A kind of preparation method and application of nano platinum oxide catalyst

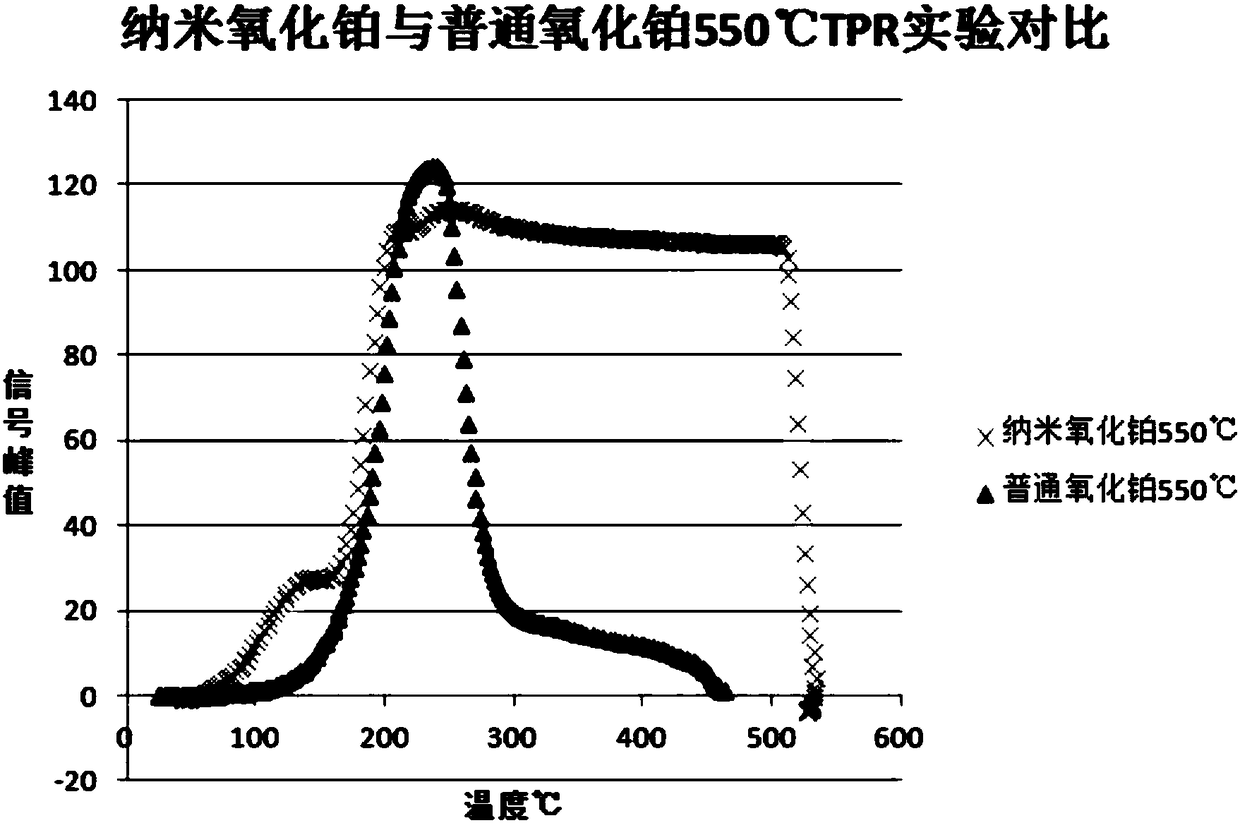

A nano-platinum oxide and catalyst technology, applied in the field of catalysis, can solve the problems of reducing the effective and full utilization of precious metals, weak catalytic activity of precious metal alloys, and small specific surface area, so as to improve distribution rate and use efficiency, strong catalytic performance, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

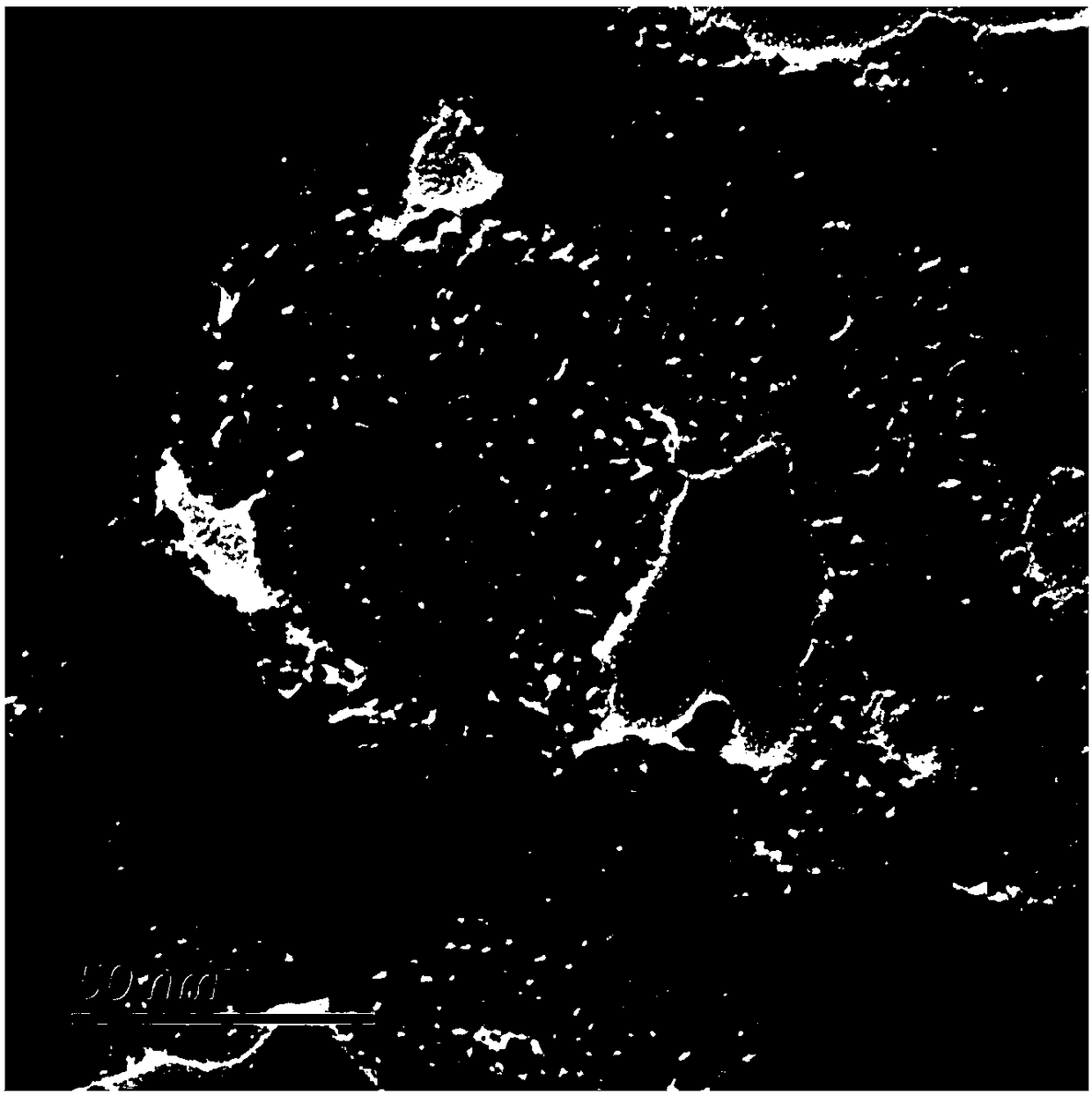

[0029] Weigh 1.5g of platinum nitrate powder and put it into 250mL of deionized water to fully dissolve it to obtain a platinum nitrate solution; weigh 4g of sodium hydroxide and put it into a beaker filled with 50ml of deionized water, stir fully to obtain Sodium solution; add 4mL oleic acid to the prepared sodium hydroxide solution, and place the beaker in an ultrasonic cleaner and stir vigorously to fully dissolve the oleic acid (until there is no blocky oleic acid in the solution), to obtain a sodium oleate solution (oleate solution), (the amount of NaOH added needs to keep the pH of the sodium oleate solution ≥ 10); heat the 250ml platinum nitrate solution configured above to about 65°C (or at room temperature), and then stir the platinum nitrate Quickly add the prepared sodium oleate solution to the solution to obtain a mixed solution of platinum hydroxide and oleate, and keep stirring for 10 minutes to make the reaction more uniform; add 50ml (0.1mol / L) ten Hexaalkyltri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap