Tunnel dust collector

A technology for dust removal trucks and tunnels, which is used in dust prevention, safety devices, mining equipment, etc. It can solve the problems that dust cannot be completely removed and the operation effect is not good enough. It can meet the requirements of high-efficiency operation, meet the requirements of small radius and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

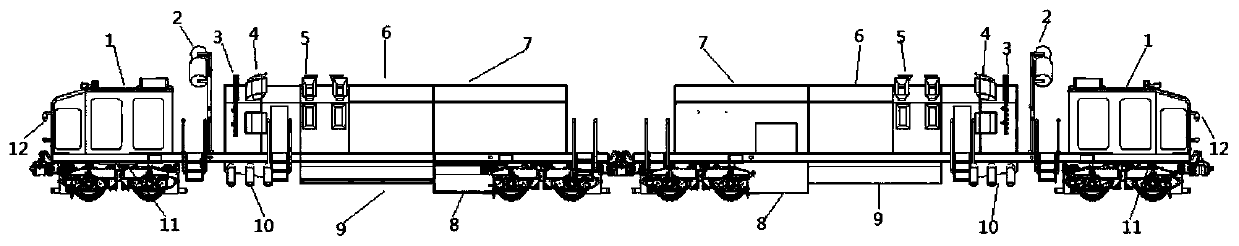

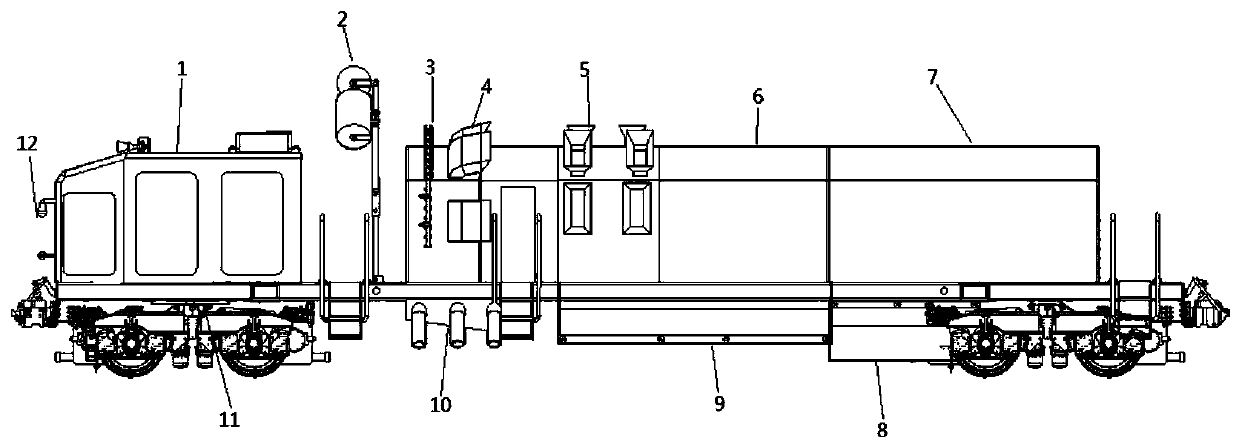

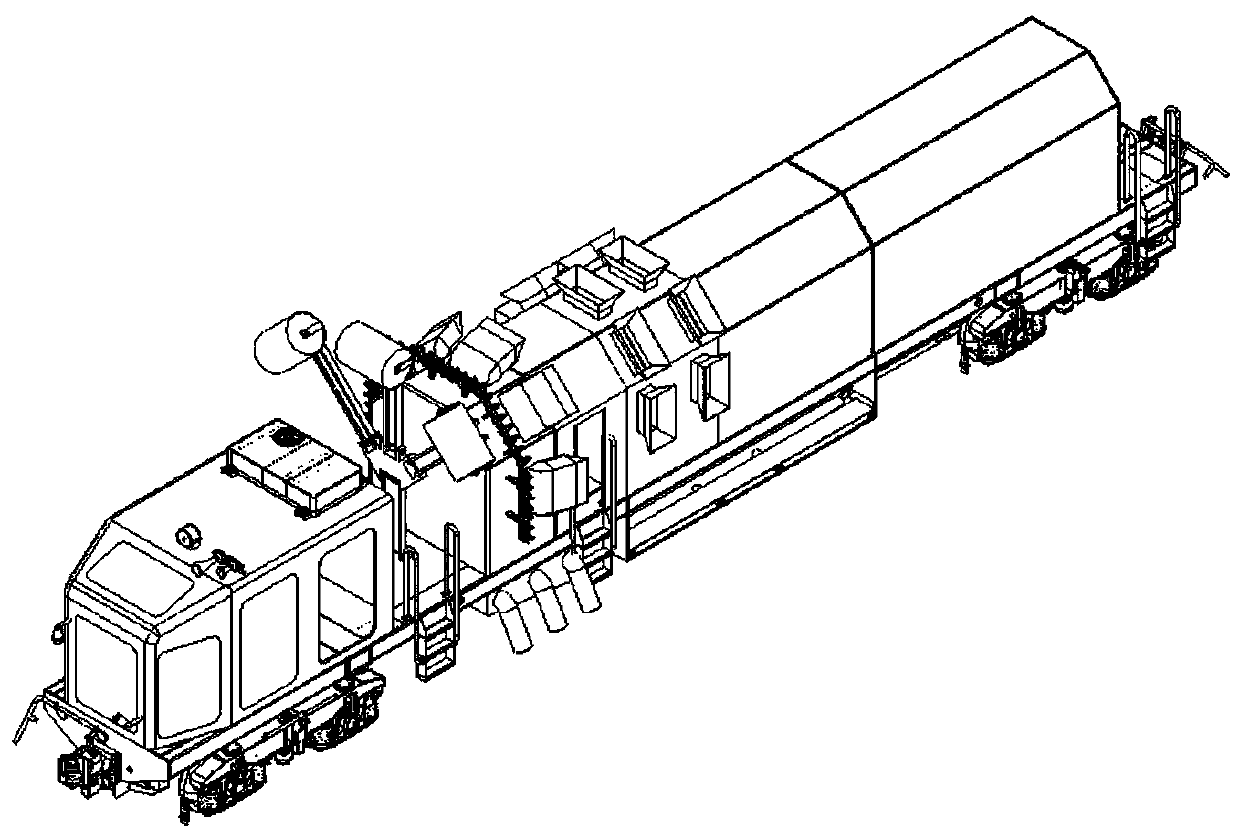

[0067] Embodiment 1.1: tunnel dedusting vehicle, such as Figure 1-11 As shown, it includes two operating vehicles, and the two operating vehicles are symmetrically arranged with respect to the transverse center line of the operating vehicle. The front end of the upper frame of the operating vehicle is provided with a driver's cab 1, and the frame behind the driver's cab 1 is provided with rollers. Hairbrush 2, the lower part of the vehicle frame behind the roller brush 2 is sequentially equipped with a ballast bed dirt suction cabin 10, a dirt suction box dirt collection cabin 9 and a spare dirt collection cabin 8, the vehicle frame behind the roller hair brush 2 The upper part is provided with a high-pressure jet head 3, a large-volume air outlet 4, and a large-air volume suction port 5 from front to back, and a dust filter cabin 6 and a water storage tank 7 are sequentially installed on the vehicle frame behind the large-air volume suction port 5. The brush 2 is a retractab...

Embodiment 12

[0093] Embodiment 1.2: Tunnel dedusting vehicle, with embodiment 1.1, difference is: described roller hairbrush horizontal single row 5.

Embodiment 21

[0094] Embodiment 2.1: tunnel dedusting car, with embodiment 1.1, difference is: as Figure 12As shown, the sewage collection cabin 9 of the suction box is a drawer-type integrated warehouse, which adopts a split drawer design and a stacking design. A dust drop opening is set in the dust filter warehouse, and a pressure sensor is installed under the drawer corresponding to the drop opening. When the pressure sensor detects that the pressure value reaches the weight value of a single drawer, the drawer will automatically shift, and the next empty drawer will be replenished to the position where the dust falls. The horizontal and vertical displacement of each drawer is realized by a mechanical chain.

[0095] The working method of the tunnel dedusting vehicle provided by the above-mentioned embodiment is: the tunnel dedusting vehicle is connected and operated to the road section to be operated, firstly the roller brush 2 is stretched out, and the pressure sensor installed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com