A kind of production method of continuous functional composite material

A composite material and production method technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of low bonding strength, narrow operating temperature range, inability to accurately control the curing reaction process, etc. The effect of bonding strength, improving surface cleanliness, and broadening the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

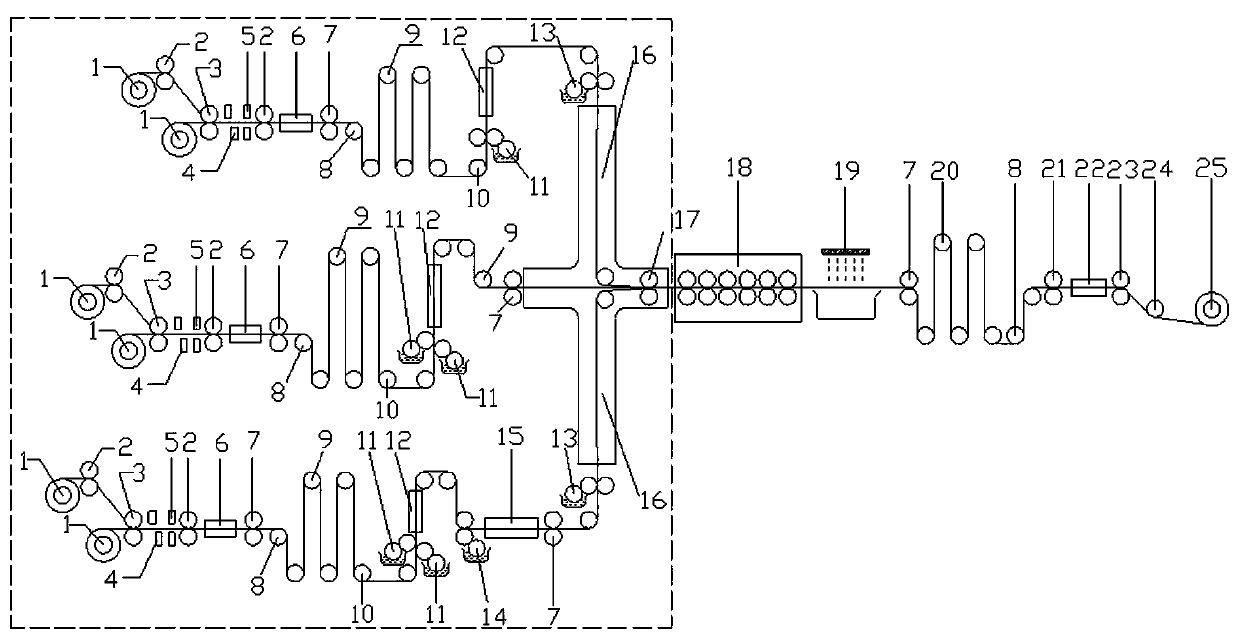

[0032] Such as figure 1 Shown, a kind of production method of continuous functional composite material: After surface-treating the aluminum coil of the upper layer strip, the galvanized steel coil of the middle layer strip and the aluminum coil of the lower layer strip, respectively by the respective corresponding chemical coating machines 11 One-sided coating is carried out on the composite surface (lower surface) of the upper strip, and a layer of chemical coating solution is applied on both sides of the middle and lower strips, and dried in a chemical coating drying oven; the back of the lower aluminum coil is coated with a A layer of liquid polyurethane paint is dried in the back coating drying furnace 15; then a layer of liquid polymer damping material is coated on the upper and lower layers of aluminum coils by a roller coater 13, and then enters the preheating furnace 16 to volatilize the solvent of the polymer damping material and strip preheating, the preheating tempe...

Embodiment 2

[0034] Such as figure 1 Shown, a kind of production method of continuous functional composite material: After surface treatment, the 304 stainless steel coil of the upper strip material, the aluminum coil of the middle layer strip material and the 304 stainless steel coil of the lower layer strip are processed by respective chemical coating machines 11 respectively. One-sided coating is carried out on the composite surface (lower surface) of the upper layer strip, and a layer of chemical coating solution is applied on both sides of the middle and lower layer strips, and dried in a chemical coating drying oven; the back of the lower layer strip is 304 stainless steel coil Coat a layer of liquid acrylic paint and dry it in the back coating drying furnace 15; then coat a layer of liquid polymer damping material on the upper and lower aluminum coils by a roller coater 13, and enter the preheating furnace 16 for polymer damping The solvent volatilization of the material and the pre...

Embodiment 3

[0036] Such as figure 1 As shown, a production method of a continuous functional composite material: After the upper strip copper coil, the middle layer aluminum strip and the lower strip copper coil are surface-treated, the corresponding chemical coating machines 11 are respectively applied on the upper layer The composite surface (lower surface) of the strip is coated on one side, and the middle and lower strips are coated with a layer of chemical coating solution on both sides, and dried in a chemical coating drying oven; the back of the aluminum coil of the lower strip is coated with a A layer of liquid polyurethane paint is dried in the back coating drying furnace 15; then a layer of liquid polymer damping material is coated on the upper and lower layers of aluminum coils by a roller coater 13, and then enters the preheating furnace 16 to volatilize the solvent of the polymer damping material and the preheating of the strip, the preheating temperature is 100°C; and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com