A programmable universal capacitive liquid level sensor controller and its control method

A sensor controller and sensor technology, which is applied in general control systems, program control, liquid level indicators for physical variable measurement, etc., can solve the problems of high price and high cost, and achieve good human-computer interaction and convenient operation , Improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in conjunction with accompanying drawing:

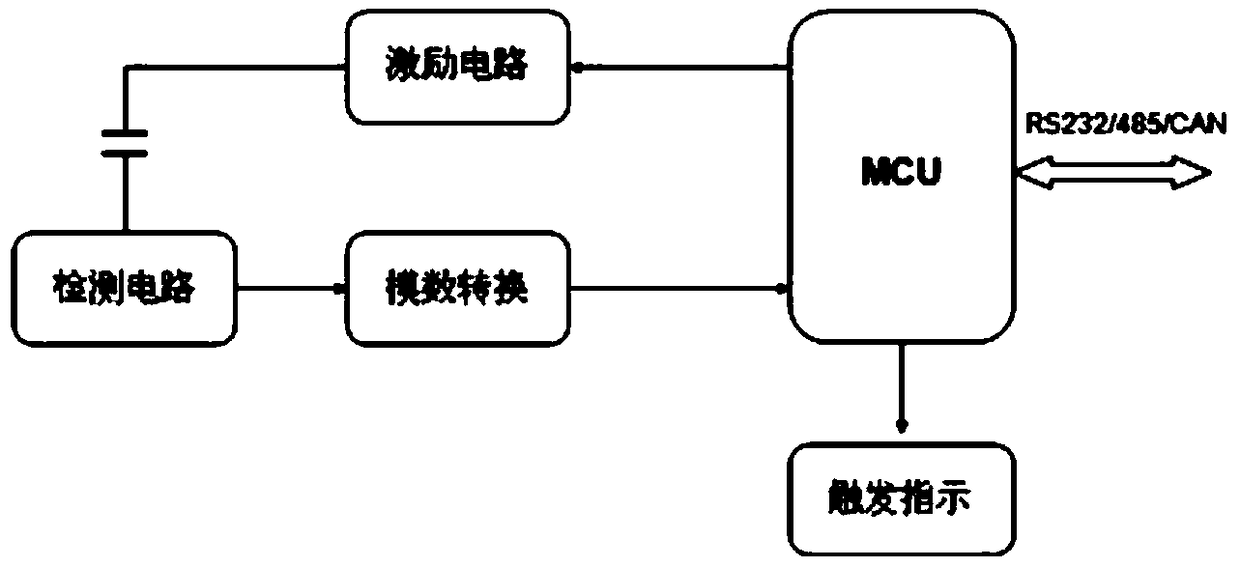

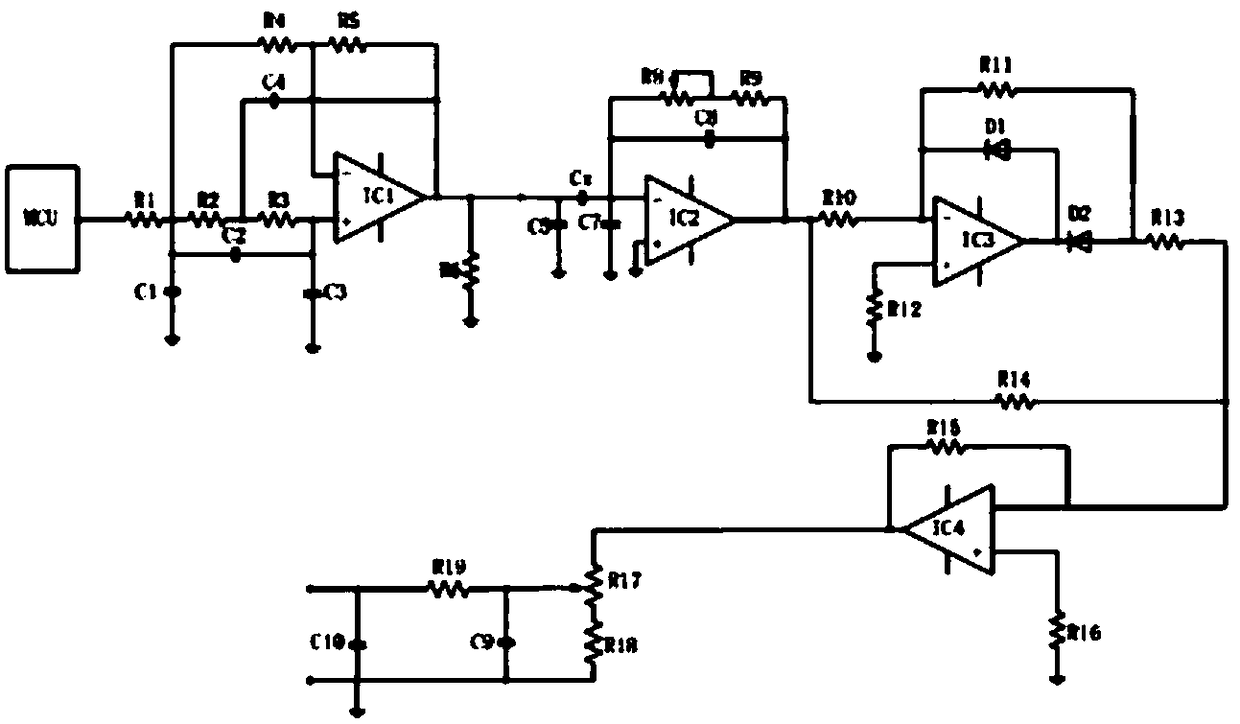

[0058] Such as figure 1 As shown, the programmable universal capacitive liquid level sensor controller of the present invention mainly includes an excitation circuit, a detection circuit, a digital-to-analog conversion module, a digital processing module, a communication interface and a command processing module. The excitation circuit is used to excite the object to be detected so that it produces a signal representing its characteristics. The detection circuit converts the signal representing the characteristics of the detection object into a signal that is easy to process and record. The analog-to-digital conversion module converts the analog signal output by the detection circuit into a digital signal and sends it to the microprocessor module for processing. The digital processing module processes the signal to obtain the detection result, and transmits it to the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com