Quick design optimization method of power assembly suspension decoupling

A powertrain and optimization method technology, applied in computing, special data processing applications, instruments, etc., can solve the problems of not being able to support the mixed optimization design of the mounting position at the same time, long analysis time, and high time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

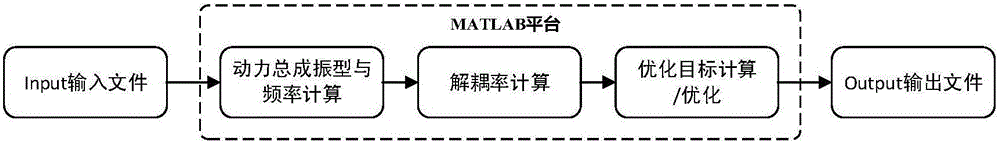

Method used

Image

Examples

Embodiment Construction

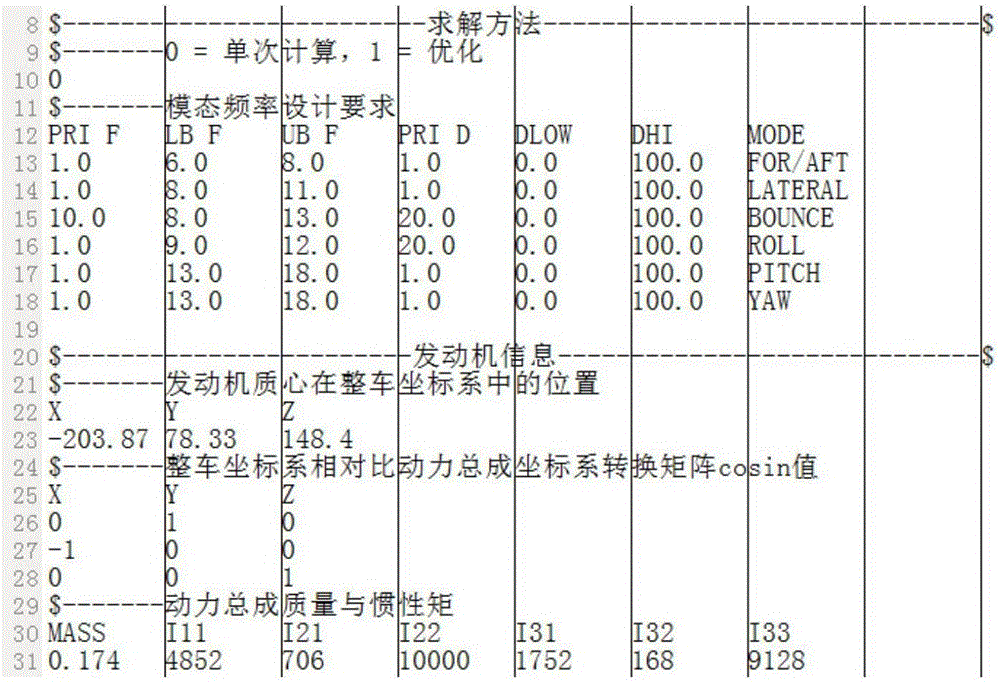

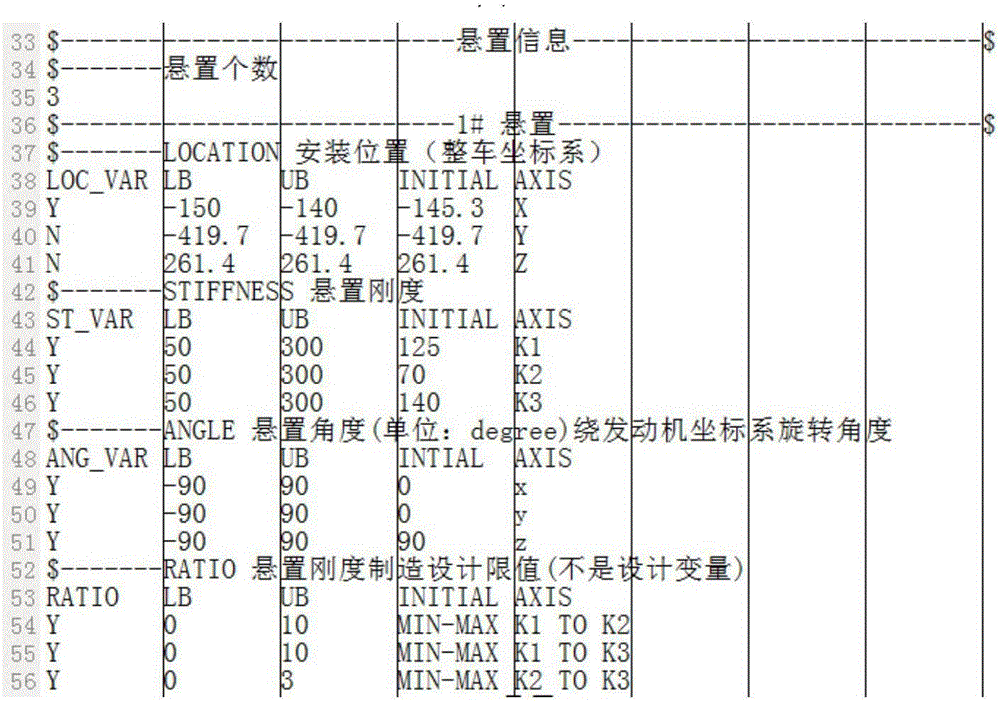

[0092] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below through an example of optimal design of a powertrain of a certain vehicle type, and the comprehensive performance of the present invention will be verified.

[0093] In order to better illustrate this method, the coordinate system used in the method is described:

[0094] Vehicle coordinate system G-XYZ: the origin is located at the center of mass of the vehicle at rest, the positive direction of the Z-axis is vertically upward, the positive direction of the X-axis points to the rear of the vehicle, and the Y-axis is determined according to the right-hand rule.

[0095] Powertrain coordinate system g-xyz: the origin of the coordinates is at the center of mass of the powertrain, the x-axis is parallel to the direction of the engine crankshaft, and the positive direction points to the engine side; the z-axis is perpendicular to the flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com