Organic garbage microorganism treatment device

A technology for microbial treatment and organic waste, applied in the direction of solid waste removal, etc., can solve the problems of slow decomposition speed of anaerobic fermentation, low organic waste reduction rate, and affecting treatment efficiency, etc., achieve short decomposition time and reduce disposal Burden, processing efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the present invention will be further described below in conjunction with the examples.

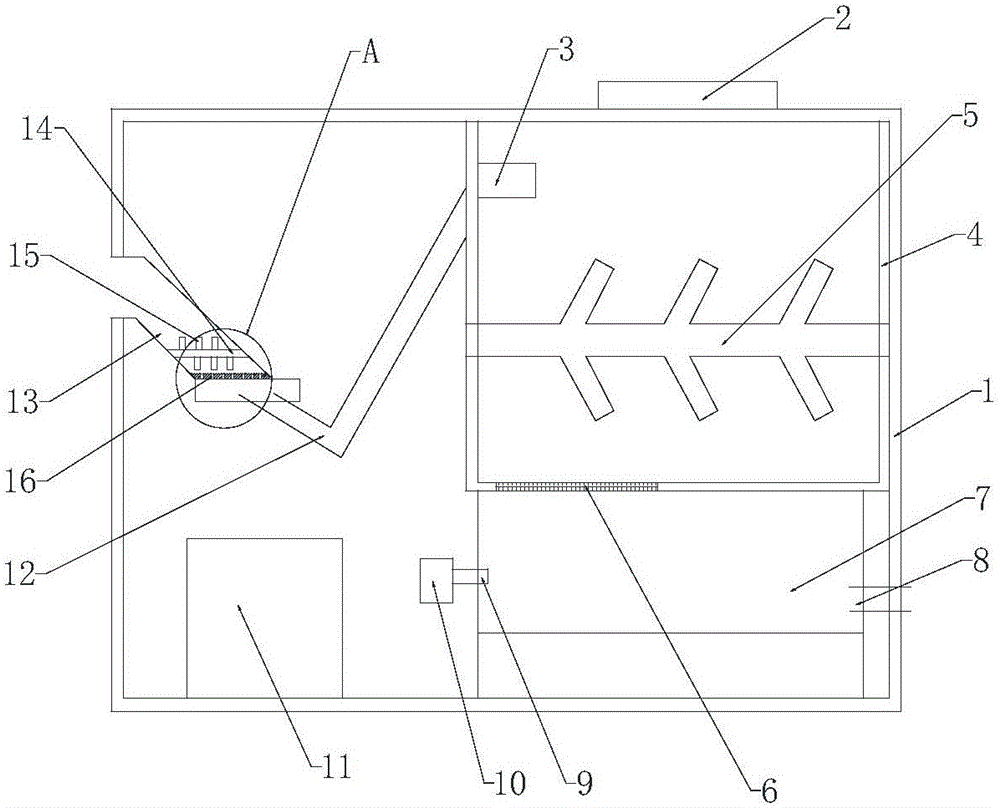

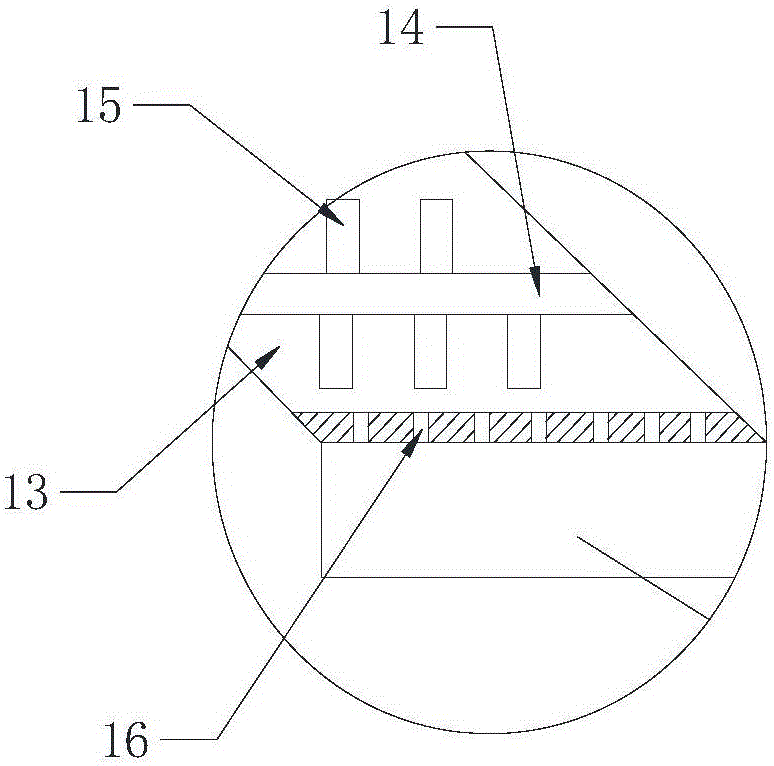

[0025] like figure 1 and figure 2 As shown, the organic waste microbial treatment integrated machine includes a casing, which is equipped with a control box, a garbage decomposition device, a front crushing device, and a feeding auger. The front crushing device is connected to the feeding auger. The auger is connected to the garbage decomposition device. The front crushing device includes a cylindrical material channel and a crushing device installed in the material channel. The upper end of the material channel is connected to the casing, and the casing is provided with a cover for covering the opening of the upper end of the material channel. The lower end of the material channel is provided with a number of through holes for the crushed garbage to fall into the feeding auger. Through this process, the larger objects in the garbage can be broken a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com