Flywheel rotating speed control device and method based on linear Hall sensors

A hall sensor, linear hall technology, applied in the direction of controlling electromechanical transmission, control system, control generator, etc., can solve the problem of insufficient efficiency, and achieve the requirements of simple structure, cost saving, and reduction of storage and computing resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present invention will be further described in conjunction with the drawings and embodiments.

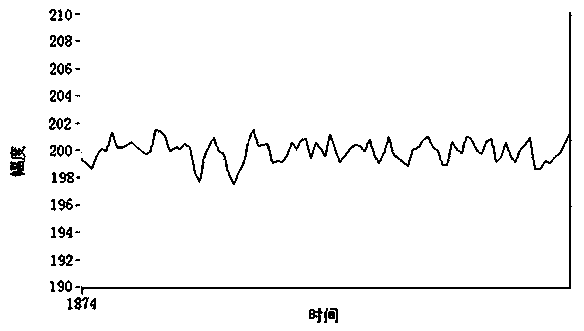

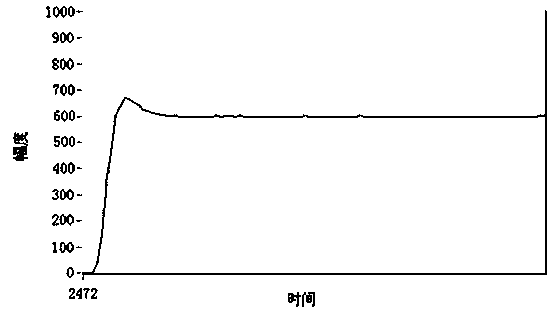

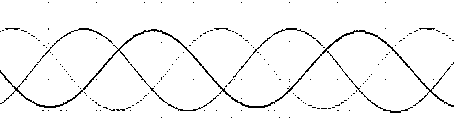

[0028] Such as figure 1 As shown, the flywheel speed control device based on the linear Hall sensor provided by the present invention includes: a first linear Hall sensor 1, a second linear Hall sensor 2, a third linear Hall sensor 3 and a DC brushless motor 13 (see image 3 ); three linear Hall sensors space 120 Symmetrically installed on the stator of the DC brushless motor, the flywheel is the rotor of the DC brushless motor; the DC brushless motor has three-phase outputs of A, B, and C, and the three linear Hall sensors are respectively proportional to the three output counter electromotive force. 30 electrical angle. exist figure 1 In the illustrated embodiment, a DC brushless motor with 7 pairs of poles is used, and in other embodiments, a DC brushless motor can be selected according to application requirements. figure 1 Among them, A+ is the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com