Design method of support parameters for short-distance coal roadway under goaf in coal mine

A design method and support parameter technology, applied in the direction of calculation, data processing application, electrical digital data processing, etc., can solve problems that affect normal production, it is difficult to ensure the integrity of the roadway, damage, etc., to avoid mine pressure and prevent loosening Falling, improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

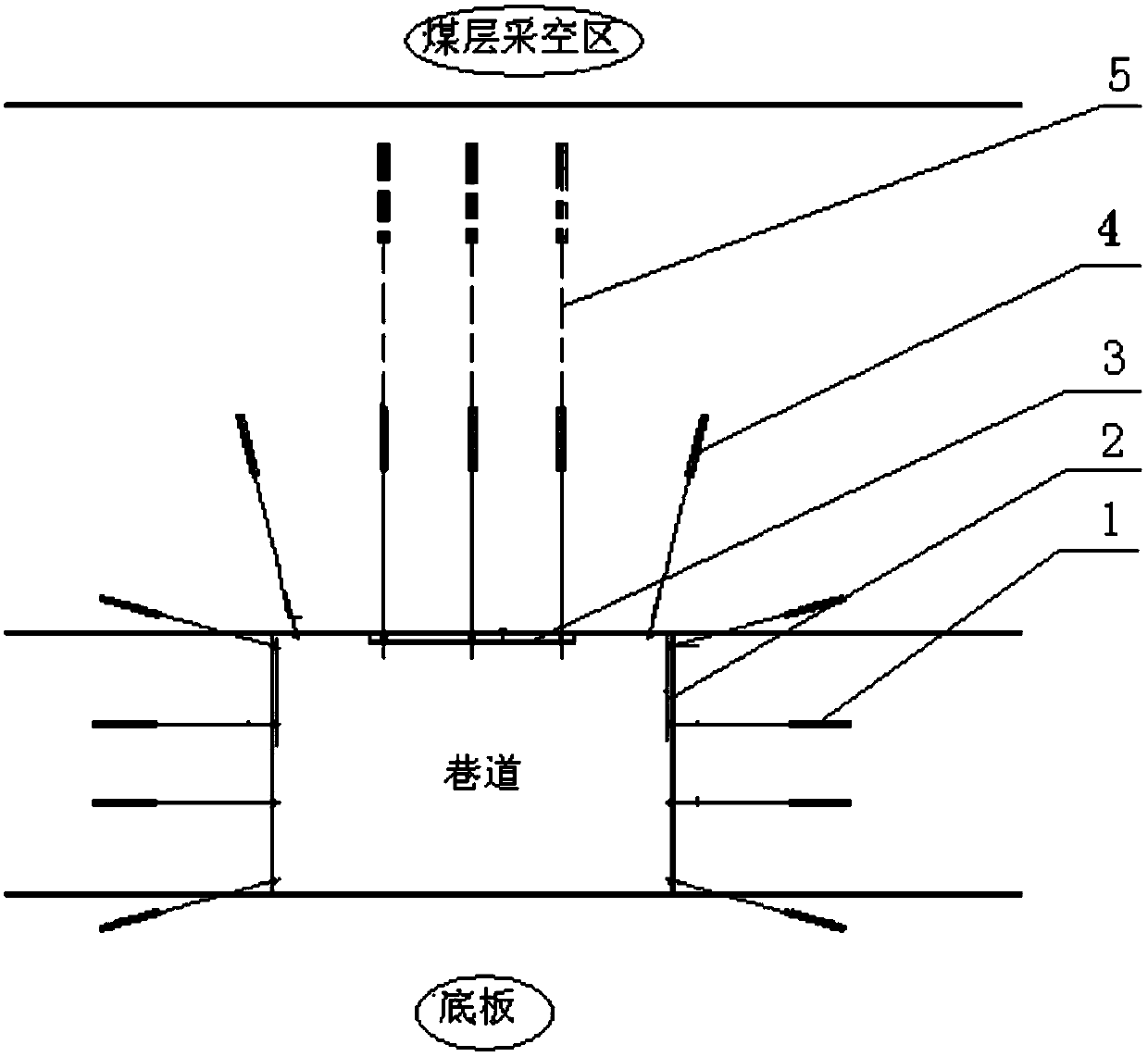

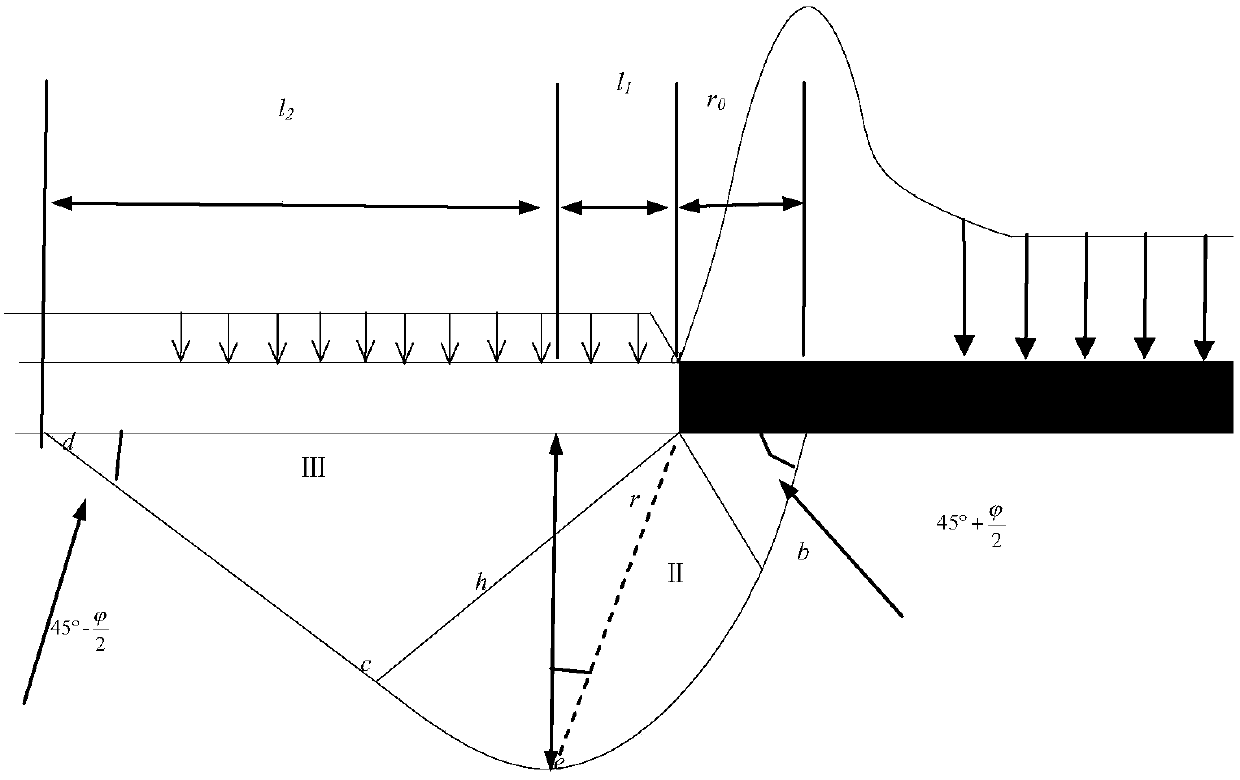

[0055] A method for designing support parameters of short-distance coal roadways under gobs in coal mines, the steps of which are as described in the summary of the invention, wherein image 3 It also shows the calculation principle of the yield damage depth of the bottom plate due to the influence of the support pressure, which is used for the first step to calculate the damage depth h of the bottom plate σ time reference.

[0056] Taking the working face roadway of 11# coal seam 101 of Tuanbai Coal Mine as an example, the embodiment will be further described below.

[0057] The 11-101 working face of Tuanbai Coal Mine is located on the right wing of the first mining area of the lower group coal (Taiyuan Group), surrounded by solid coal, and the upper part is the 10# coal seam goaf, and the distance between the 11# coal seam and the 10# coal seam goaf is average 5.4m, burial depth of coal seam in 11-101 working face = 340m; coal seam thickness 3.1-3.3m, average 3.2m, coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com