Real-time target spraying control system and spraying method of greenhouse sprayer

A control system and spray control technology, which is applied in the device, application, animal husbandry and other directions of capturing or killing insects, can solve the problems of large environmental impact of infrared sensors, short detection distance, low target recognition accuracy, etc. The uniformity of drip coverage, strong anti-interference ability and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

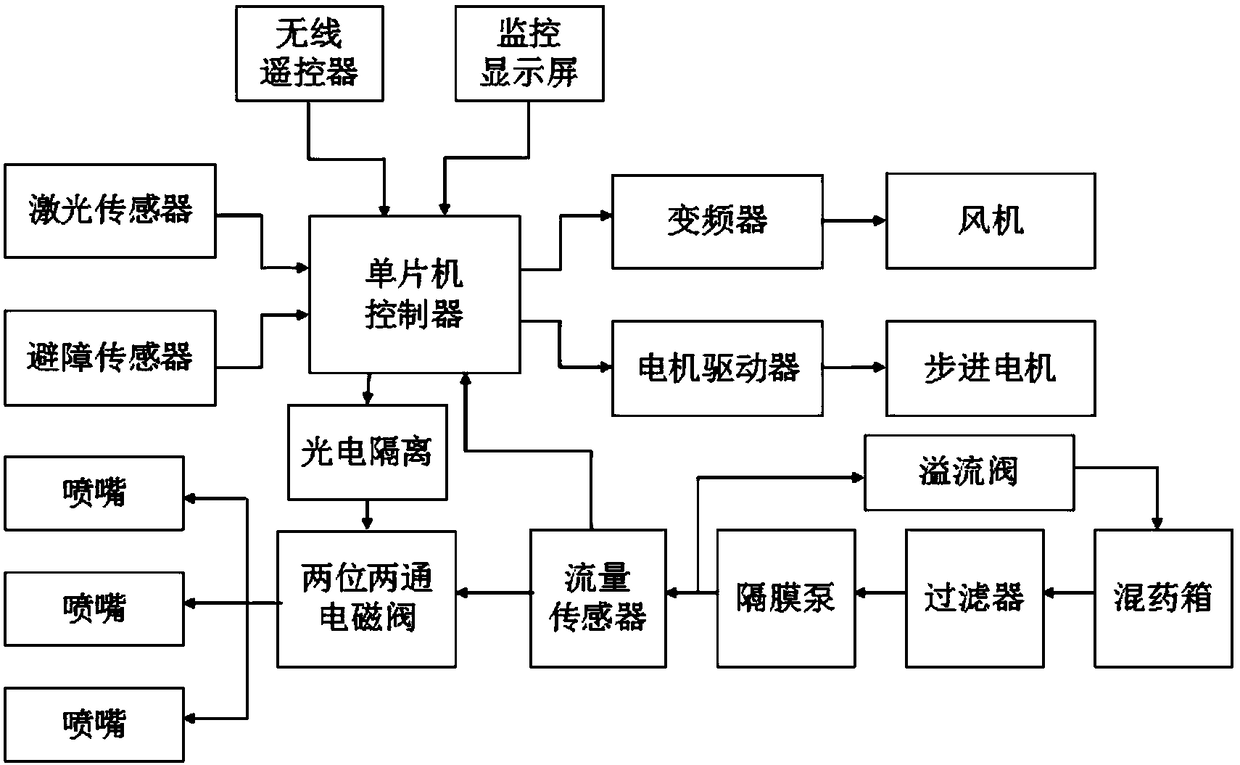

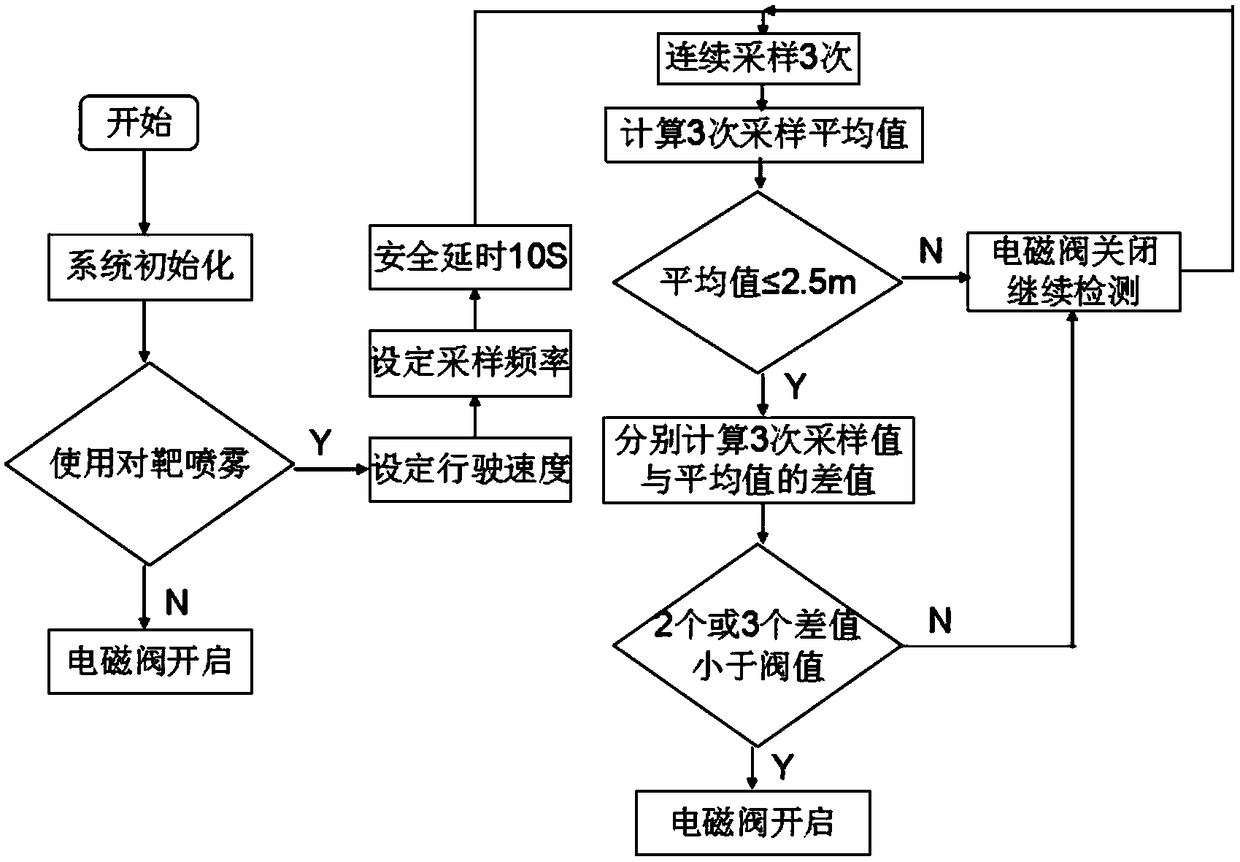

[0028] see figure 1 As shown, the real-time target spraying control system of the greenhouse sprayer includes a single-chip controller, a laser sensor, an obstacle avoidance sensor, a monitoring display screen, a wireless remote control, a motor driver, a motor, a mixing box, a filter, a diaphragm pump, and a flow sensor , two-position two-way solenoid valve, overflow valve and multiple nozzles; wherein: the single-chip controller is connected with the laser sensor, obstacle avoidance sensor, wireless remote control, monitoring display screen, motor driver, flow sensor, two-position two-way The nozzle, the two-position two-way electromagnetic valve, the flow sensor, the diaphragm pump, the filter, and the mixing box are connected in sequence.

[0029] The laser sensor is connected to the analog-to-digital conversion module through the I / V conversion circuit. The analog-to-digital conversion module quickly transmits the detected distance information of the fruit tree canopy to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com