A kind of equipment and process for printing on beer kegs

A beer keg and printing technology, applied in printing, printing presses, printing devices, etc., can solve the problems of useless printing process, scrapped semi-finished products, etc., to save the time of replacing molds, save processes, and achieve universality and interchangeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

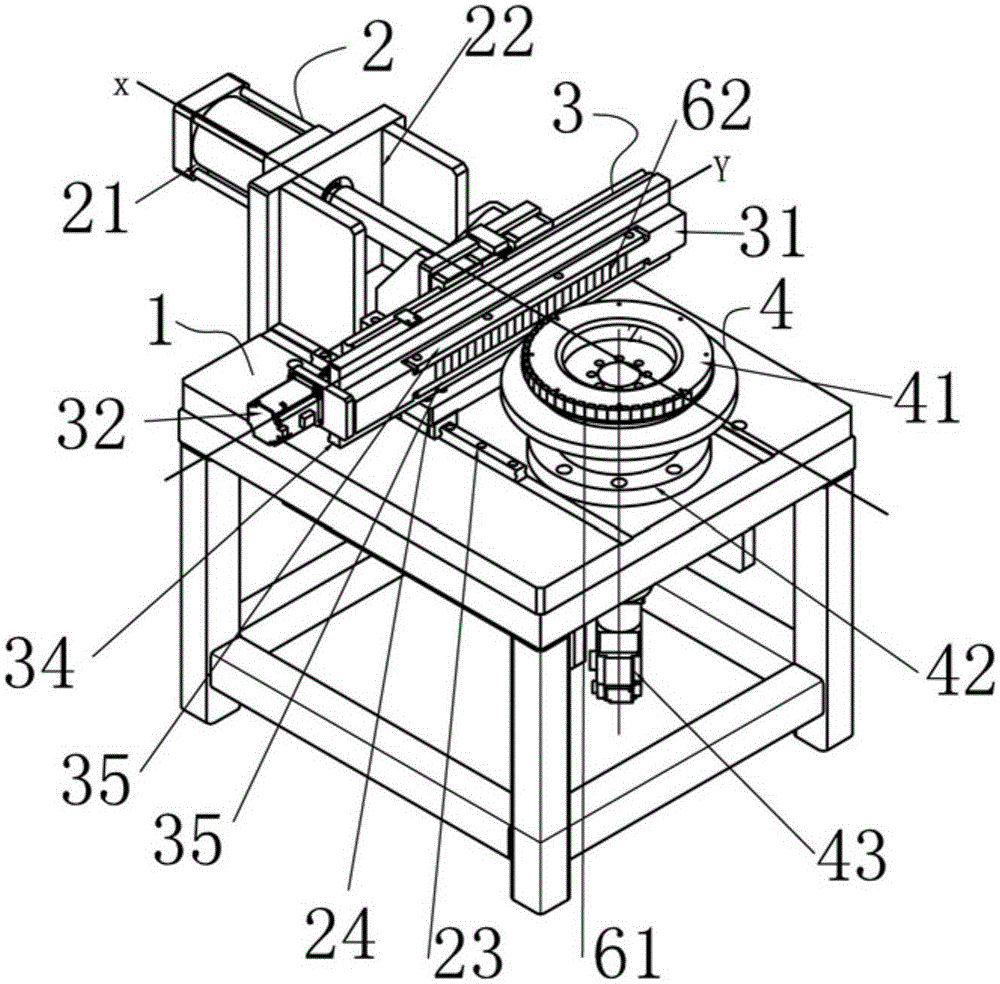

[0039] Embodiment one: as Figure 1-Figure 4The shown equipment for printing on draft beer kegs includes a workbench 1 and a hydraulic pusher 2 installed on the workbench 1, a printing device 3 outside the keg and a printing device 4 inside the keg; the hydraulic pusher 2 Including a hydraulic cylinder 21, a hydraulic cylinder mounting frame 22, a first guide rail 23 and a moving frame 24; the hydraulic cylinder 21 is installed on the workbench 1 through the hydraulic cylinder mounting frame 22, and the first guide rail 23 is laid on the On the table, the moving frame 24 is installed on the first guide rail 23 . The printing device 3 outside the wine barrel includes a connecting frame 31, a Y-axis servo motor 32, a screw 33 and a second guide rail 34; And the Y-axis servo motor 32 drives the screw rod 33 to rotate. One end of the connecting frame is installed on the second guide rail to slide and connect along the Y-axis, and one end is connected to the screw rod in a spiral ...

Embodiment 2

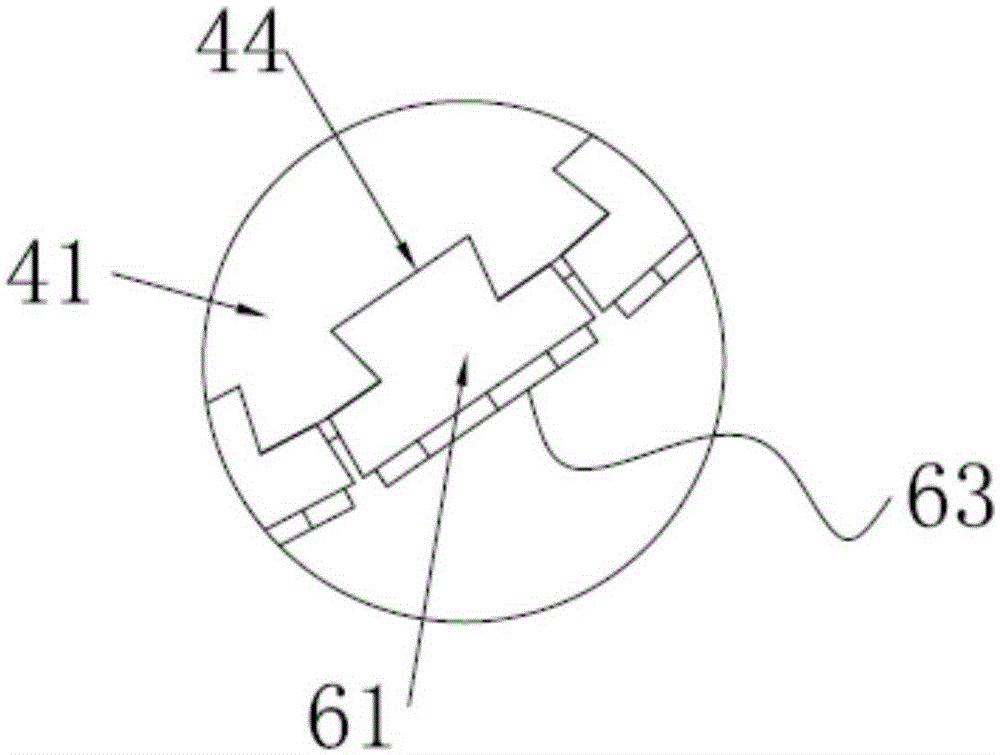

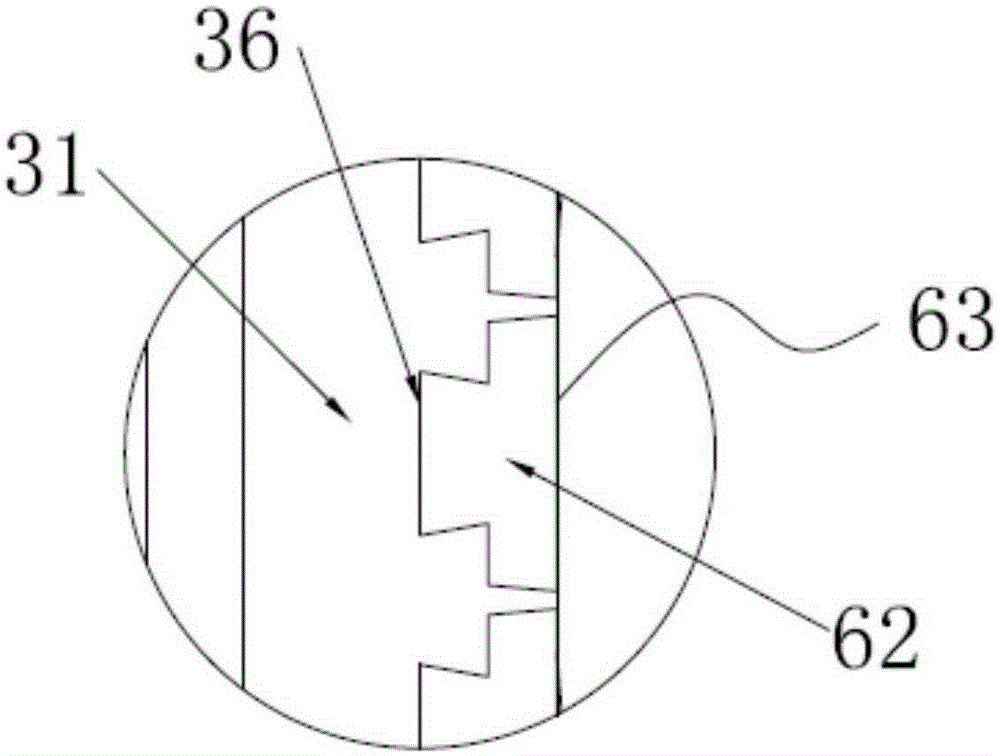

[0041] Embodiment two: if Figure 3-Figure 6 As shown, the inner mold 61 and the outer mold 62 are all designed to include at least one font 63, and the font 63 in the single inner mold 61 is paired with the font 63 in the single outer mold 62 to form a pair of embossed single characters. Font assembly; the circumferential surface of the turntable seat 41 and the Y-axis surface of the connecting frame 31 are all provided with one or more dovetail grooves 44,36, and when there are multiple dovetail grooves 44,36, the dovetail grooves 44,36 The size is the same, and the size of each font 63 is the same. The back of the font 63 is snapped into the dovetail groove 44 so that the font 63 is installed on the Y-axis surface of the connecting frame 31 and the circumferential surface of the turntable seat 41 respectively. Assuming that the logo we need to print is "ABCD", and the design of the inner mold 61 and outer mold 62 of the traditional printing mold is a conjoined font 63 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com