Electrostatic dust collector burr piece discharge cathode line

A technology of electrostatic precipitator and thorn sheet, which is applied in the direction of electrode structure, electrostatic separation, electrostatic effect separation, etc., to achieve the effect of reducing the corona dead zone, solving the secondary flying, and reducing the failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

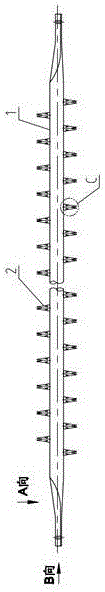

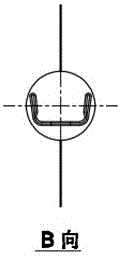

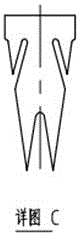

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention adopts the high-frequency welded pipe pole line 1 as a rigid metal pipe, and its two ends are pressed into a U-shaped groove with a special flattening die, and are punched with mounting holes, and one end of the high-frequency welded pipe pole line 1 is bolted It is connected with the top frame, and the other end is connected with the bottom frame as a whole; the cathode line burr sheet is made of 0.7mm steel plate, and 4 sharp-angle burr sheets are welded at intervals of 100mm on both sides of the high-frequency welded tube pole line 1. .

[0024] Such as Figure 4 and Figure 5 As shown, on the pole line 1 of the high-frequency welded pipe, 4 sharp-edged burrs 2 are welded by a CO2 welding machine, and the welding operation is required to meet the technical requirements. point, contact the opposite side and weld one point to complete the product; 4 sharp-edged burr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com