Traction systems for elevators

A traction system and traction technology are applied in the field of elevators to improve the surface protection performance and avoid slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

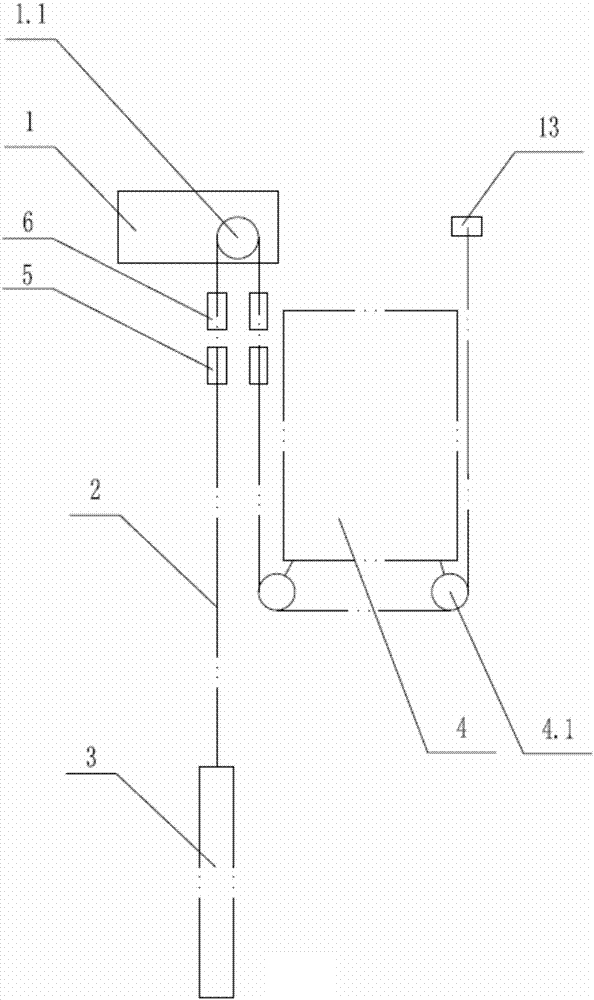

[0019] The invention provides a traction system for an elevator, which includes a traction machine 1 installed in the elevator shaft, a traction wire rope 2 and a counterweight 3 arranged under the traction machine 1, and is characterized in that: the traction wire rope One end of 2 is fixed to the inner wall of the elevator shaft, the other end of the traction wire rope 2 is fixed to the counterweight 3, and the middle part of the traction wire rope 2 is wound around the guide wheel 4.1 at the bottom of the car 4 and the center of the traction machine 1 in turn. On the driving wheel 1.1, surface treatment mechanisms for treating the surface of the traction wire rope 2 are provided between the counterweight 3 and the driving wheel 1.1 and between the guide wheel 4.1 of the car 4 and the driving wheel 1.1;

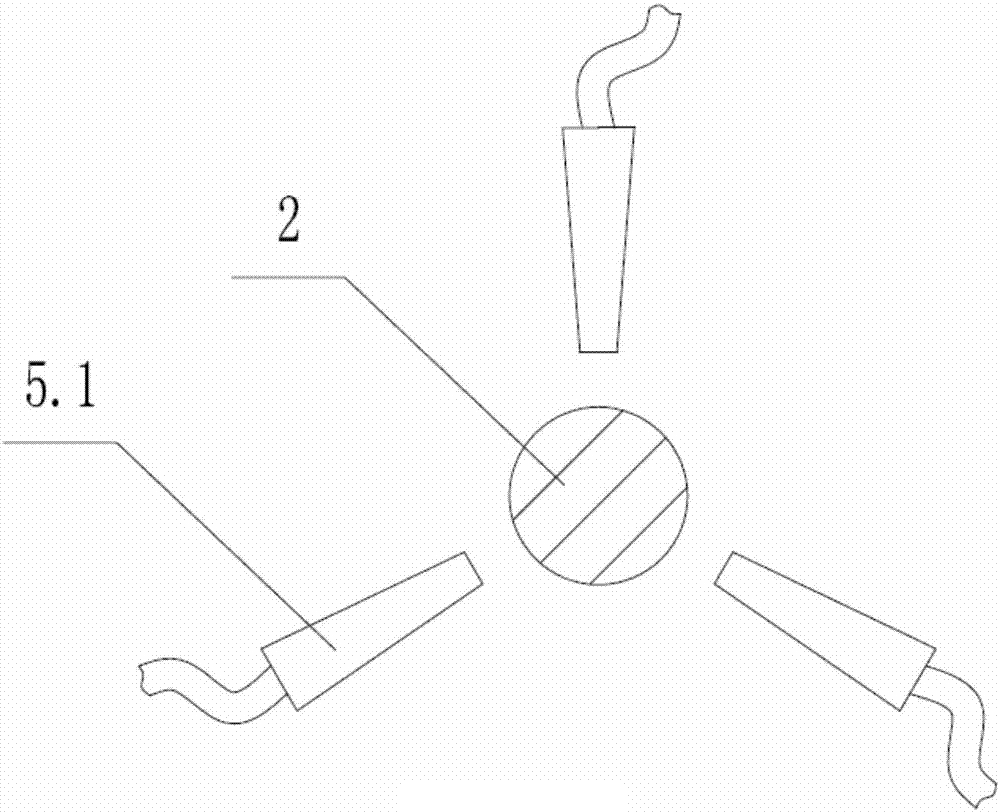

[0020] The surface treatment mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com