Energy-saving environment-friendly self-cleaning chimney

An energy-saving, environment-friendly, self-cleaning technology, applied in the field of chimneys, can solve problems such as easy attachment to the inner wall of the chimney, affect the normal discharge of the chimney, and inconvenience users, so as to improve the condensation effect, improve the practical effect, and reduce energy loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

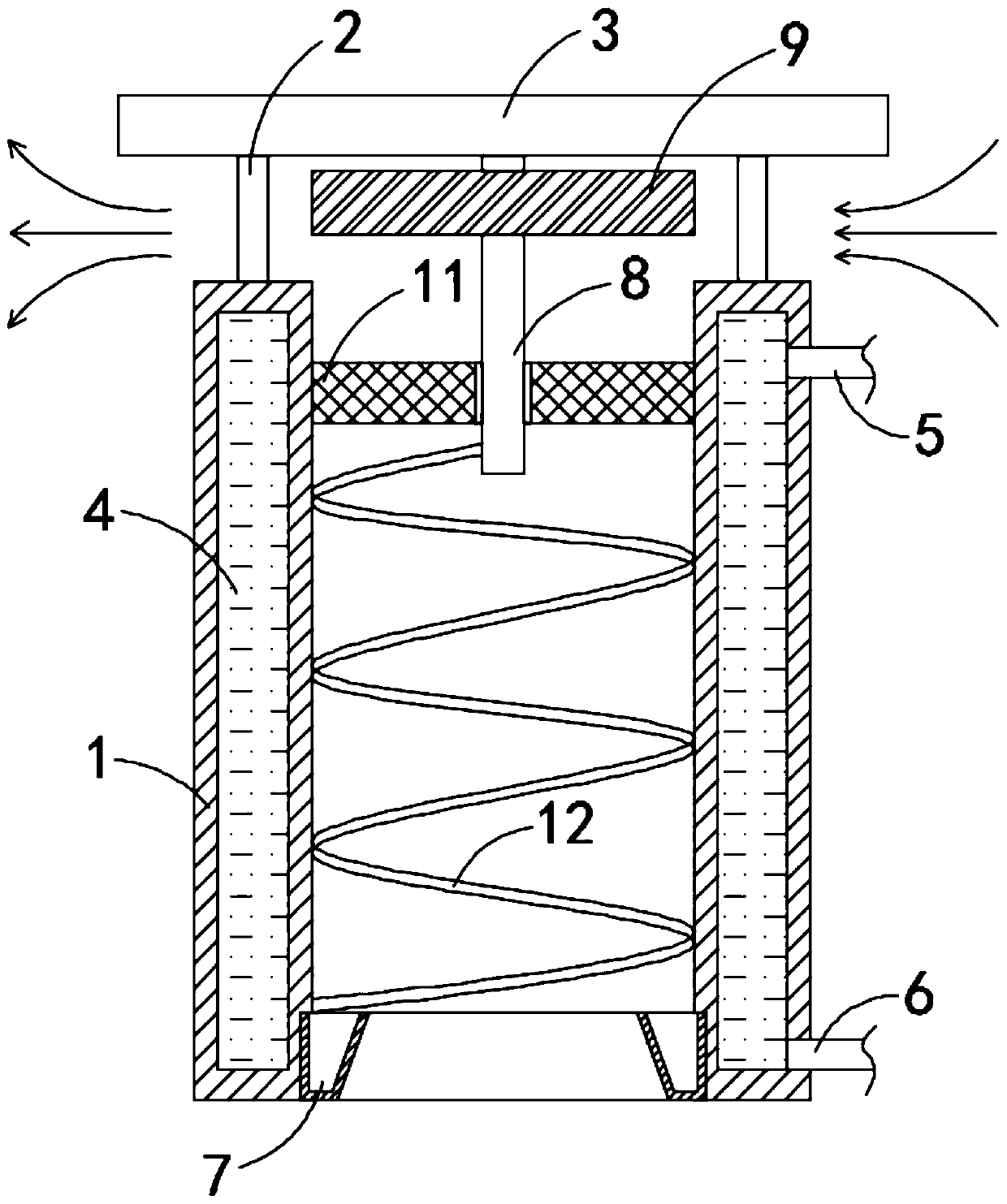

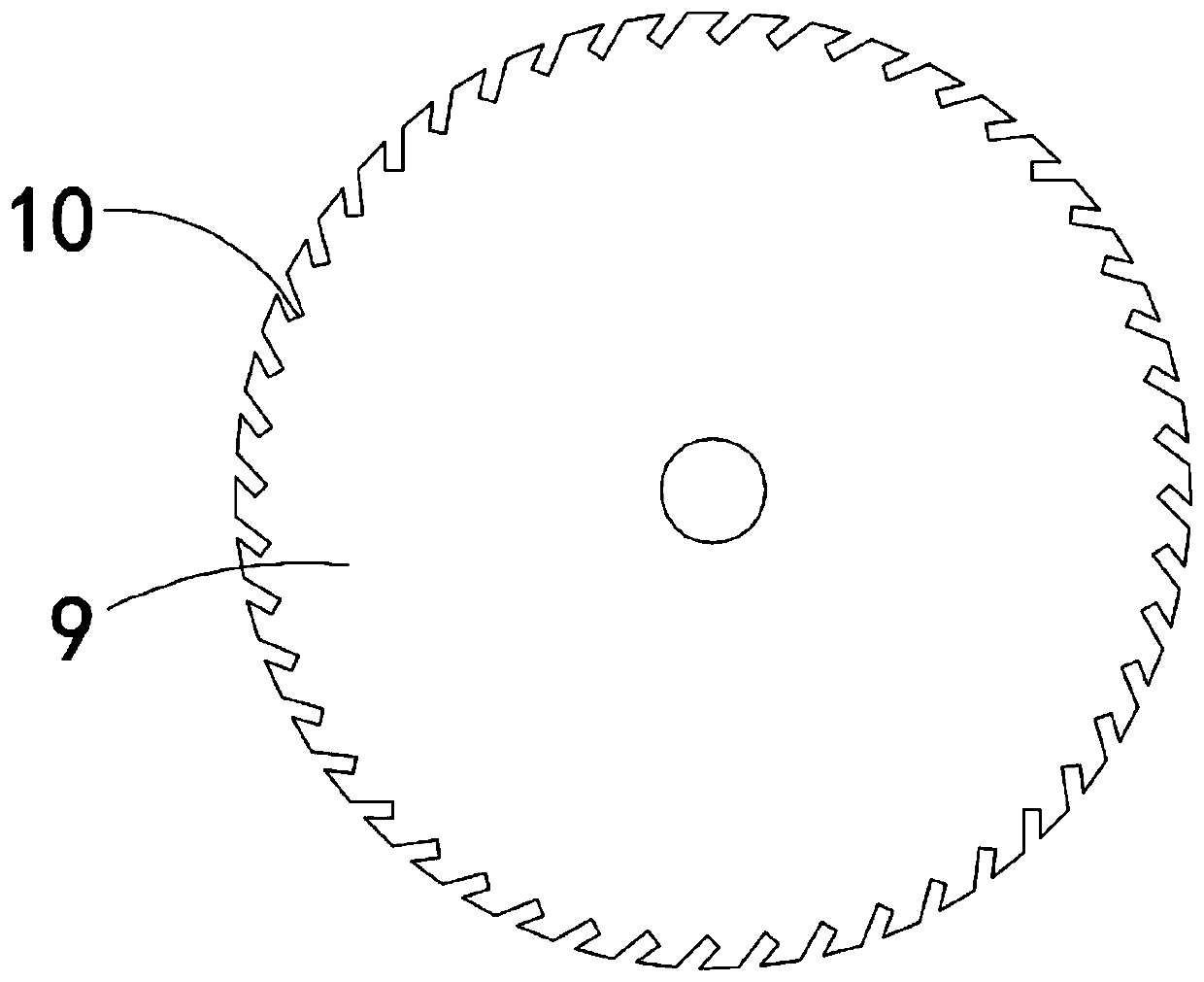

[0018] Such as Figure 1-2 As shown, an energy-saving and environment-friendly self-cleaning chimney includes a chimney body 1, the upper end of the chimney body 1 is fixedly connected with a rain shield 3 through a plurality of connecting rods 2, and the rain shield 3 is used to prevent rainwater or other sundries from entering the chimney Inside, it can be made of stainless steel. The side wall of the chimney body 1 is provided with a water storage chamber 4. The water storage chamber 4 is annular. The water storage chamber 4 communicates with the outside through the water inlet pipe 5 and the drain pipe 6. The pipe 6 is used to replace the water in the water storage chamber 4. On the one hand, the water temperature in the water storage chamber 4 can be kept within a suitable temperature range, so as to improve the cooling effect of the chimney body 1 on the grease particles; The water in the water chamber 4 is taken out and utilized to reduce the waste of resources. The inn...

Embodiment 2

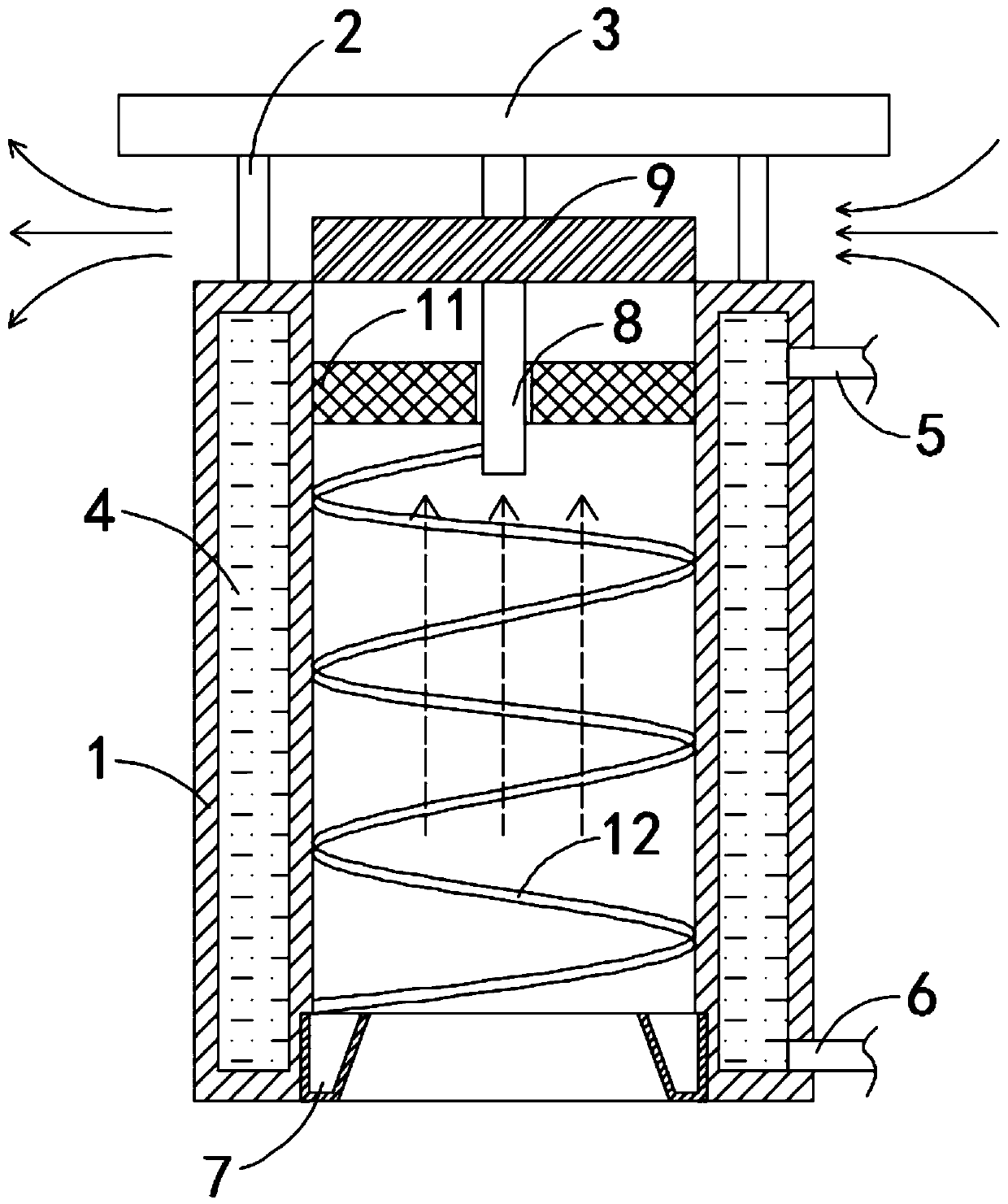

[0021] Such as Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that the lower end of the runner 9 is flush with the upper end of the chimney body 1, the runner 9 includes a rotating cover 13 and a rotating block 14, and the outer wall of the rotating block 14 is fixed A plurality of fan blades 15 are connected, the fan blades 15 are fixedly connected to the inner side wall of the rotating cover 13 , the rotating block 14 is fixedly connected coaxially with the rotating shaft 8 , and the flow guide groove 10 is arranged on the outer side wall of the rotating cover 13 .

[0022] In the present embodiment, when flue gas is discharged from chimney body 1 (as image 3 Shown by the dotted arrow in the middle), it will act on the fan blade 15 to promote the rotation of the runner 9, thereby improving the cleaning effect on the chimney body 1, and, because the smoke is directly discharged from the runner 9, under the action of the external airflow Nex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com