Cleaning line for crankcases

A technology for cleaning lines and crankcases, applied in the fields of crankcase processing parts and crankcase cleaning lines, can solve the problems of inconvenient use, difficult cleaning of deep stains, poor cleaning effect, etc., and achieve the effect of high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

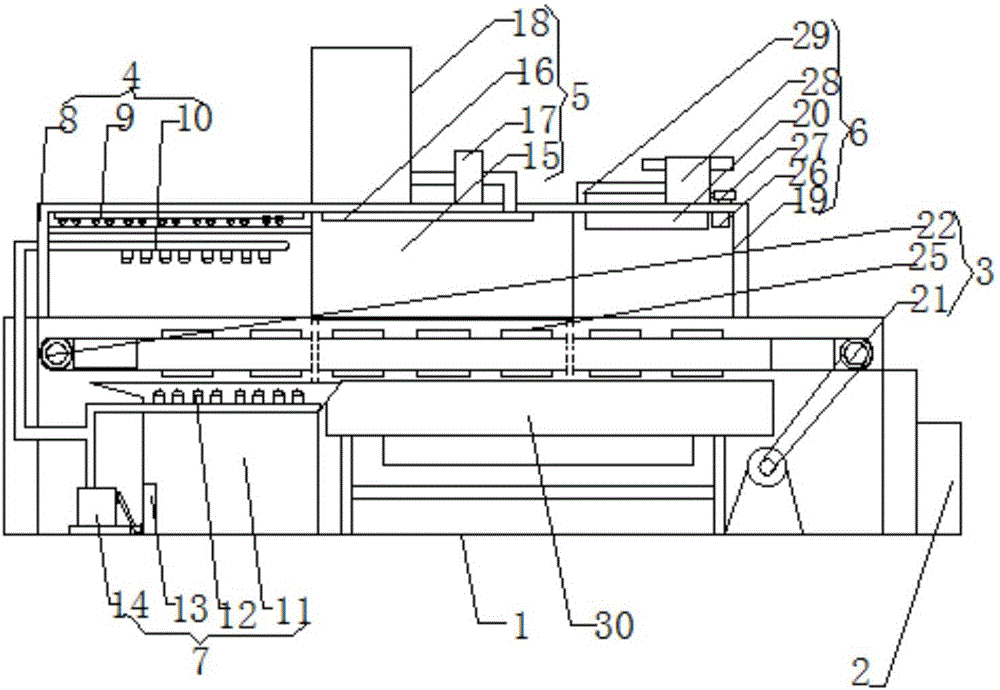

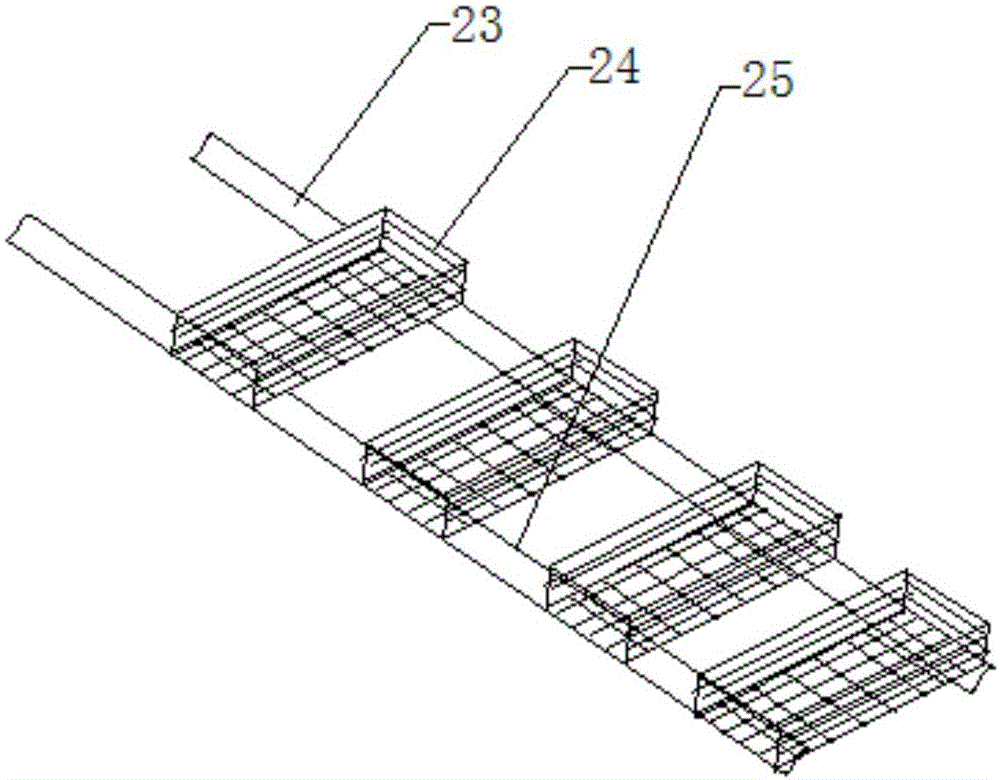

[0015] Such as figure 1 with figure 2 The shown crankcase cleaning line includes a base body 1, an electric control box 2 for total circuit control is installed on the side of the base body 1; a crankshaft transmission mechanism 3 is installed on the base body 1; The crankshaft is sent to the seat body 1 in turn, and the seat body 1 is sequentially provided with a degreasing spray cleaning mechanism 4, a flushing mechanism 5 and a drying mechanism 6 above the crankshaft transmission mechanism 3; A lower degreasing spray mechanism 7 is arranged below the mechanism 3;

[0016] The degreasing spray mechanism 4 includes a first cavity 8; an ultrasonic cleaning probe 9 and an upper degreasing spray pipe 10 are installed inside the first cavity 8; the lower degreasing spray mechanism 7 includes a lower cavity 11; A lower degreasing spray pipe 12 is installed inside the lower cavity 11; the bottom of the lower cavity 11 is connected to the first pump body 14 through a filter 13; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com