A device for suppressing the oxidation rate of rolls and its application method

A technology of oxidation rate and roll, applied in the rolling mill control device, keeping the rolling equipment in an effective state, metal rolling and other directions, can solve the problems of the interference effect of the rolling oil, reduce the scale of the roll system, improve the uniform density, The effect of too fast a cost-effective production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

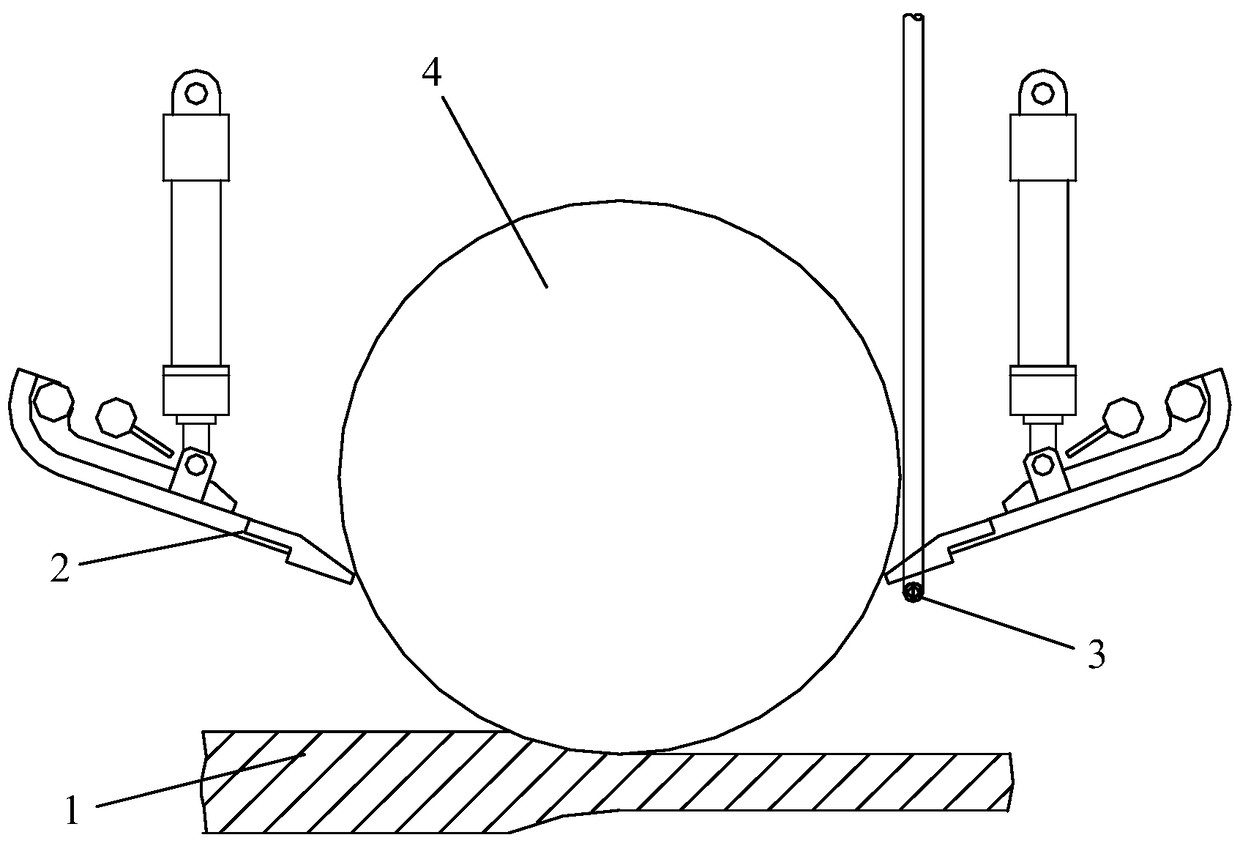

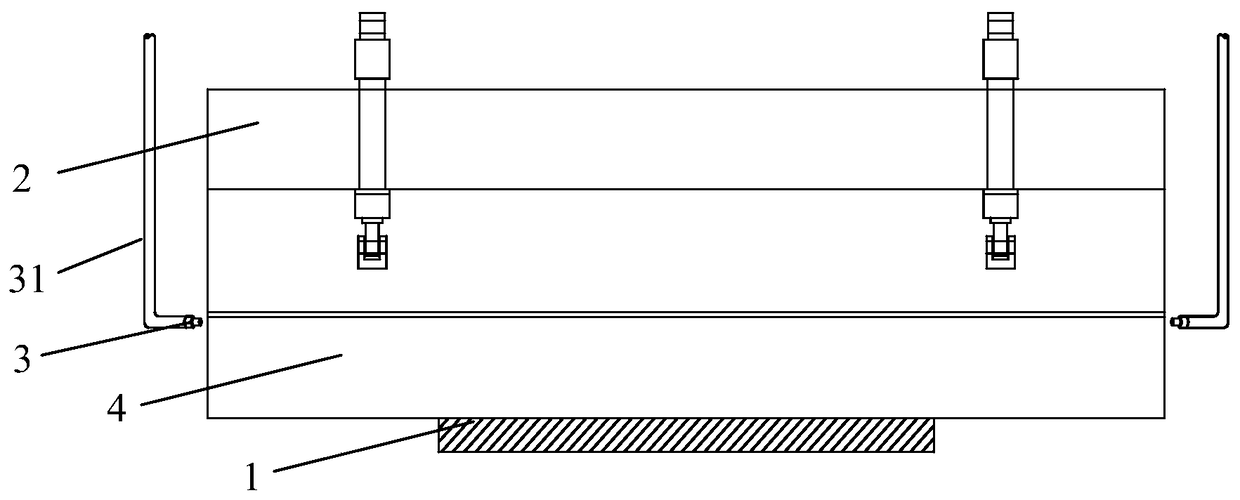

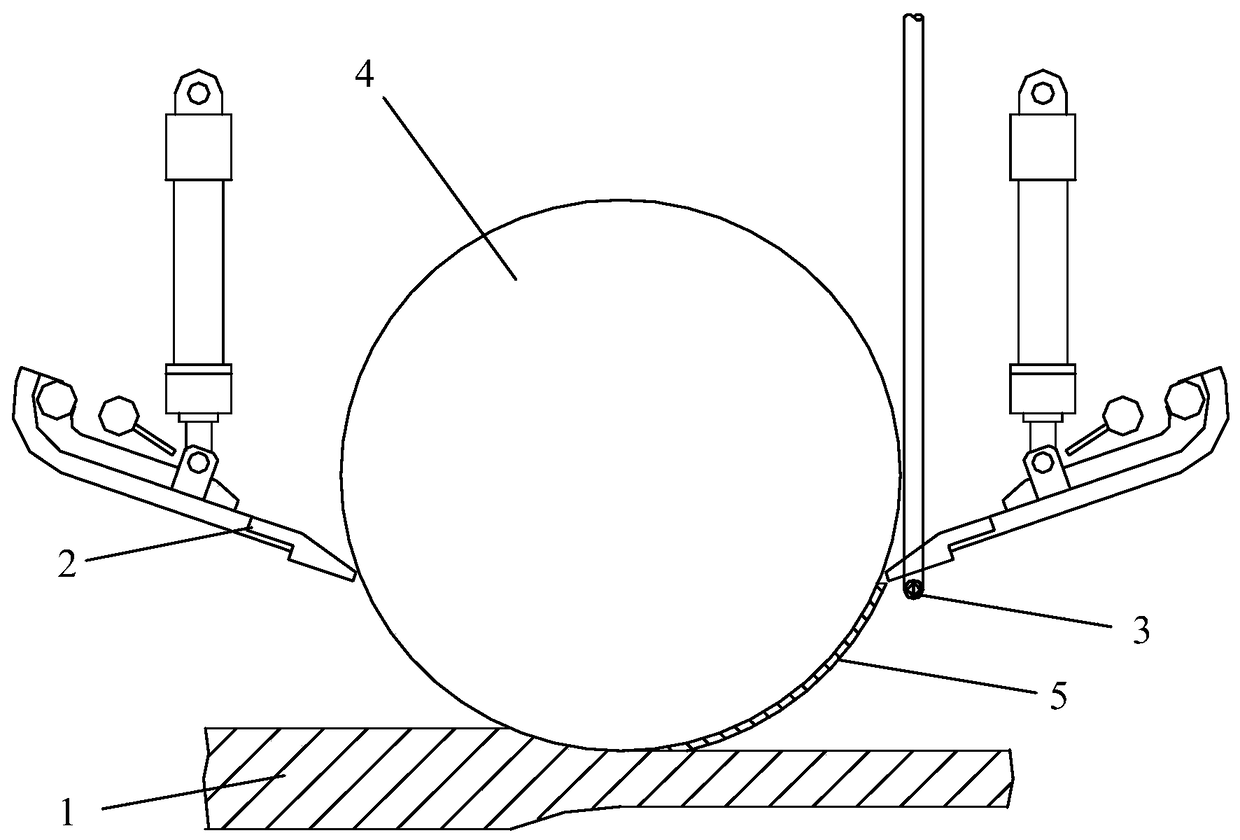

[0047] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

[0048] The present invention mainly relates to the protection technology of inert gas and the basic automation level control L1 in the above-mentioned computer-controlled strip rolling process (mainly completing the sequence control, position control, speed control, etc. of the equipment, receiving and executing from the process control level The setting value of L2) and the automatic control technology associated with the process control level L2 (mainly performing the rolling schedule formulation and optimization function based on the mathematical model, and sending the set calculation value to L1).

[0049] First of all, based on the different materials of the strip steel grades to be rolled and the characteristics of different oxidation rates on the surface of the rolls, different opening modes are selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com