A concrete prefabricated foundation

A prefabricated, concrete technology, applied in infrastructure engineering, construction, etc., can solve the problems of small base area of composite structure, uneven bottom surface of foundation pit, and many connecting bolts, etc., to save concrete consumption, increase self-weight, and reduce site The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the drawings.

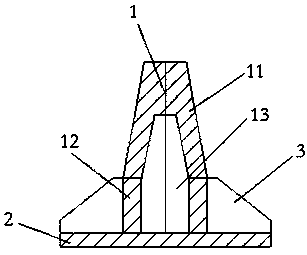

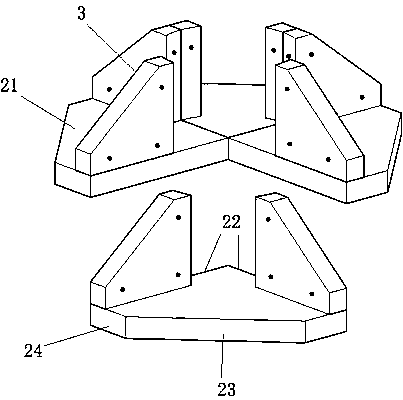

[0031] Such as figure 1 As shown, the tile assembly type foundation of the present invention includes a column 1, a bottom plate 2 and a rib beam 3. The column 1 is arranged above the middle of the bottom plate 2. The ribs 3 are in four groups, distributed evenly on the outer circumference of the column in a radial shape, and are fixed on the upper end surface of the bottom plate 2.

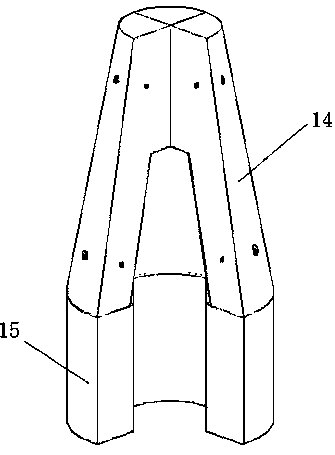

[0032] Combine figure 2 , The column 1 includes upper and lower layers, the upper layer is a truncated cone 11, and the lower layer is a hollow cylinder 12. The lower part of the truncated cone 11 is hollow and communicates with the hollow part of the lower hollow cylinder 12 to form a cylindrical hollow part 13 together. The truncated cone 11 is composed of four frustum tiles 14 of the same size, and the four frustum tiles 14 are symmetrically distributed along the central axis of the truncated cone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com