Oil-water separating device, and oil sludge separating apparatus including same

A technology of oil-water separation device and heat exchange device, which is applied in dehydration/drying/concentrated sludge treatment, grease/oily substance/float removal device, liquid separation, etc., can solve resource waste, low oil and gas recovery efficiency, and environmental pollution and other problems, to avoid sucking back, improve condensation efficiency, and improve recovery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

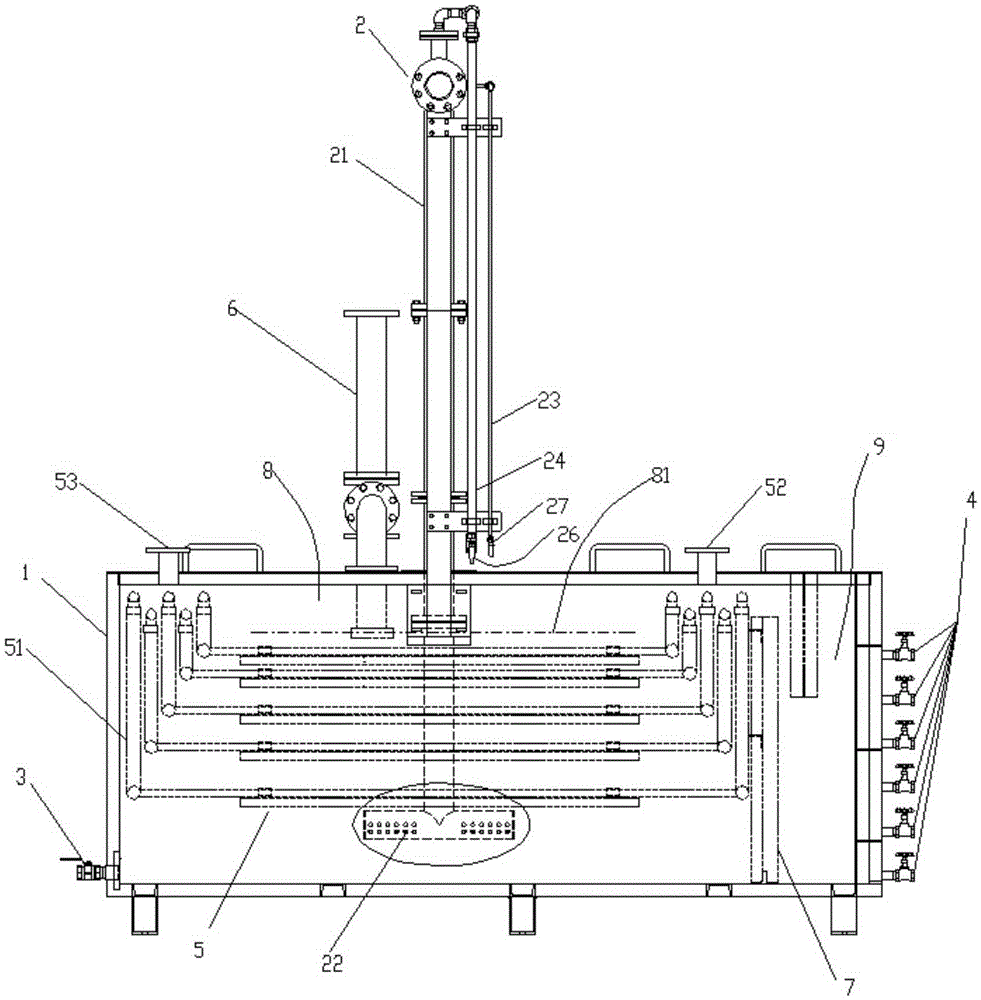

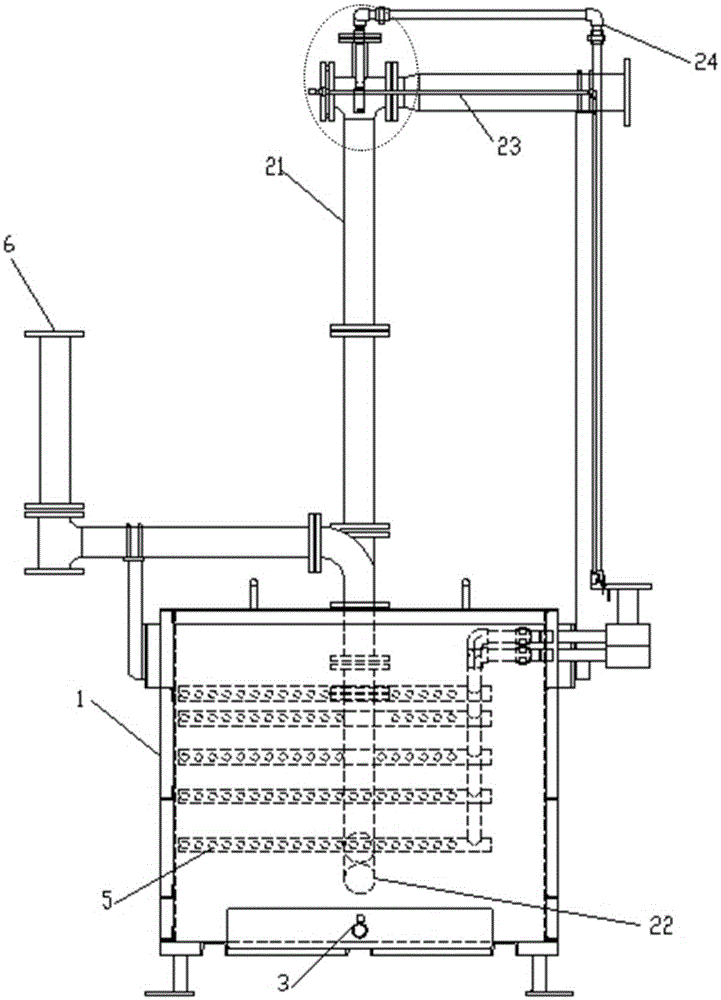

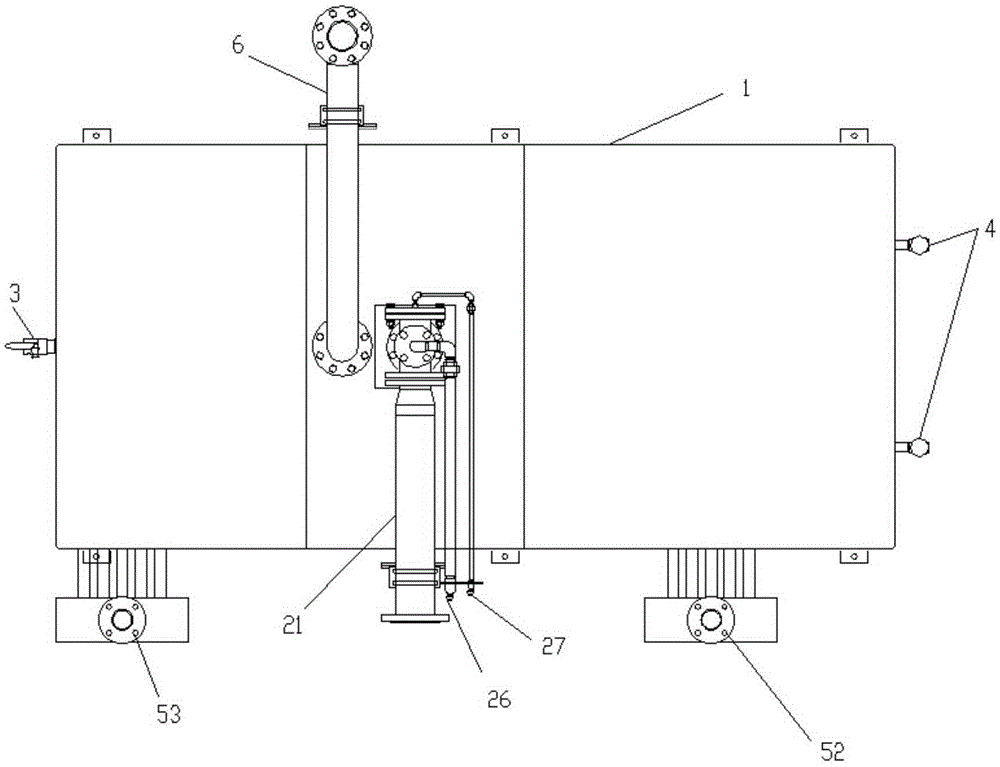

[0036] combine figure 1 and Figure 5 As shown, an oil-water separation device includes a housing 1 for holding liquid oil and water, an oil inlet device 2 arranged on the housing 1, a drain 3 located on one side of the bottom of the housing 1 and a water outlet located on the other side. A plurality of oil outlets 4 on the side, and a heat exchange device 5 arranged in the housing 1 for cooling the liquid contained in the housing 1, the heat exchange device 5 includes a multi-layer heat exchange tube 51, and the heat exchange tube 51 is connected to Condensed water is used to reduce the temperature in the casing 1 . The oil inlet device 2 includes an oil inlet pipeline 21 connected to the housing 1 and a cooling device arranged in the oil inlet pipeline 21 for condensing high-temperature oil-water mixture, the cooling device is preferably a spray cooling device, Cool the high-temperature oil-water mixture by spraying condensed water. One end of the oil inlet pipe 21 inside...

Embodiment 2

[0044] Such as Figure 6 As shown, the difference between the present embodiment and the first embodiment is that: the middle part of the short pipe 22 is rotatably connected with the oil inlet pipe 21 and communicated with each other, and the two ends of the short pipe are closed. The short pipe 22 is rotatably connected to the bottom of the oil inlet pipeline 21, and the two are connected by a rotary joint 28. The nozzles are arranged on the side wall of the short pipe 22 and distributed on different sides of the short pipe 22, and to further The axis of the oil pipeline 21 is centered and symmetrically arranged. After the high-temperature gas is ejected from the nozzle, it generates a reaction force that pushes the short pipe 22 to rotate. The rotation of the short pipe 22 makes the bubbles ejected from the nozzle more uniform and larger. The dispersion area is in contact with the condensed water in the housing 1 to achieve a better condensation effect.

[0045] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com