Recycling molding device of building waste

A technology for forming equipment and construction waste, applied in the field of construction waste recycling and forming equipment, can solve the problems of waste of resources, prolonging the progress of the construction period, poor environment, etc., and achieve the effects of reducing construction costs, improving utilization, and simplifying recycling and processing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

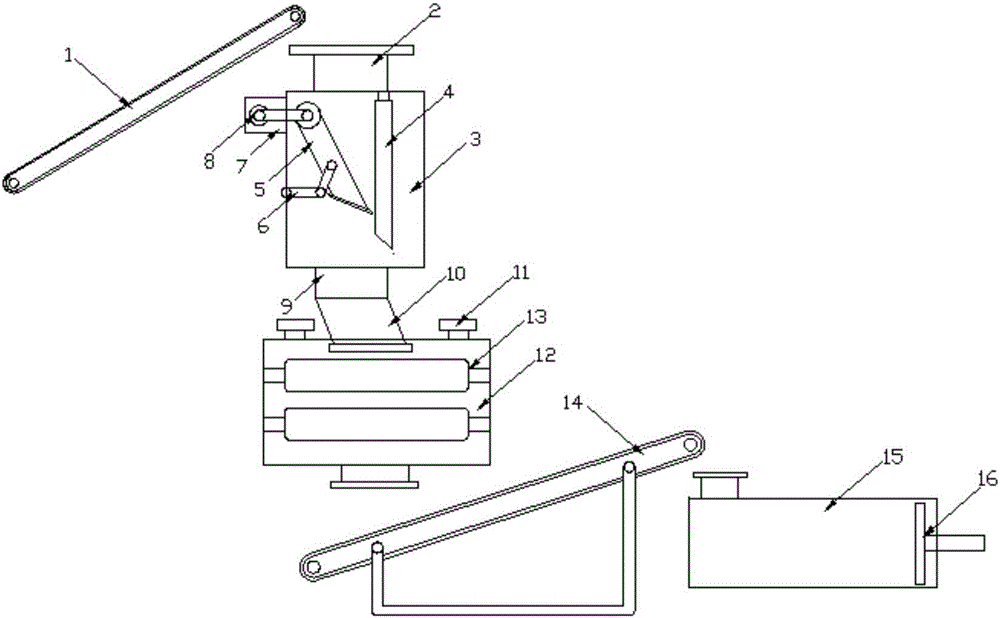

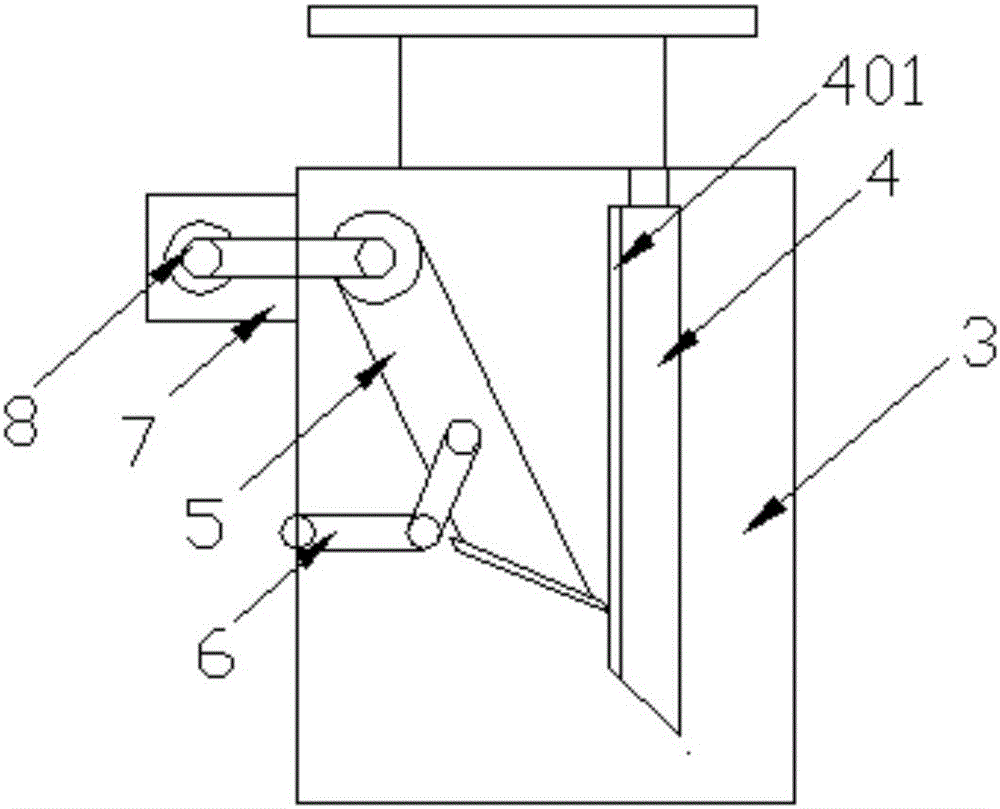

[0017] Such as Figure 1-2 As shown, a kind of construction waste recycling molding equipment includes a crushing bin 3 and a crushing bin feed port 2 arranged on the top of the crushing bin 3, the top of the crushing bin feed port 2 is provided with a first conveyor belt 1, and the crushing bin 3 A fixed crushing plate 4 is arranged vertically inside, and an extruding plate 5 is arranged on one side of the fixed crushing plate 4. One end of the extruding plate 5 is attached to the fixed crushing plate 4, and the other end of the extruding plate 5 is fixed with a transmission wheel 8. The transmission end of the wheel 8 is connected with a motor 7, the motor 7 is fixed on the side of the crushing bin 3, the bottom of the crushing bin 3 is fixed with a discharge bin 10, the bottom of the discharge bin 10 is fixed in the crushing bin 12, and the interior of the crushing bin 12 is set There is a crushing shaft 13, the top of the crushing bin 12 is provided with a water injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com