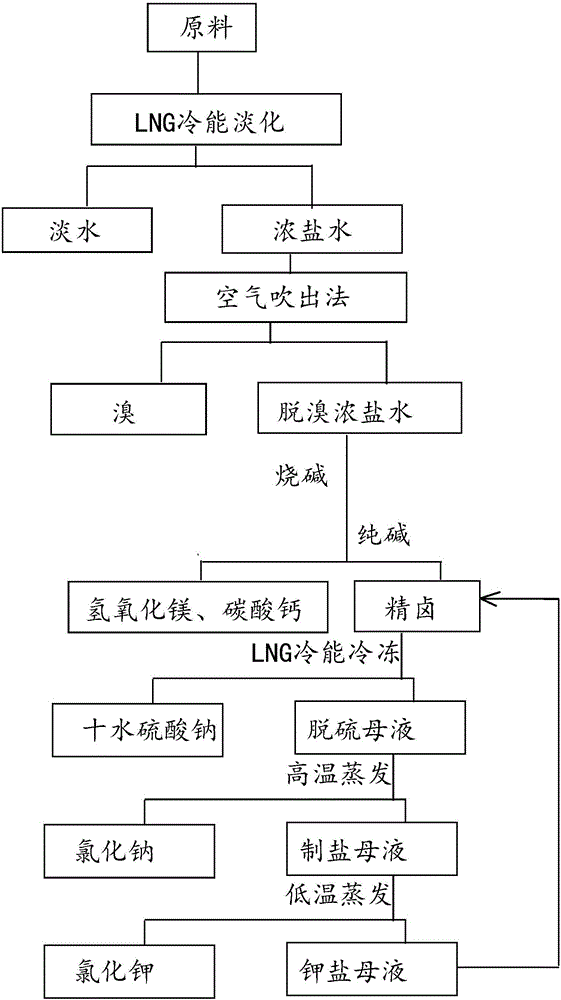

LNG cold energy seawater desalination and concentrated saltwater comprehensive utilization technology

A concentrated brine and cold energy technology, which can be used in chilled water/sewage treatment, seawater treatment, alkali metal compounds, etc., can solve problems such as poor economy and adaptability, and achieve increased product added value, low production cost and energy consumption, and high technological Reasonable effect of process and cold energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: take 1000m 3 Seawater (NaCl29.30g / l, KCl0.72g / l, NaBr0.14g / l, MgSO 4 2.15g / l, CaSO 4 1.53g / l, MgCl 2 3.28g / l) as raw material, use LNG cold energy freezing (-30℃) to desalinate seawater to produce fresh water and 117.2m 3 Concentrated brine (NaCl249.99g / l, KCl6.15g / l, NaBr1.19g / l, MgSO 4 18.35g / l, CaSO 4 0.61g / l, MgCl 2 27.99g / l); the 117.2m 3 Bromine (Br 2 ) and 117.2m 3 Debrominated brine (NaCl249.99g / l, KCl6.15g / l, NaBr0.01-0.02g / l, MgSO 4 18.35g / l, CaSO 4 0.61g / l, MgCl 2 27.99g / l); to 117.2m 3 Add caustic soda and soda ash to debrominated concentrated brine to produce 2.85 tons of magnesium hydroxide, 0.052 tons of calcium carbonate and 117.2m 3 Refined halogen (NaCl249.99g / l, KCl6.15g / l, NaBr0.01-0.02g / l, NaCl 2 SO 4 21.71g / l, Ca 2+ 0.030g / l, Mg 2+ 0.020g / l); Use LNG cold energy to freeze (-24°C) 117.2m 3 Refined brine produced 5.32 tons of sodium sulfate decahydrate and 114.2m 3 Desulfurization mother liquor (NaCl256.56g / l, KCl6.31g...

Embodiment 2

[0033] Embodiment 2: take 1000m 3 Seawater (NaCl29.30g / l, KCl0.72g / l, NaBr0.14g / l, MgSO 4 2.15g / l, CaSO 4 1.53g / l, MgCl 2 3.28g / l) as raw material, use LNG cold energy freezing (-20 ℃) to desalinate seawater to produce fresh water and 117.2m 3 Concentrated brine (NaCl249.99g / l, KCl6.15g / l, NaBr1.19g / l, MgSO 4 18.35g / l, CaSO 4 0.61g / l, MgCl 2 27.99g / l); the 117.2m 3 Bromine (Br 2 ) and 117.2m 3 Debrominated brine (NaCl249.99g / l, KCl6.15g / l, NaBr0.01-0.02g / l, MgSO 4 18.35g / l, CaSO 4 0.61g / l, MgCl 2 27.99g / l); to 117.2m 3 Add caustic soda and soda ash to debrominated concentrated brine to produce 2.85 tons of magnesium hydroxide, 0.052 tons of calcium carbonate and 117.2m 3 Refined halogen (NaCl249.99g / l, KCl6.15g / l, NaBr0.01-0.02g / l, NaCl 2 SO 4 21.71g / l, Ca 2+ 0.030g / l, Mg 2+ 0.020g / l); Use LNG cold energy to freeze (-21.5°C) 117.2m 3 Refined brine produced 5.32 tons of sodium sulfate decahydrate and 114.2m 3 Desulfurization mother liquor (NaCl256.56g / l, KCl...

Embodiment 3

[0034] Embodiment 3: take 1000m 3 Seawater (NaCl29.30g / l, KCl0.72g / l, NaBr0.14g / l, MgSO 4 2.15g / l, CaSO 4 1.53g / l, MgCl 2 3.28g / l) as raw material, using LNG cold energy freezing (-5 ℃) for seawater desalination to produce fresh water and 117.2m 3 Concentrated brine (NaCl249.99g / l, KCl6.15g / l, NaBr1.19g / l, MgSO 4 18.35g / l, CaSO 4 0.61g / l, MgCl 2 27.99g / l); the 117.2m 3 Bromine (Br 2 ) and 117.2m 3 Debrominated brine (NaCl249.99g / l, KCl6.15g / l, NaBr0.01-0.02g / l, MgSO 4 18.35g / l, CaSO 4 0.61g / l, MgCl 2 27.99g / l); to 117.2m 3 Add caustic soda and soda ash to debrominated concentrated brine to produce 2.85 tons of magnesium hydroxide, 0.052 tons of calcium carbonate and 117.2m 3 Refined halogen (NaCl249.99g / l, KCl6.15g / l, NaBr0.01-0.02g / l, NaCl 2 SO 4 21.71g / l, Ca 2+ 0.030g / l, Mg 2+ 0.020g / l); Use LNG cold energy to freeze (-21.5°C) 117.2m 3 Refined brine produced 5.32 tons of sodium sulfate decahydrate and 114.2m 3 Desulfurization mother liquor (NaCl256.56g / l, K...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap