Monocrystalline silicon substrate TFT device

A monocrystalline silicon and substrate technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., can solve problems such as performance gaps and achieve the effect of reducing pixel size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

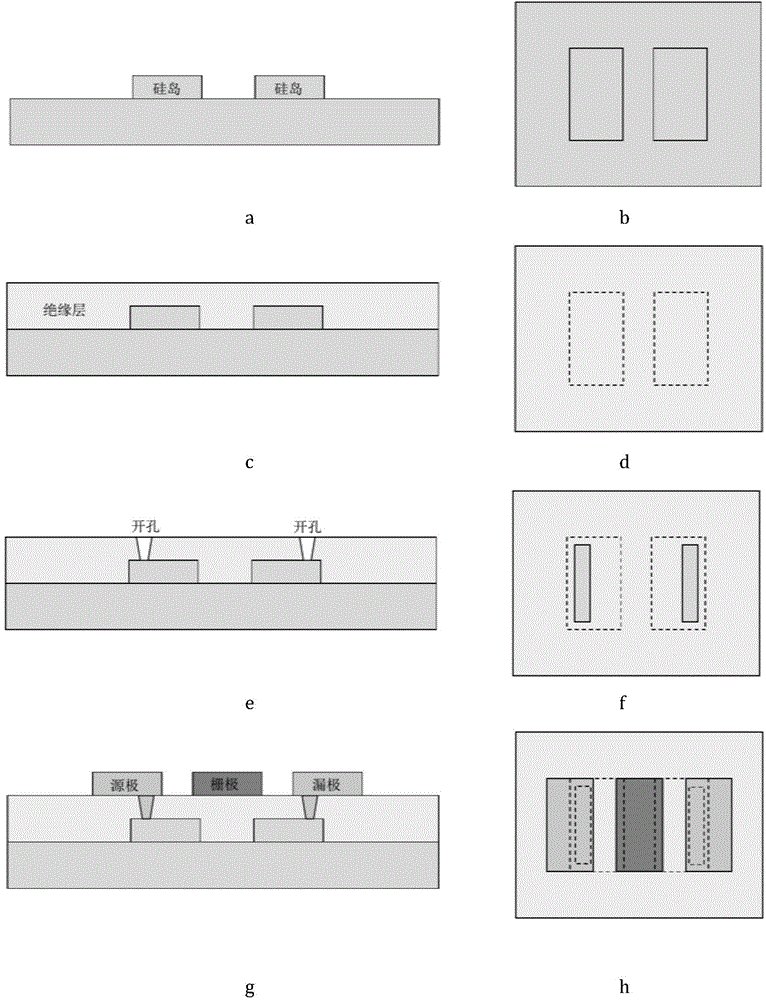

[0022] Such as figure 1 As shown in a to h, this embodiment includes the following steps:

[0023] 1. If figure 1 a and figure 1 As shown in b, the silicon island is etched on the single crystal silicon substrate. The etching method can be directly etched by laser beam, or ion beam etching can be used after covering the protective layer on the single crystal silicon substrate, or other etching methods can be used method. The size of the silicon island to be etched depends on the design requirements of the device.

[0024] 2. If figure 1 c and figure 1 As shown in d, the etched silicon island is covered with a layer of insulating material, which can be done by evaporation or magnetron sputtering, or by sol-gel method. The insulating material can be inorganic substances such as metal oxides and metal salts, or organic materials. The insulating material used should have good adhesion to the single crystal silicon substrate and be compatible with the subsequent process. sex...

Embodiment 2

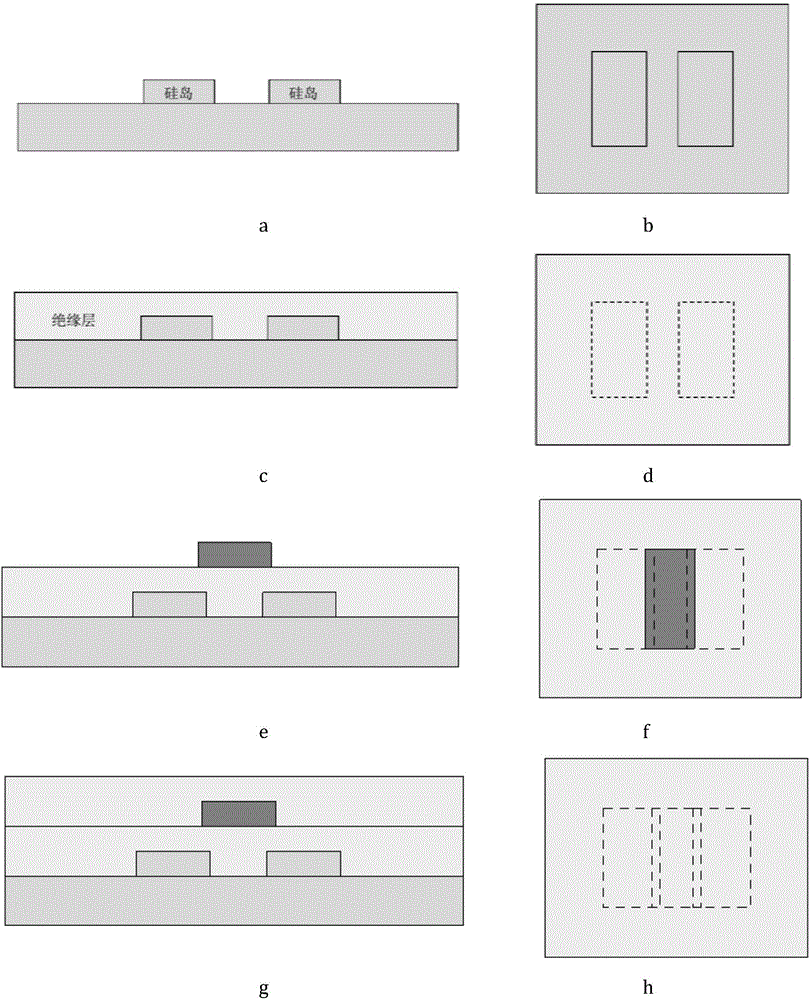

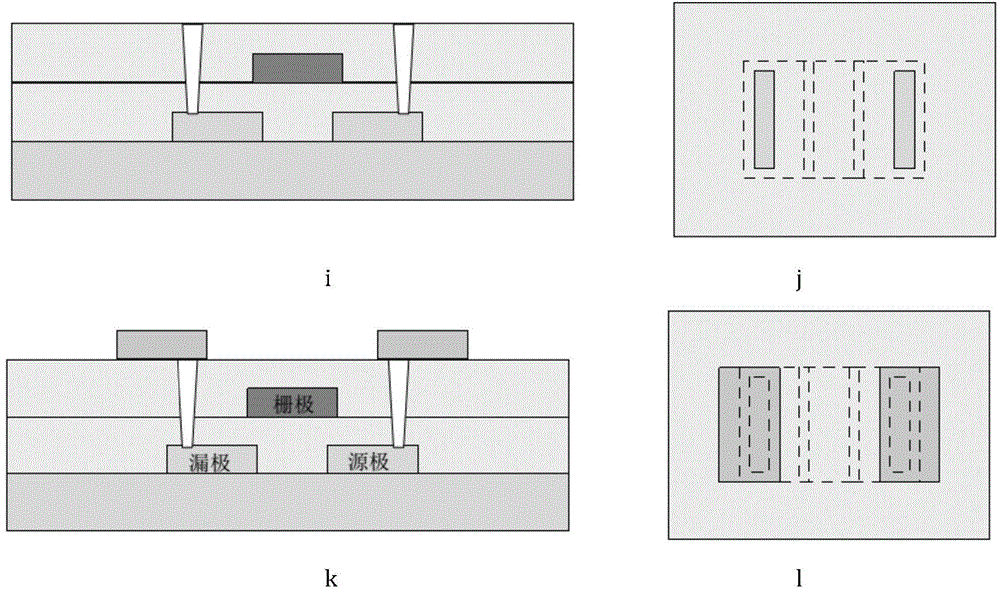

[0029] Such as figure 2 Shown in a~l, this embodiment includes the following steps:

[0030] 1. If figure 2 a and figure 2 As shown in b, the silicon island is etched on the single crystal silicon substrate. The etching method can be directly etched by laser beam, or ion beam etching can be used after covering the protective layer on the single crystal silicon substrate, or other etching methods can be used method. The size of the silicon island to be etched depends on the design requirements of the device.

[0031] 2. If figure 2 c and figure 2 As shown in d, the etched silicon island is covered with a layer of insulating material, which can be done by evaporation or magnetron sputtering, or by sol-gel method. The insulating material can be inorganic substances such as metal oxides and metal salts, or organic materials. The insulating material used should have good adhesion to the single crystal silicon substrate and be compatible with the subsequent process. sex....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com