Oil separation method and oil separation device for a hydrodynamic thrust bearing

A technology of thrust bearing and hydrodynamic pressure, which is applied in the direction of bearing components, shafts and bearings, bearing cooling, etc., can solve the problems of increased space occupied by thrust bearings, increased manufacturing materials of thrust bearings, and increased working oil temperature of bearings, etc., to achieve Reduce space occupation area, reduce manufacturing cost, improve the effect of oil separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

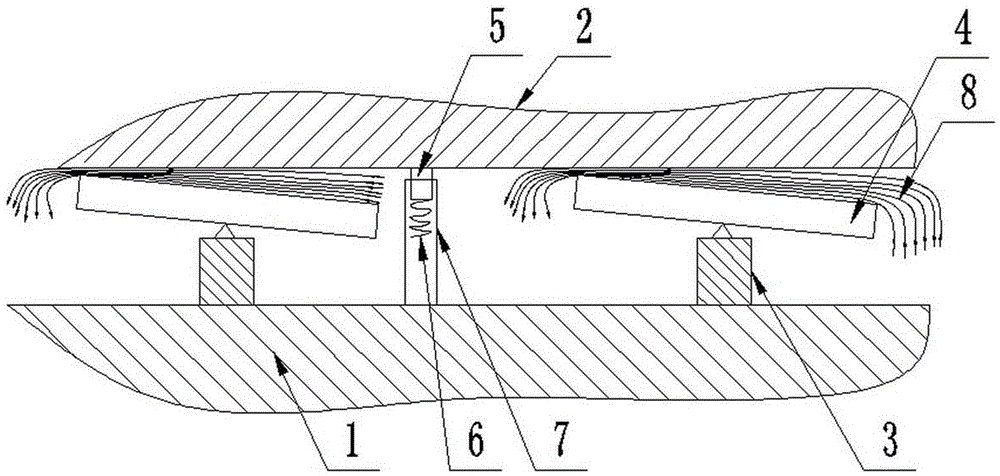

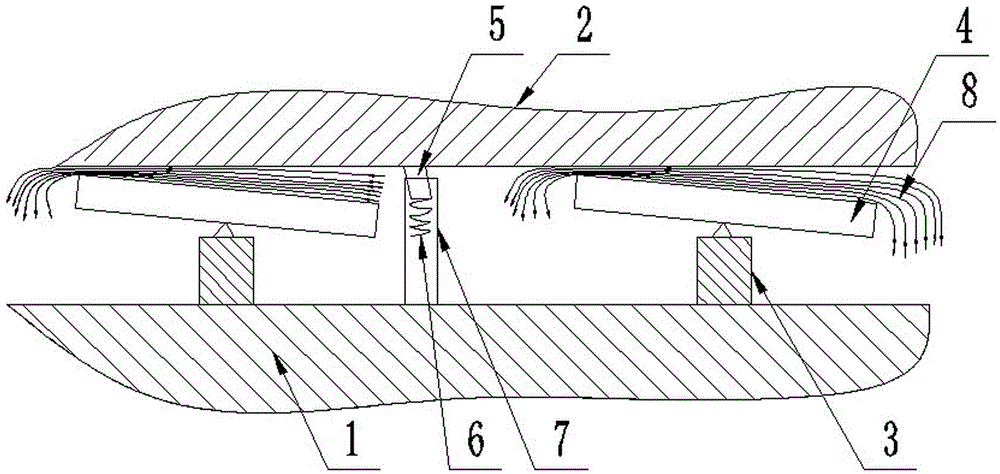

[0028] An oil separation method for a hydrodynamic thrust bearing. When the hydrodynamic thrust bearing is working, the rotating shaft in the thrust bearing drives the mirror plate 2 to rotate. At this time, cold oil enters the bearing bush 4 and the mirror plate 2 from the oil inlet end of the bearing bush 4 Between, and under the driving of the rotating mirror plate 2, an oil film is formed between the bearing bush 4 and the mirror plate 2. Since there is friction between the rotating mirror plate 2 and the oil film, the friction of the cold oil on the rotating mirror plate 2 It turns into hot oil and flows from the oil outlet end of the bearing pad 4 to the oil inlet end of the next bearing pad 4 driven by the mirror plate 2. Before the hot oil enters the last bearing pad 4, the An oil separation device is set between the last bearing bush 4 to cooperate with the working surface of the mirror plate 2 to make the hot oil flow into the oil groove 1 below the bearing bush 4, an...

Embodiment 2

[0030] An oil separation device for a hydrodynamic thrust bearing, comprising a rotating shaft, a mirror plate 2, a bearing seat 3 and a bearing bush 4, the rotating shaft is fixed in the oil tank 1 and fixedly connected with the mirror plate 2 to drive the mirror plate 2 to rotate, and the bearing seat 3 Fixed in the oil tank 1, the number of bearing pads 4 is multiple, distributed around the rotating shaft through the bearing seat 3, and the bearing pads 4 are arranged obliquely under the working surface of the mirror plate 2, and form a wedge-shaped gap with the mirror plate 2 in the forward direction. The large opening side 8 of the wedge-shaped gap is the oil inlet end, and the small opening side of the wedge-shaped gap is the oil outlet end; the oil separation device is arranged between two adjacent bearing bushes 4, and the oil separation device includes an oil separation plate 5 and a support frame 7. The support frame 7 is fixed on the bottom of the oil tank 1, the low...

Embodiment 3

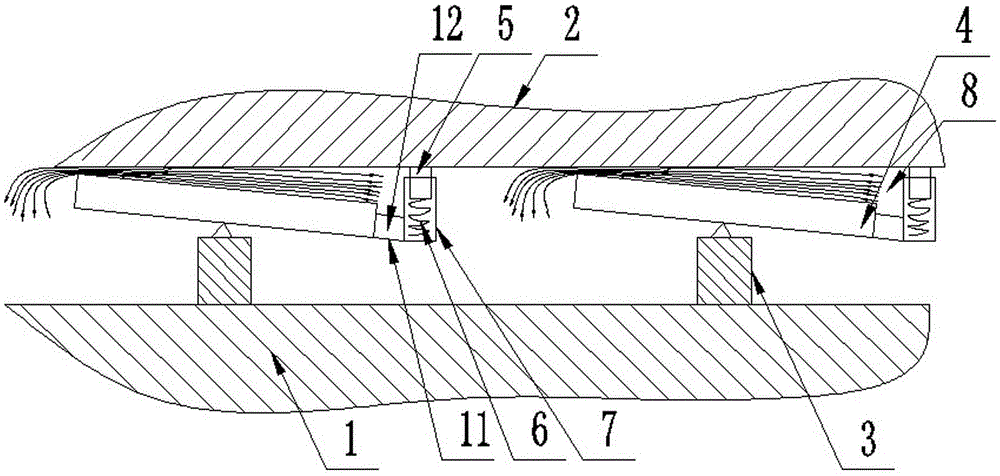

[0035] This embodiment is basically the same as the above-mentioned embodiment, the main difference is that: the support frame 7 is fixed on the bearing bush 4 on the side of the large opening of the wedge-shaped gap through the connecting piece 11, and there is an oil inlet passage 12 between the support frame 7 and the bearing bush 4. Oil enters the bearing bush 4 from the oil inlet channel 12 between the support frame 7 and the bearing bush 4 . In the existing thrust bearings, the bearing bush 4 can automatically and slightly adjust the thickness of the oil film according to the bearing load. Therefore, the structure in which the support frame 7 is fixed on the oil inlet side of the bearing bush 4 can also automatically and slightly adjust the oil separator 5 and the mirror. Contact force between plates 2. However, the above-mentioned embodiment is preferred, and is not limited to the above-mentioned preferred embodiment. For example, the support frame 7 can be arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com