Compressed air foam plug box system and fire extinguishing method for tunnel rescue station

A compressed air foam and rescue station technology, applied in fire rescue and other directions, can solve the problems that the actual application requirements of tunnel rescue stations cannot be met, the deluge system is not suitable for tunnel rescue stations, and foam is difficult to apply, so as to ensure the high efficiency of fire extinguishing, Guaranteed safety and reliability, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

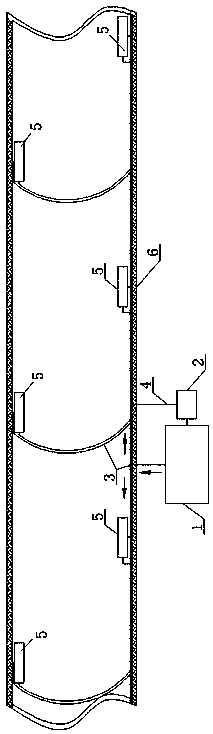

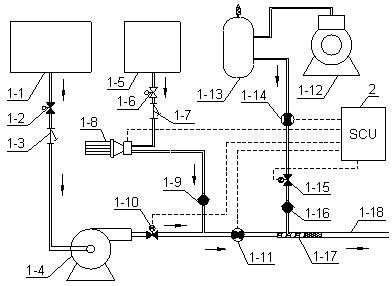

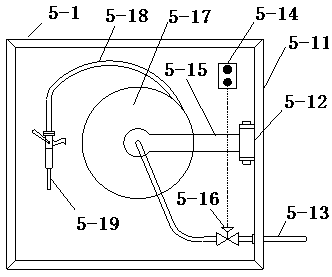

[0023] Such as figure 1 As shown, a compressed air foam lock box system for a tunnel rescue station includes a compressed air foam generator 1 , a system controller 2 , and a compressed air foam lock box 5 .

[0024] The compressed air foam generating device 1 and the system controller 2 are arranged in the equipment chamber of the tunnel 6 rescue station, and several compressed air foam plug boxes 5 are respectively arranged on the two side walls of the tunnel 6 rescue station, and several compressed air foam plug boxes The box 5 is connected with the compressed air foam generator 1 respectively through the foam pipeline 3, and several compressed air foam plug boxes 5 are connected with the system controller 2 through the signal control line 4 respectively, and the compressed air foam generator 1 is connected with the system controller 2 through the signal control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com