Electro-hydraulic hybrid power drive system

An electro-hydraulic hybrid and power-driven technology, applied in hybrid vehicles, power units, pneumatic power units, etc., can solve the problems of inability to meet the requirements of working conditions, insufficient starting and climbing ability, and unstable engine stability. The effect of high oil rate, diversified working modes, and market competitive advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

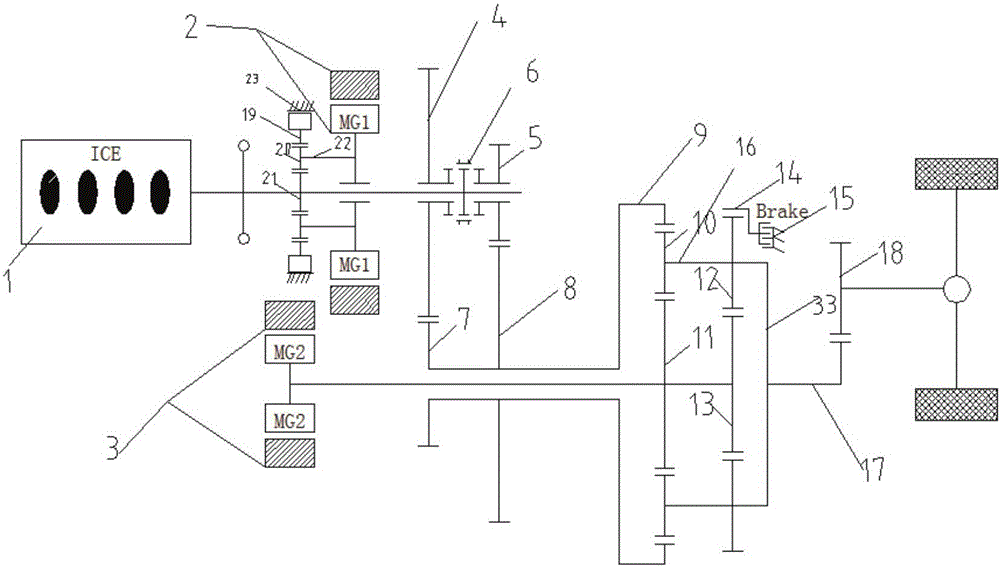

Embodiment 1

[0047] like figure 1 As shown, the shaft directly connected between the first motor 2 and the engine 1 is connected to a planetary row, and the planetary row includes a third ring gear 19, a third planetary gear 20, a third sun gear 21, and a third planet carrier 22. The engine 1 is coaxially connected to the third sun gear 21, the first motor 2 is sleeved on the shaft connected to the engine 1, and the first motor 2 is connected to the third planetary gear 20 through the third planet carrier 22. The third planetary gear 20 is meshed with the third sun gear 21 and the third ring gear 19 . The outer ring of the third ring gear 19 is provided with a second brake 23 , and the second brake 23 controls the movement state of the third ring gear 19 through separation or combination.

[0048] The shaft directly connected between the second motor 3 and the sun gear is a direct shaft connection, that is, the second motor 3 is coaxially connected with the first sun gear 11 and the secon...

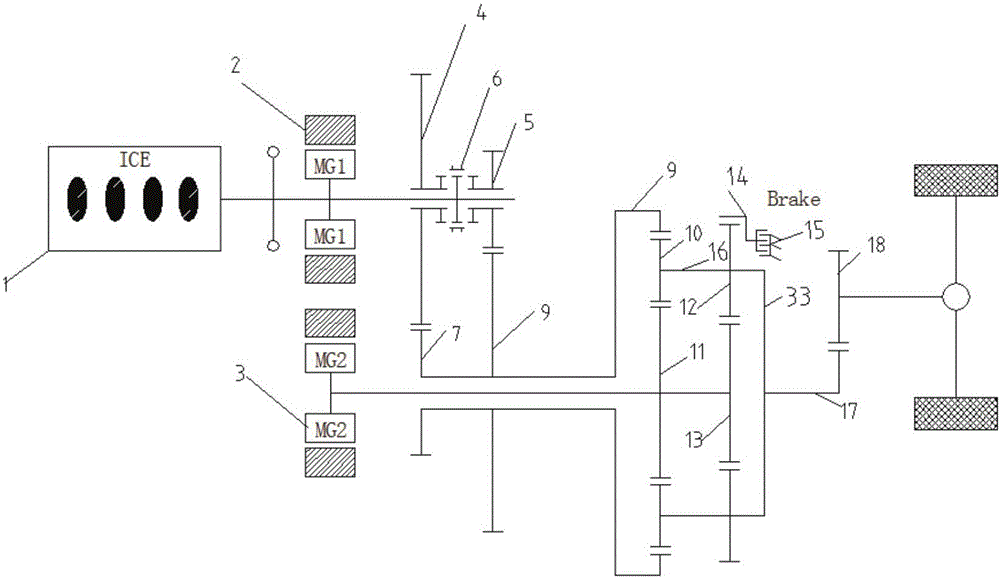

Embodiment 2

[0057] like figure 2 As shown, the shaft directly connected between the first motor 2 and the engine 1 is a direct shaft connection, that is, the first motor 2 and the engine 1 are coaxially connected. By connecting in this way, a quick start of the engine 1 can be realized. While the engine 1 is working, the first motor 2 is driven to generate electricity, and the first motor 2 outputs power to the second motor 3 to ensure that the second motor 3 has sufficient power to work, increase the coupling power, and reduce the working time of the engine fuel consumption.

[0058] The shaft directly connected between the second motor 3 and the sun gear is a direct shaft connection, that is, the second motor 3 is coaxially connected with the sun gear, and the second motor 3 is on the same shaft as the first sun gear 11 and the second sun gear 13 . Connected in this way, the forward speed of the car can be controlled directly by controlling the rotating speed of the second motor 3. W...

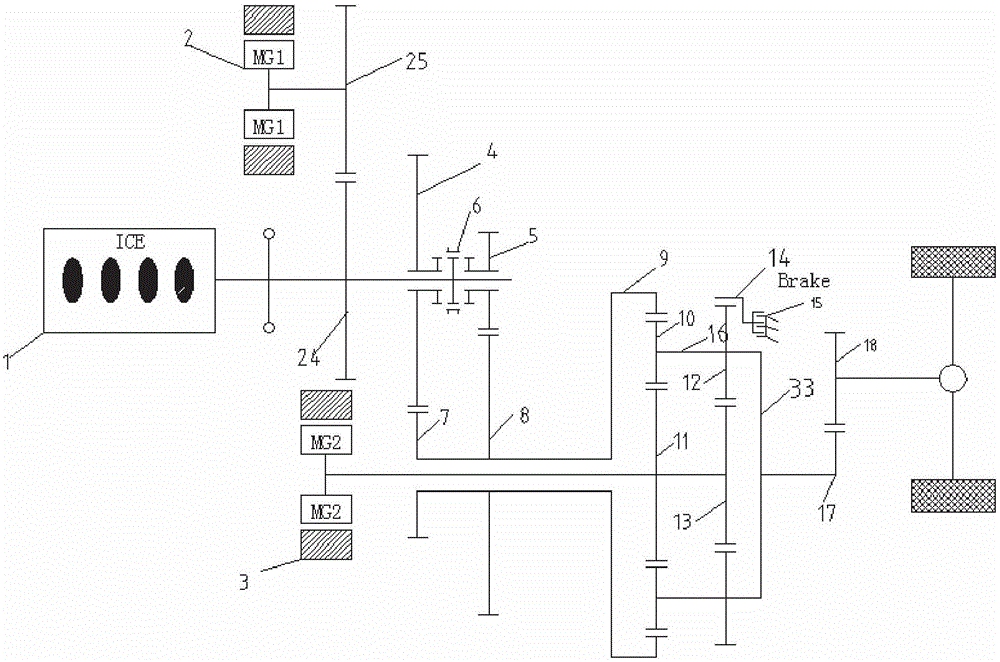

Embodiment 3

[0066] like image 3 As shown, the shaft directly connected between the first motor 2 and the engine 1 is geared, that is, the first motor 2 is fixedly connected with the eighth gear 25, the engine 1 is coaxially connected with the seventh gear 24, and the seventh gear 24 is connected with the eighth gear 25. The gears 25 are meshed. The engine 1, the seventh gear 24, the first gear 4, the second gear 5, and the double wet clutch 6 are on the same shaft. The first motor 2 is connected to the shaft connected to the engine by using gears, and by using gears of different sizes, relying on the speed ratio to output, it can provide a certain deceleration effect, so that the engine 1 can match the transmission power provided by the second motor 3 Matching, increase transmission power. And when starting the engine 1, the engine 1 can be started quickly by a smaller rotating speed.

[0067] The shaft directly connected between the second motor 3 and the sun gear is a direct shaft c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com