Machine vision-based ship hull six-degree-of-freedom measurement method

A technology of machine vision and measurement methods, applied in measurement devices, instruments, image data processing, etc., can solve the problems of seldom application, insufficient precision, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

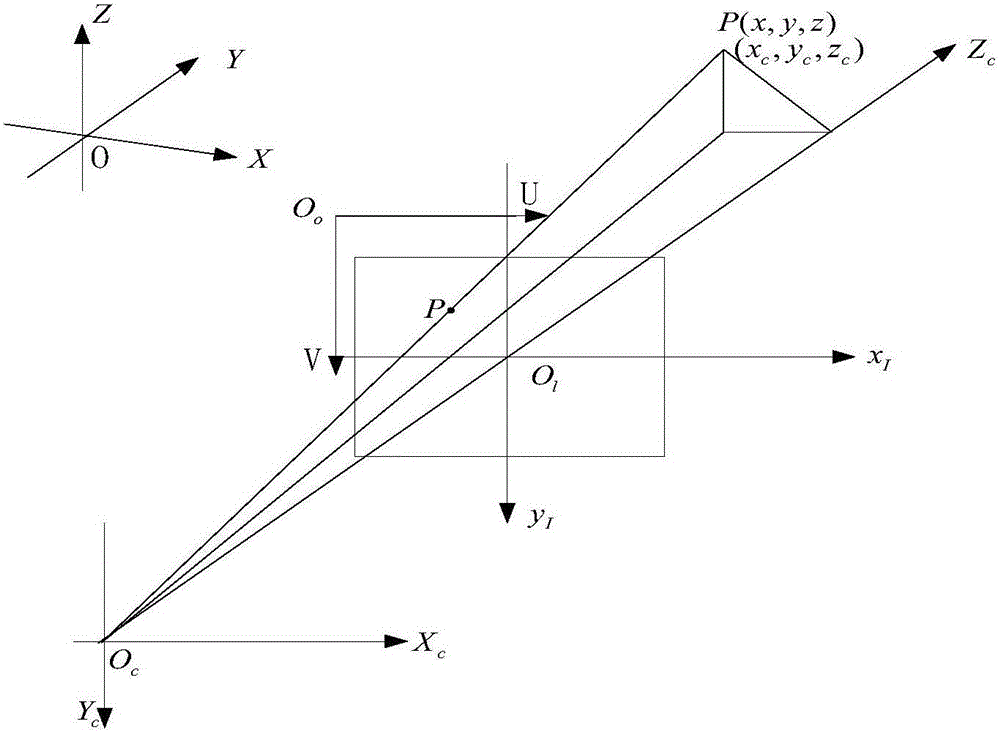

[0048]The present invention will be described in further detail below in conjunction with the accompanying drawings.

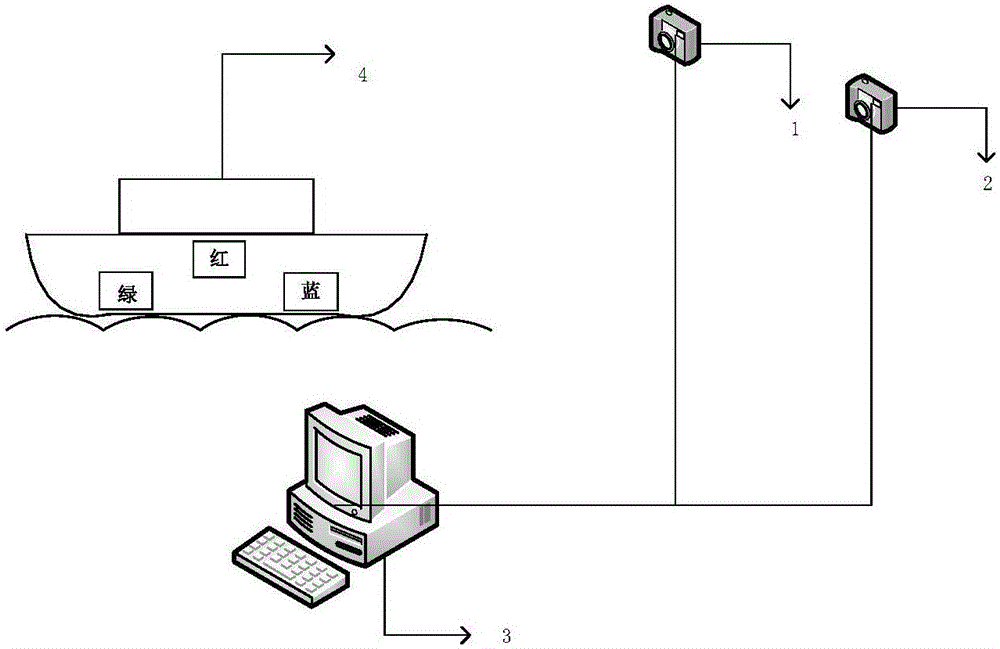

[0049] The problem solved by the technology of the present invention is: in order to overcome the shortcomings of the existing six-degree-of-freedom measuring equipment of the ship hull, which are huge, complicated to install, and have low precision, the present invention provides a non-contact real-time six-degree-of-freedom measuring method for the ship hull, which can not only accurately measure The value of the six degrees of freedom of the hull, and because of its non-contact characteristics, the measurement method is more convenient and effective.

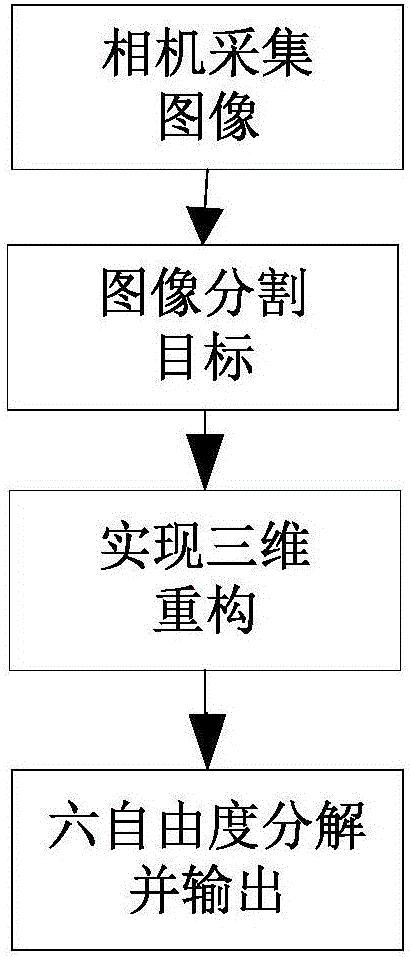

[0050] The technical solution adopted by the present invention to solve its technical problems is: figure 1 The shown method flowchart concisely introduces the whole measurement process.

[0051] Step 1: Two cameras placed in different positions are connected to the image acquisition card in the computer thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com