Hot-pressed steel sheet member, production method for same, and steel sheet for hot pressing

A technology of hot-dip galvanizing and manufacturing method, which is applied in manufacturing tools, chemical instruments and methods, hot-dip plating process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

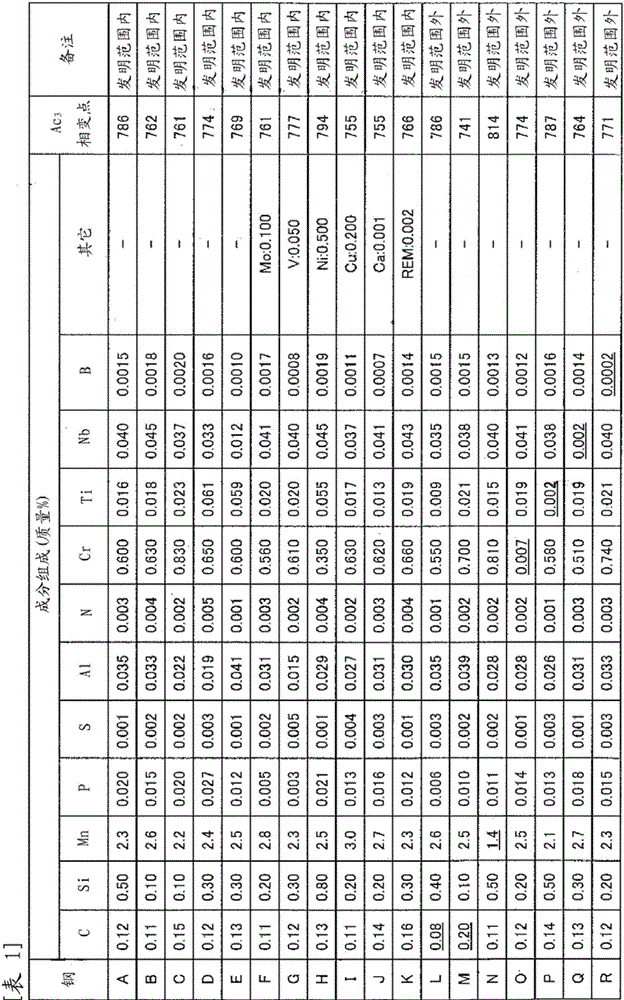

[0127] Steels having the compositions shown in Table 1 were melted in a vacuum melting furnace, and billets were produced by billet rolling. It should be noted that in Table 1, N is an unavoidable impurity.

[0128]

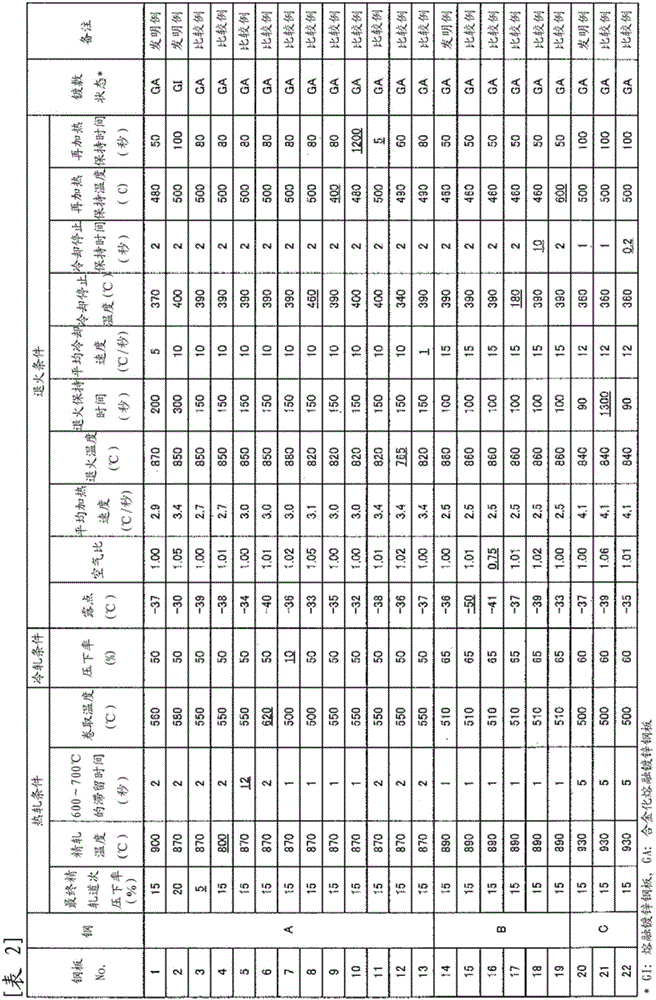

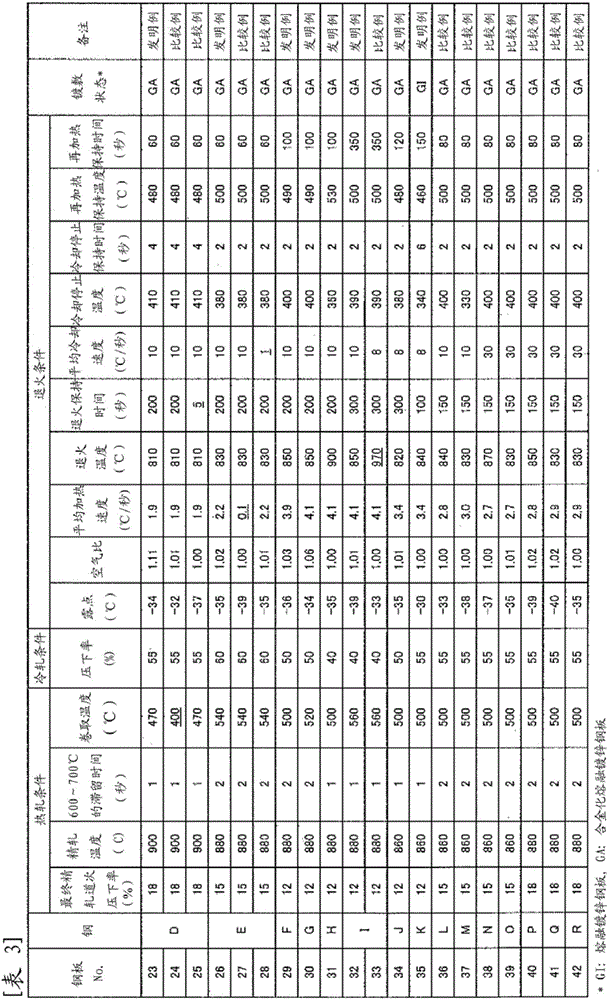

[0129] These slabs were heated to 1200°C, rough-rolled, finish-rolled, and coiled to produce hot-rolled sheets. Next, it was cold-rolled to 1.4 mm to make a cold-rolled sheet, and the obtained cold-rolled sheet was subjected to annealing. The hot rolling conditions, cold rolling conditions and annealing conditions are shown in Tables 2 and 3. Immerse the steel plate prepared under the conditions shown in Table 2 and 3 in a coating bath at 460°C to form a coating with a coating weight of 35-45g / m 2 The hot-dip galvanized layer was then cooled at a cooling rate of 10°C / sec to obtain a hot-dip galvanized steel sheet (GI). In addition, some steel sheets were subjected to alloying treatment at 530°C after the hot-dip galvanized layer was formed, and cooled at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com