Self-service bee divider and realization method thereof

A realization method and a technology of a bee sorting device, which are applied in beehives, beekeeping, applications, etc., can solve the problems of being unable to find the seal king, unable to take it out, and low efficiency, and achieve simple and practical bee sorting, easy connection and fixation, and economic benefits high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

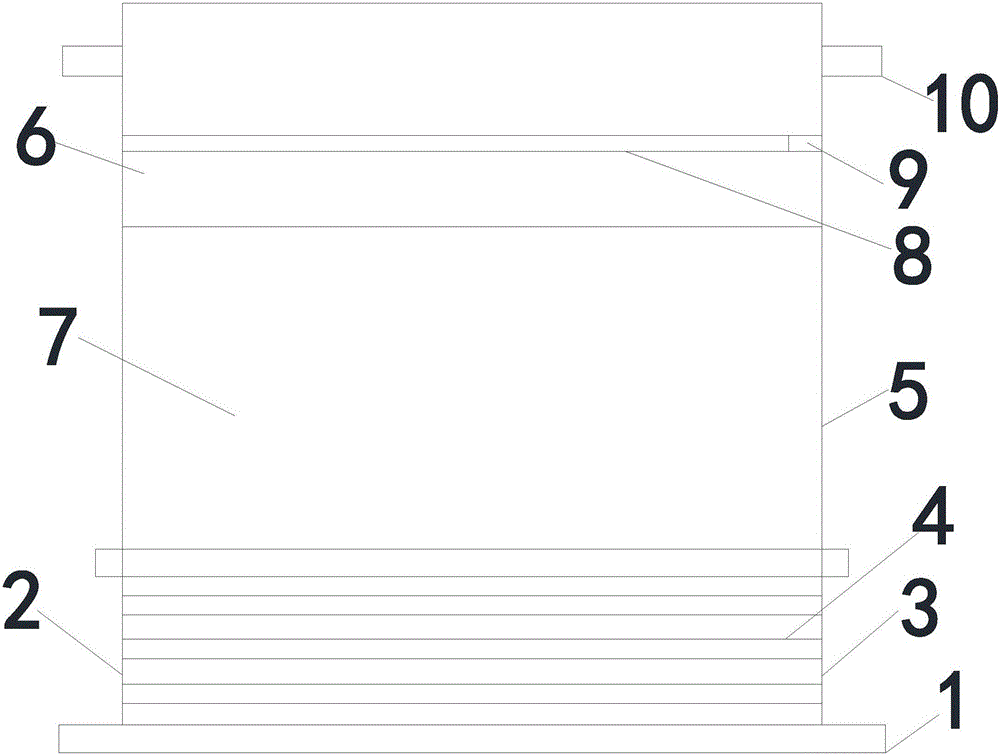

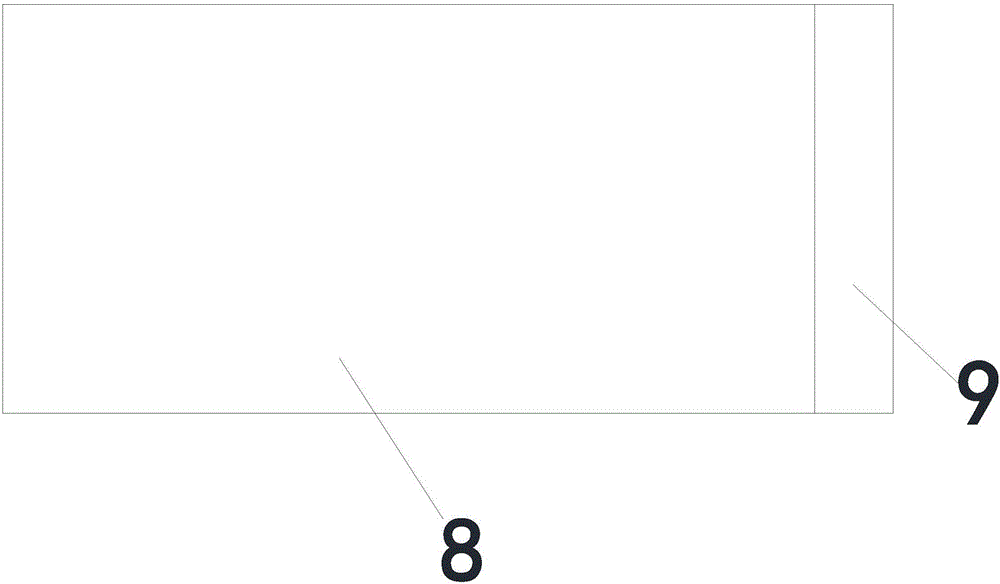

[0037] Such as Figure 1~2 As shown, a self-service bee sorting device includes a bottom plate, the bottom plate is connected with the left plate of the beehive and the right plate of the beehive, the front end and the rear end of the beehive are empty, and the front end of the beehive is provided with a number of stays. The bottom plate is the runway; the beehive is connected to the bee collector through the connecting rod, the heat dissipation yarn is arranged between the beehive and the bee collector, the bottom of the heat dissipation yarn at the rear end of the beehive is connected to the beehive body, and the bee collector is equipped with The bee-distributing connection part, the side of the bee-distributing connection part is the queen bee channel.

[0038] In this embodiment, fixing bolts are arranged on the bottom plate; the king rods are uniformly arranged horizontally; the distance between adjacent king rods is 2 mm.

[0039] In the present embodiment, the base pl...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that: the distance between the adjacent king rods in this embodiment is 6mm; the booster runway and the horizontal plane are at an angle of 35°; The width of the queen bee channel is 15mm; a circular connection part (not shown) connected with the barrel-shaped box is provided in the bee collector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com