A New Contact Measuring Device for Plate Curvature

A contact measurement, a new type of plate technology, applied in the direction of measurement devices, instruments, etc., can solve the problems of backward measurement technology, achieve the effect of fast calculation speed, wide application, and improve processing speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

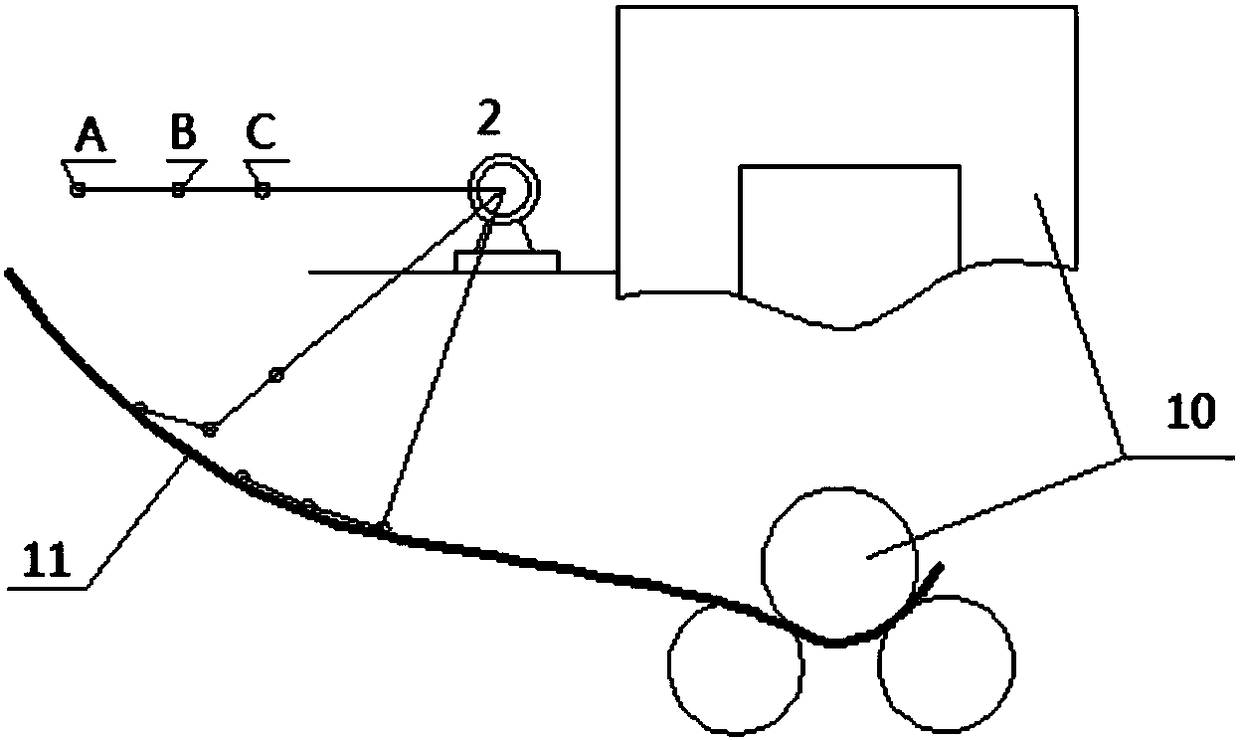

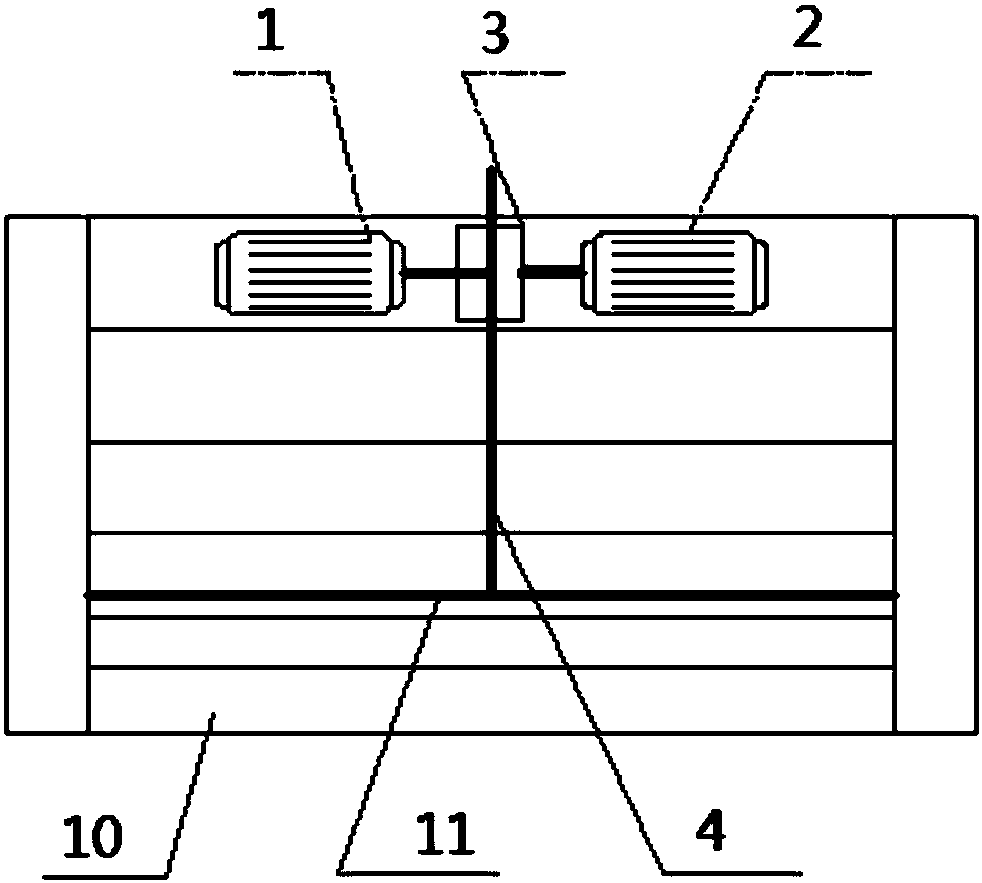

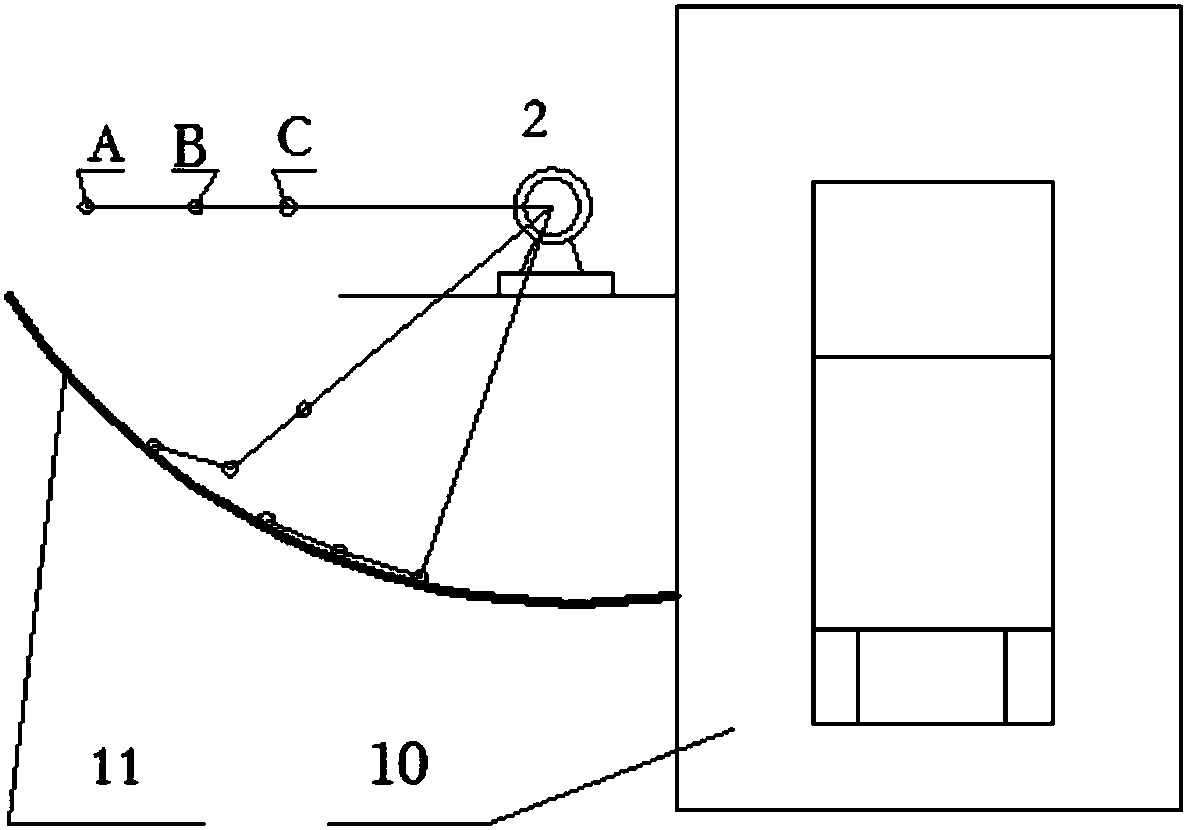

[0029] The invention researches the measurement method of sheet curvature, and invents a new type of sheet curvature contact measuring device for the roll bending machine, that is, the three contacts of the measuring device are in contact with the sheet, and the measurement on both sides can be measured by the angle encoder The angle of the point relative to the middle point, where the distance between the measured points on both sides and the middle point is a fixed value, and the radius of curvature of the sheet metal forming can be obtained through the calculation of the trigonometric function.

[0030] In the following, the innovative specific implementation of the present invention will be further described with reference to the implementation examples and the drawings.

[0031] The new plate curvature contact measuring device (hereinafter referred to as the measuring device) provided by the present invention has a structure such as figure 1 with figure 2 As shown, it includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com