High resolution 3D phase microscopy imaging device and imaging method

A high-resolution, phase microscopy technique, applied in measurement devices, optical devices, instruments, etc., can solve the problems of impossible samples, inability to detect the refractive index of the sample, that is, the phase distribution, and slow imaging speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

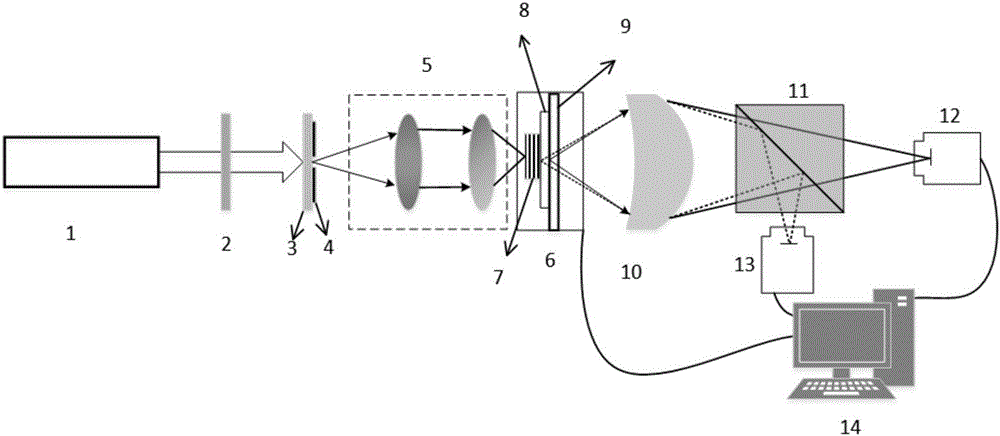

[0067] see first figure 1 , figure 1 It is a diagram of the high-resolution three-dimensional phase microscopic imaging device of the present invention. It can be seen from the figure that the high-resolution three-dimensional phase microscopic imaging device of the present invention includes a coherent light source 1, a two-dimensional electric translation stage 6 moving perpendicular to the optical axis, a first detector 12 and a computer 14, and is characterized in that there are also attenuation plates 2, Ground glass 3, pinhole diaphragm 4, 4F zoom system 5, standard glass plate 8, resolution plate 9, micromagnification system 10, beam splitting prism 11 and second detector 13, the positional relationship of the above-mentioned components is as follows:

[0068] Al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com