High-voltage high-frequency transformer with single-phase high-power special insulation structure

A special insulation, high-voltage and high-frequency technology, applied in the direction of fixed transformer or mutual inductance, transformer/inductor magnetic core, transformer/inductor components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the example shown in accompanying drawing:

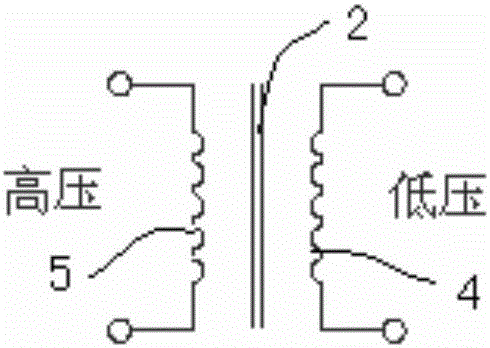

[0024] see figure 1 , shown in the figure is an electrical schematic diagram of a high-voltage and high-frequency transformer with a single-phase high-power special insulation structure. The high-voltage outer coil 5 and the low-voltage inner coil 4 are each arranged in one layer.

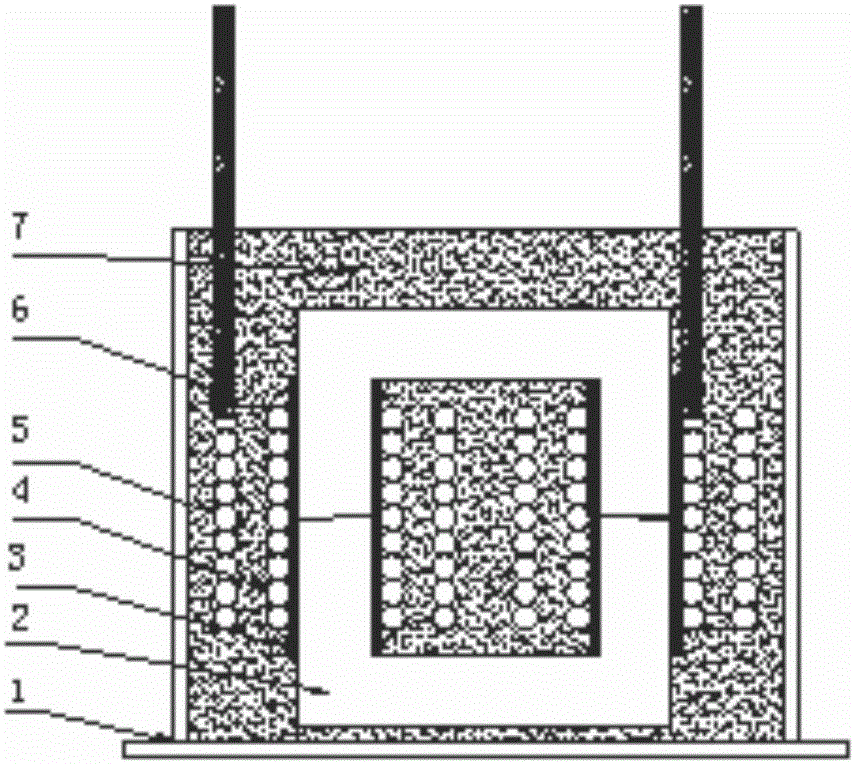

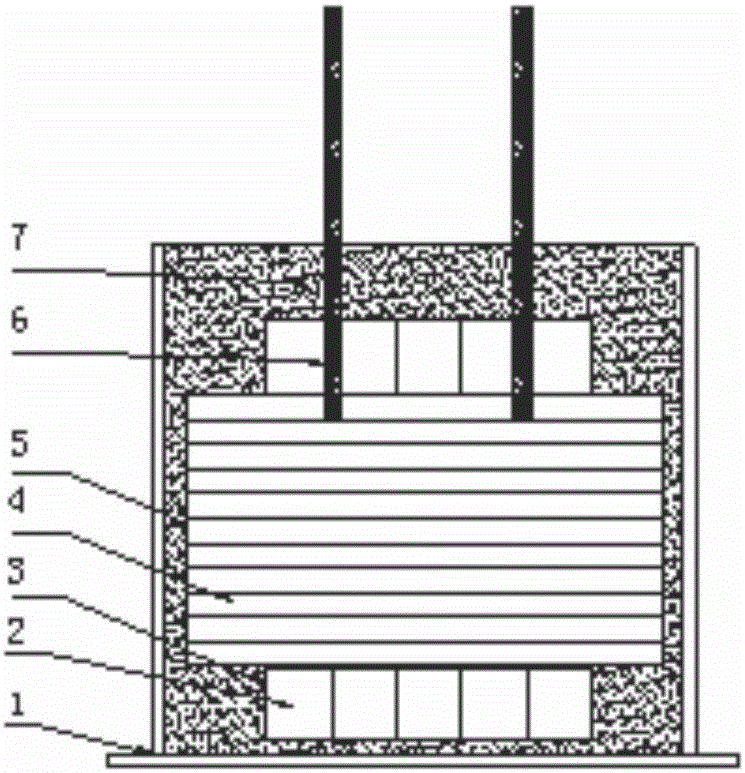

[0025] see figure 2 , image 3 , Figure 4 , a high-voltage and high-frequency transformer with single-phase high-power special insulation structure shown in the figure, including casing 1, iron core 2, iron core insulation layer 3, low-voltage inner coil 4, high-voltage outer coil 5, lead wire 6, epoxy Resin insulating layer 7. The shell 1 is made of aluminum, and the lead 6 is a high-voltage resistant silicon rubber wire with an insulation layer thickness greater than 3mm.

[0026] The specific preparation method is: the iron core 2 is made of the iron core insulatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com