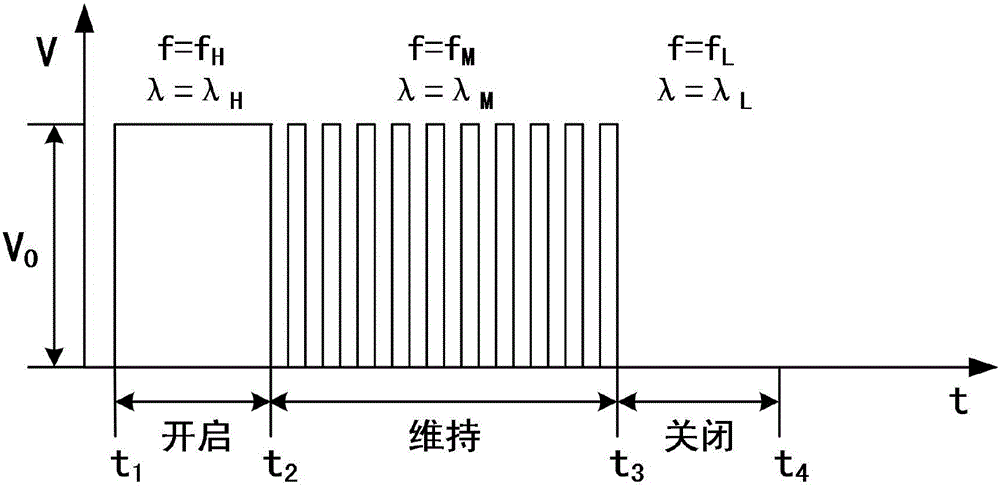

PWM control method for increasing response speed of high-speed on-off solenoid valve

A technology of high-speed switch and control method, applied in the direction of valve operation/release device, valve detail, valve device, etc., can solve problems such as prolonging the total closing time, reduce power consumption and closing delay, and reduce closing delay , the effect of reducing the turn-on delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

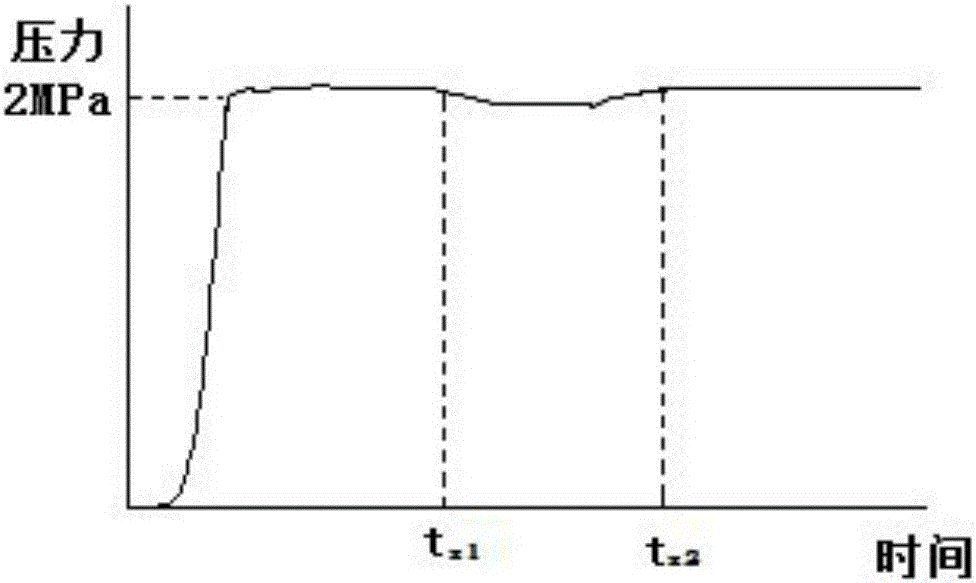

[0057] Embodiment: This embodiment uses the control method of the present invention to drive and control a certain type of high-speed switching solenoid valve. The parameters of this type of high-speed switching solenoid valve are as follows: the operating frequency range is 200HZ~1KHZ, the rated operating voltage is 12V, and the number of coil turns is 526 turns, the diameter of the moving armature is 9mm, the initial air gap is 2.2mm, and the non-working air gap is 0.2mm. The maximum displacement of the spool is 1.0mm, the moving mass is 0.0045kg, the coil resistance is 6 ohms, the spring precompression is 2.0mm, and the spring stiffness is 1300N m -1 , the viscous damping coefficient is 1.4N·m·s -1 , the hydrodynamic coefficient is 0.005×2E6N m -1 , the vacuum permeability is 4πE-7H·m -1 , Coverage is 0.5mm.

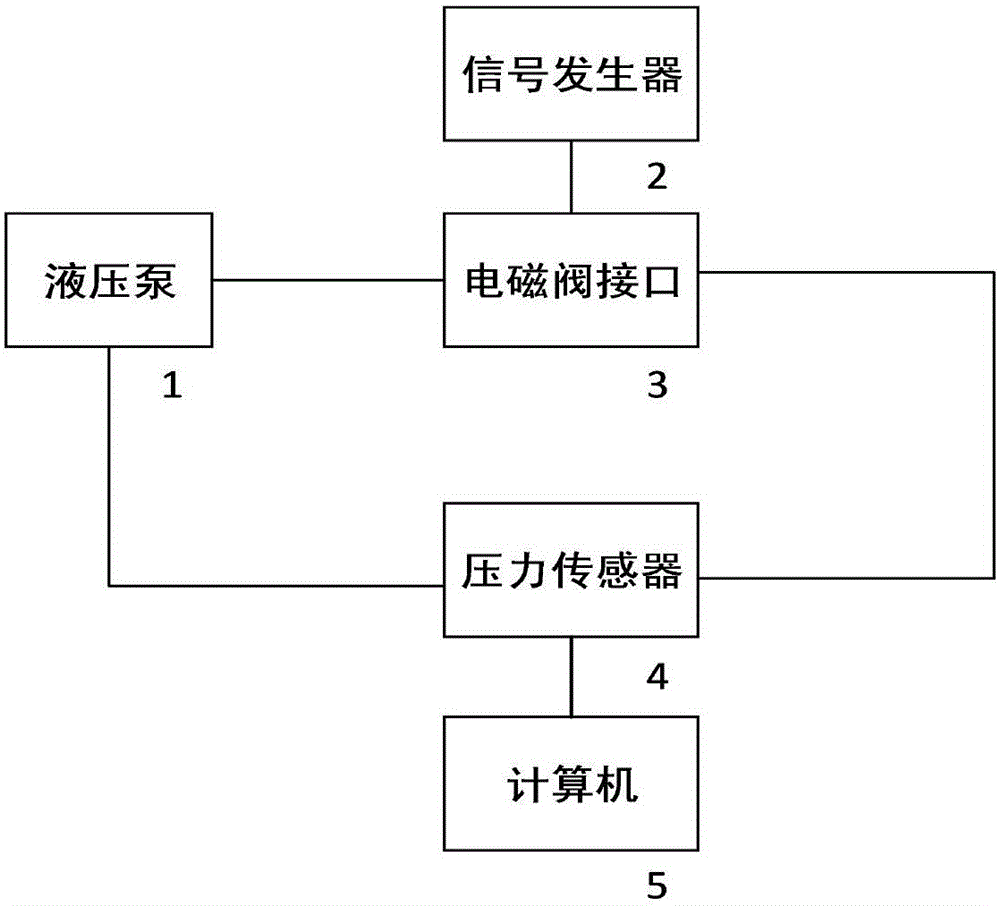

[0058] Such as figure 2 In the solenoid valve hydraulic test system shown, 1 is a hydraulic pump for generating hydraulic pressure, 2 is a PWM signal generator f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com