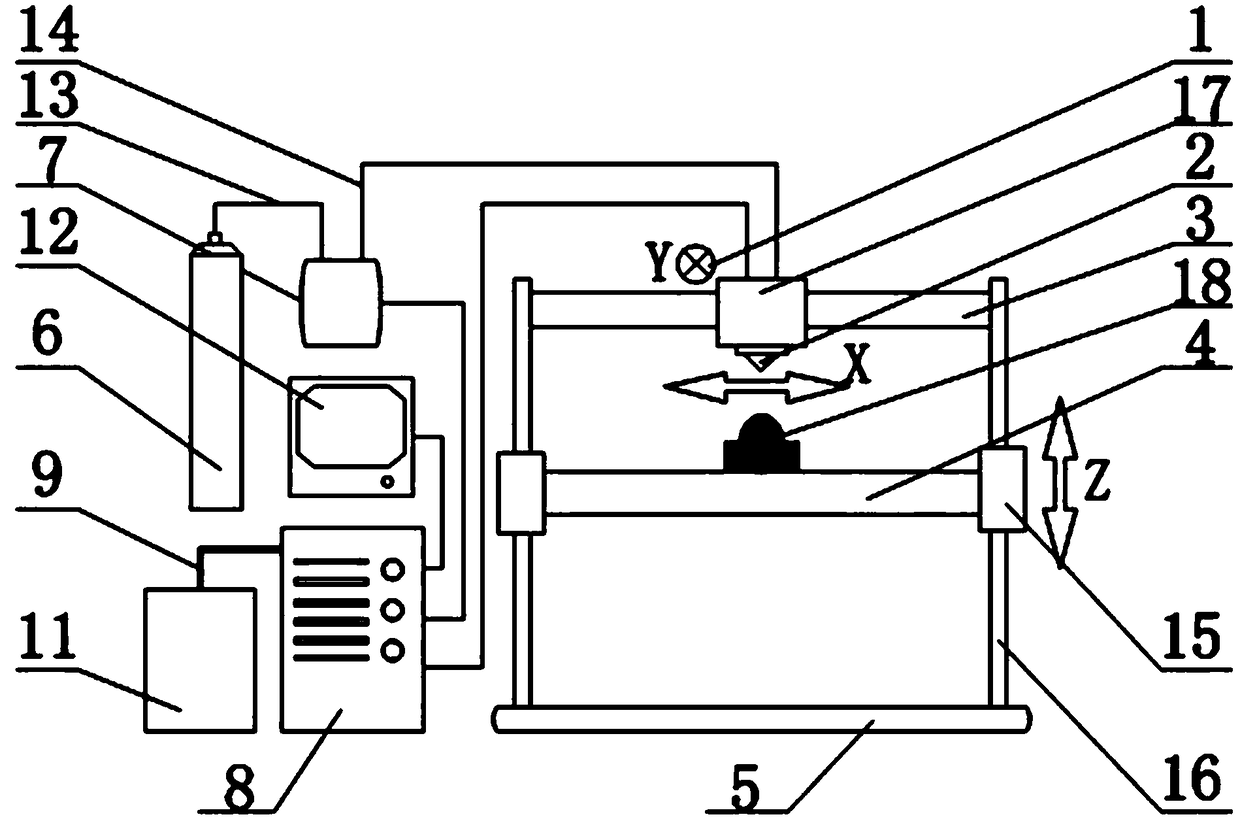

[0037] Such as figure 1 , 2 shown. The invention discloses a device for 3D printing architectural decoration, comprising a base 5, a Y-axis guide rail 1, an X-axis guide rail 3, a Z-axis guide rail 16, a mobile forming platform 4, a wire feeder 7, a CMT power supply system 8, and a water cooler 11. Protective gas device 7 and central control system 12;

[0038] There are four Z-axis guide rails 16, which stand upright symmetrically at the four corners of the base 5;

[0039] There are two Y-axis guide rails 1, and each Y-axis guide rail 1 is parallel to each other and horizontally erected on the ends of two Z-axis guide rails 16 corresponding to each other;

[0040] The X-axis guide rail 3 is one, and its two ends pass through the X-axis slider mechanism 17 arranged on the Y-axis guide rail 1, and are horizontally erected between two Y-axis guide rails 1, driven by the X-axis slider mechanism 17. The X-axis guide rail 3 reciprocates horizontally along the axis of the Y-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com