A kind of high-performance conductive ceramic material and preparation method thereof

A conductive ceramic material and high-performance technology, which is applied in the field of conductive oxide and high-performance conductive ceramic material formulation, can solve the problems of high sintering temperature and low density, achieve good conductivity, non-toxic performance, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

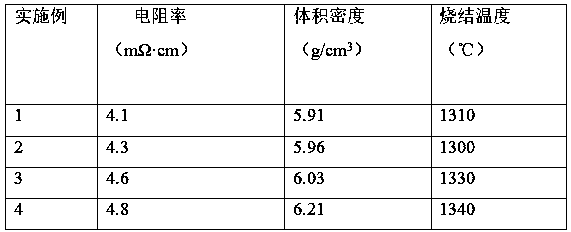

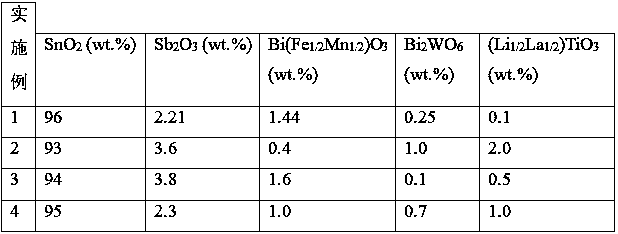

[0020] The present invention is described further in conjunction with embodiment now, and table 1 provides the formula of altogether 4 samples of the embodiment of the present invention.

[0021] The main raw material of the formula of the embodiment of the present invention totally 4 samples adopts conventional chemical pure raw material, at first adopts conventional chemical raw material to synthesize Bi respectively with solid-phase method during preparation 2 WO 6 , Bi(Fe 1 / 2 mn 1 / 2 )O 3 , (Li 1 / 2 La 1 / 2 )TiO 3 , and then mix the ingredients according to the above formula, mix the prepared materials with absolute ethanol by ball milling with a planetary ball mill, material: ball: absolute ethanol = 1:3: (0.6~1.3) (mass ratio), after ball milling for 4~8 hours , drying to obtain dry powder, adding polyvinyl alcohol solution with a concentration of 10% (mass percentage) accounting for 8% to 10% of its mass in the dry powder, granulating, mixing and grinding, passing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com