Piston ring of internal combustion engine and internal combustion engine provided with piston ring

A technology for piston rings and internal combustion engines, applied to piston rings, machines/engines, mechanical equipment, etc., to achieve the effects of reducing wear, reducing wear and friction power consumption, and increasing oil film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, in which the same reference numerals represent the same or similar parts. The accompanying drawings are only used to illustrate the present invention, and do not represent the actual structure and true scale of the present invention.

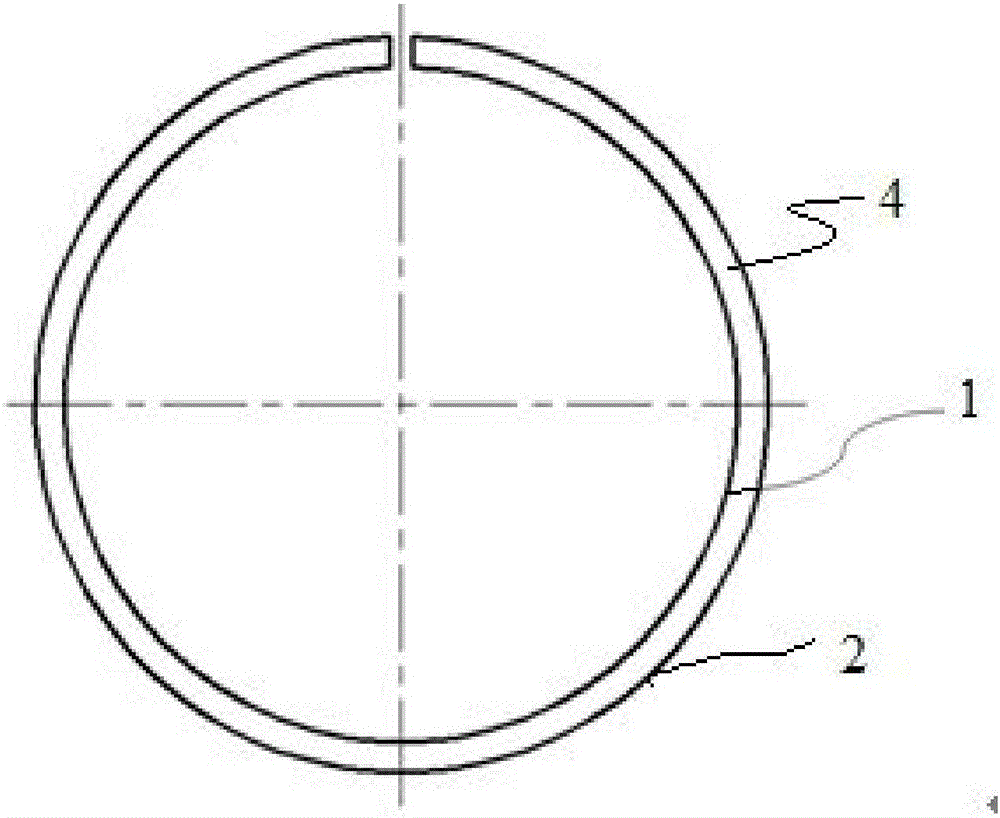

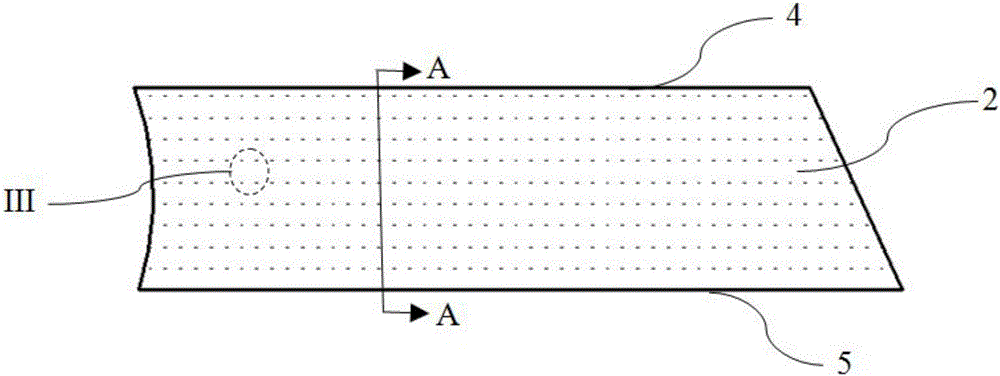

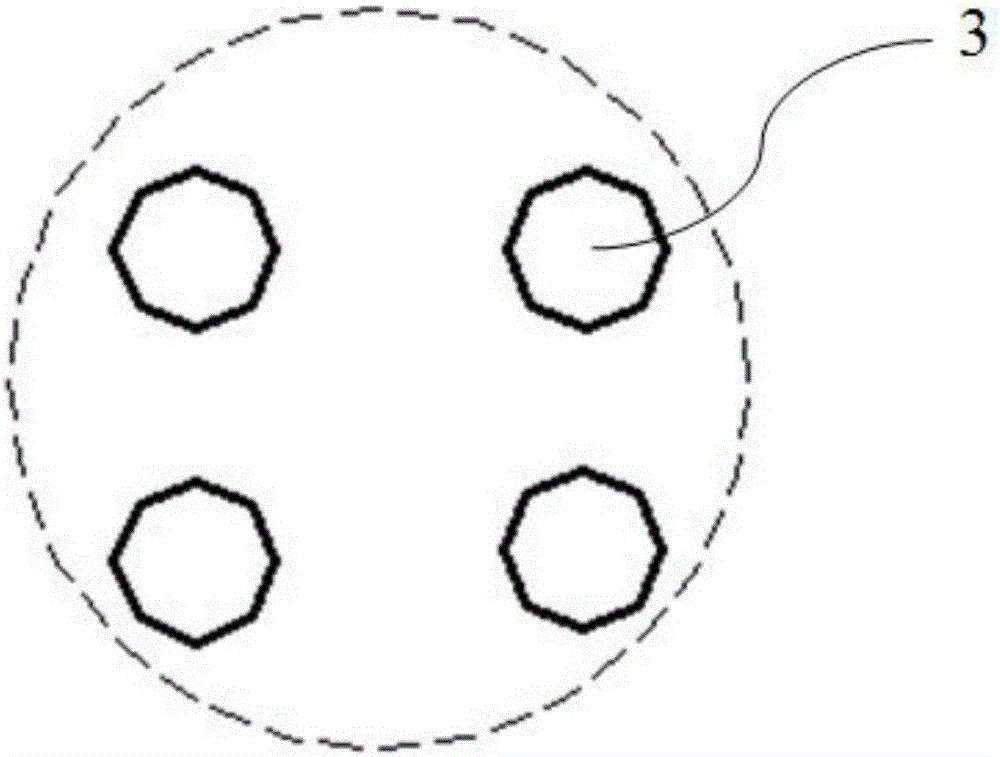

[0026] figure 1 Shown is a kind of schematic diagram of internal combustion engine piston ring of the present invention, described piston ring 1 comprises piston ring outer surface 2, piston ring upper end surface 4 and piston ring lower end surface 5; The upper end surface 4 of the piston ring and the lower end surface 5 of the piston ring are perpendicular to each other. On the outer surface 2 of the piston ring, several micro-dimple structures 3 with different depths are processed by laser machining or o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius r | aaaaa | aaaaa |

| Radius r | aaaaa | aaaaa |

| Maximum depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com