A kind of equipment and process for printing on beer kegs

A beer keg and printing technology, applied in printing, printing machines, printing devices, etc., can solve the problems of useless and troublesome replacement of font components, scrapping of semi-finished products, etc., to reduce production costs and time, save processes, and save time for changing characters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

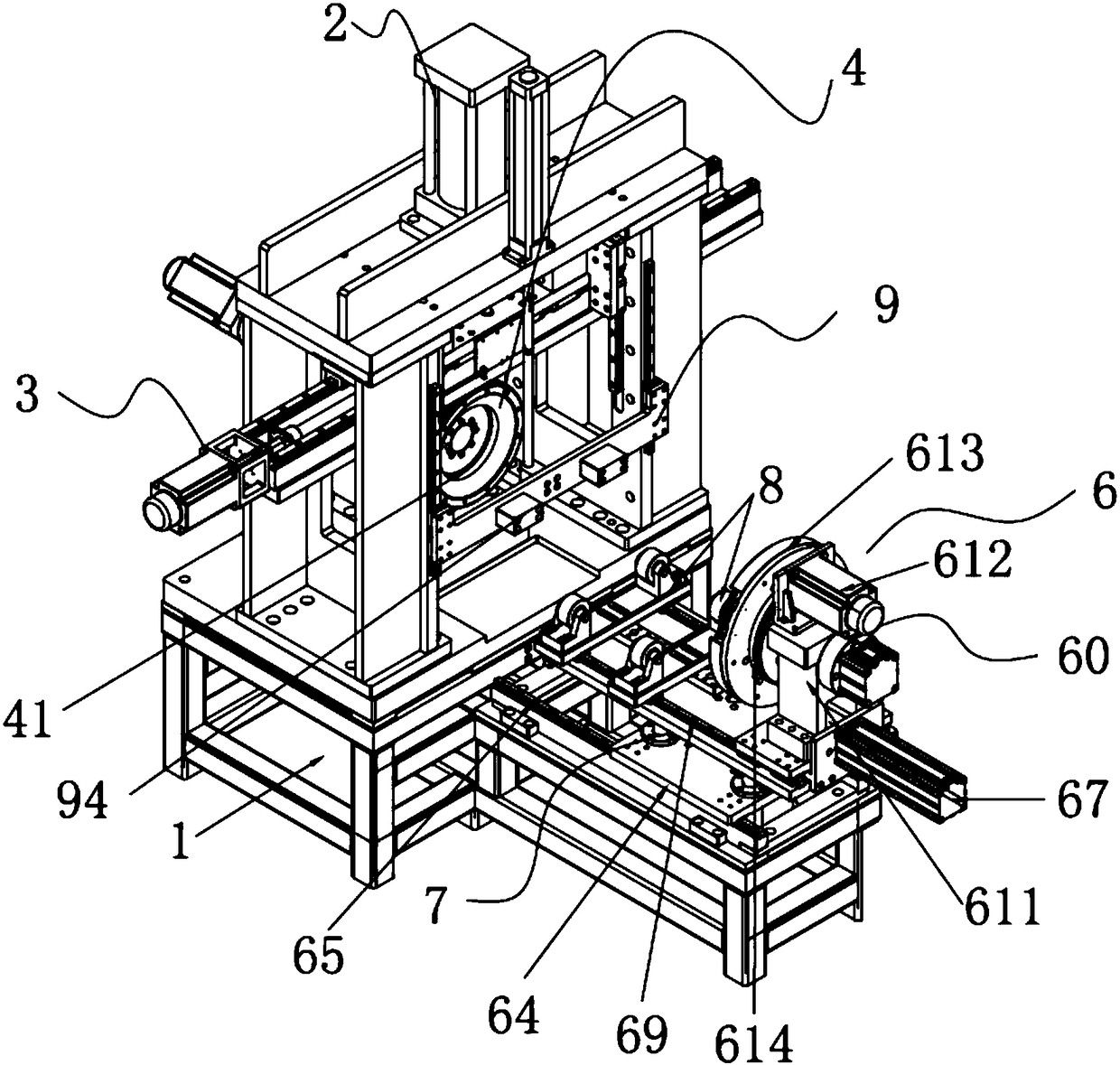

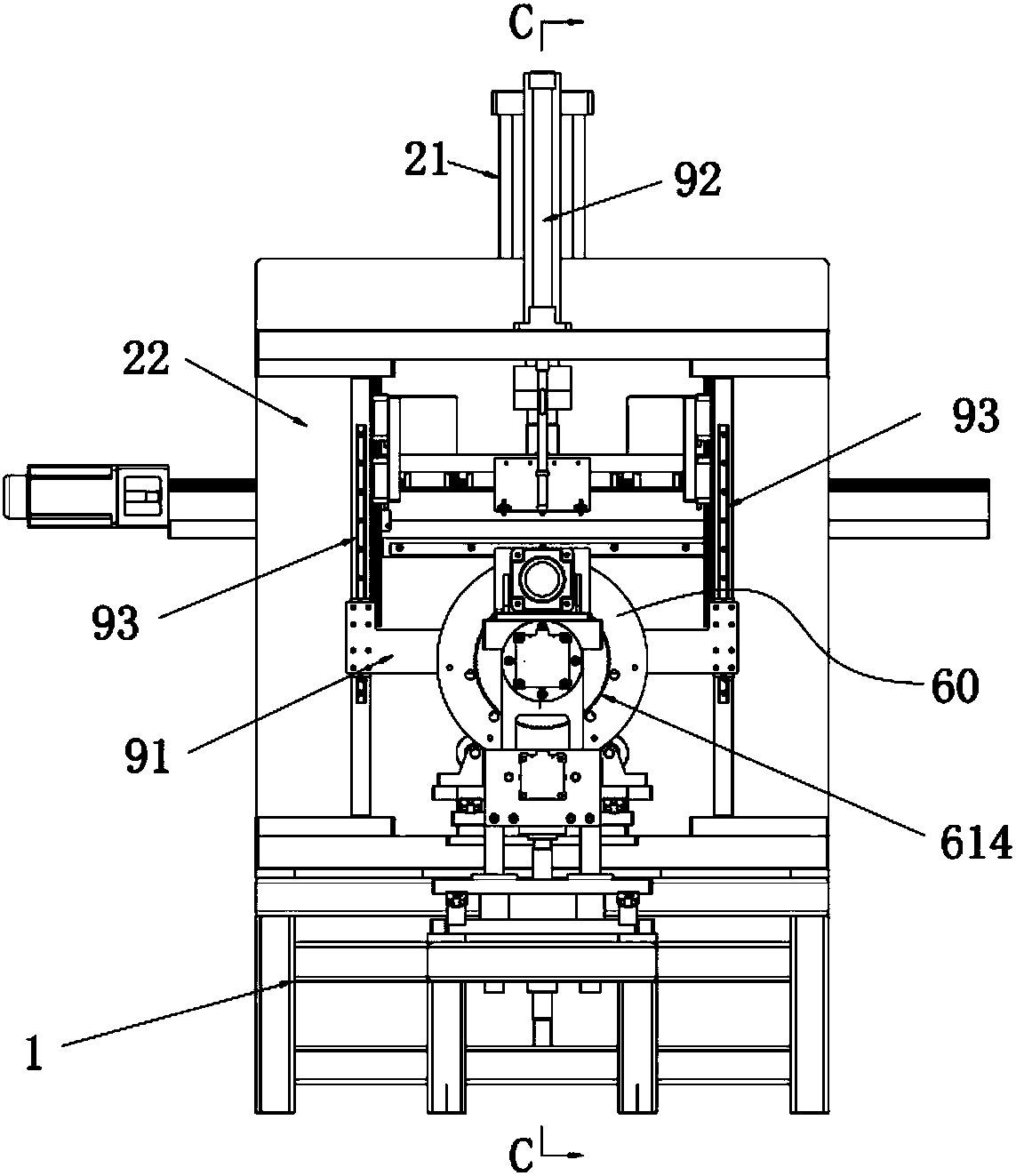

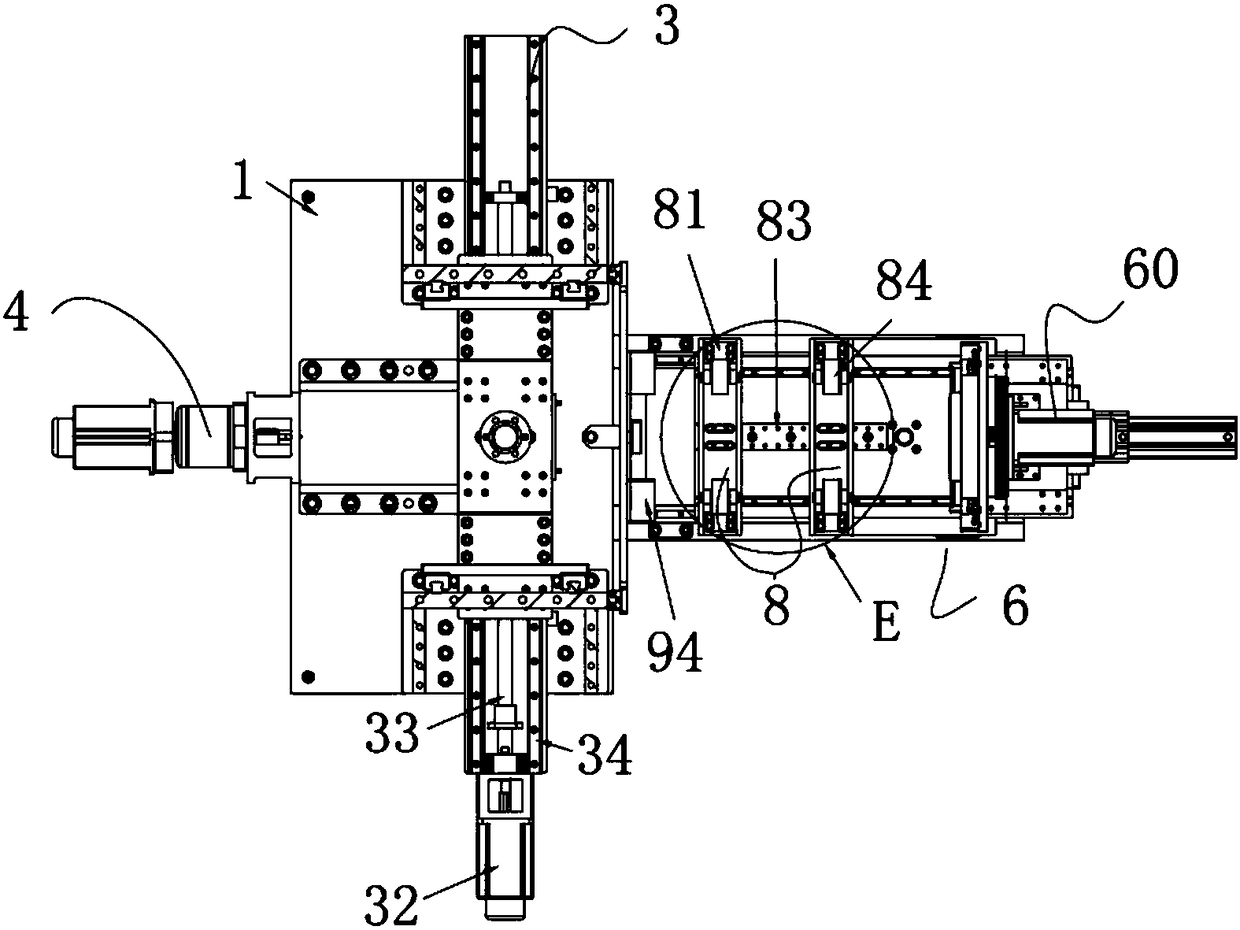

[0054] Example: as Figure 1-Figure 7 As shown, a device for printing on draft beer barrels includes a frame 1 and a separately controllable hydraulic pushing device 2 installed on the frame 1, a printing device 3 outside the barrel, a printing device 4 inside the barrel, and a beer barrel. The barrel drive mechanism 6 and several type modules; each type module includes a convex mold 61 and a concave mold 62 that cooperate to emboss a single character.

[0055] Such as figure 1 and Figure 4 As shown, the printing device 4 inside the wine barrel includes a turntable seat 41, a second servo motor 42 and a bearing bracket 43; the bearing bracket 43 is installed on the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com