Toughened and modified PVC (polyvinyl chloride) plastic pipe and preparation method thereof

A plastic pipe, toughening modification technology, applied in the field of toughened modified PVC plastic pipe and its preparation, can solve the problems of the restriction and influence of the strengthening effect of PVC pipe, the limited degree of modification of the molecular structure skeleton of PVC pipe, etc., to achieve increased Good toughness effect, improved low temperature brittleness, and improved elastoplasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

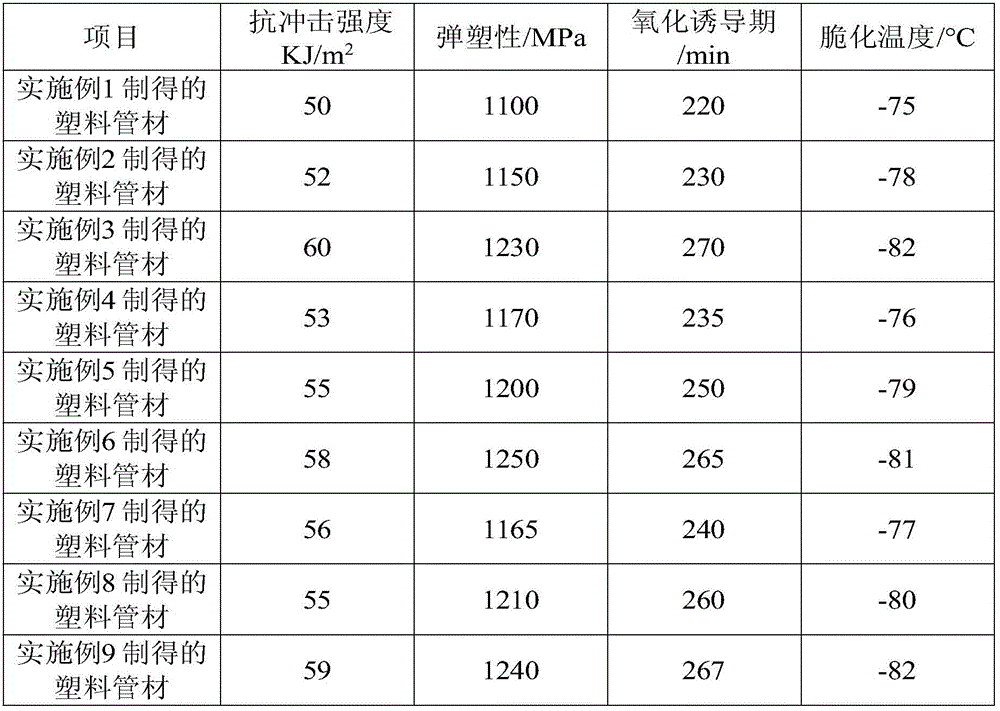

Examples

Embodiment 1

[0036] A toughened modified PVC plastic pipe, the raw material for preparing the toughened modified PVC plastic pipe and its parts by weight are: 100 parts of polyvinyl chloride resin, 15 parts of high cis-butadiene rubber, 0.5 part of coupling agent, and inorganic filler 0.2 parts; the molecular weight of polyvinyl chloride resin is 60000; the molecular weight of high cis-butadiene rubber is 45000; the coupling agent is titanate coupling agent; the inorganic filler is silicate with a particle size of 0.1 μm. Where the silicate is ZrSiO 4 .

Embodiment 2

[0038] A toughened modified PVC plastic pipe, the raw materials and parts by weight for preparing the toughened modified PVC plastic pipe are: 100 parts of polyvinyl chloride resin, 35 parts of high cis-butadiene rubber, 1.5 parts of coupling agent, and inorganic filler 0.6 parts; wherein the molecular weight of polyvinyl chloride resin is: 120,000; the molecular weight of high cis-butadiene rubber is: 90,000; the coupling agent is: titanate coupling agent; the inorganic filler is phosphate with a particle size of 0.5 μm. where phosphate is Ca 3 (PO 4 ) 2 .

Embodiment 3

[0040]A toughened modified PVC plastic pipe, the raw material for preparing the toughened modified PVC plastic pipe and its parts by weight are: 100 parts of polyvinyl chloride resin, 25 parts of high cis-butadiene rubber, 1.0 part of coupling agent, and inorganic filler 0.4 parts; the molecular weight of polyvinyl chloride resin is 90000; the molecular weight of high cis-butadiene rubber is 68000; the coupling agent is titanate coupling agent; the inorganic filler is phosphate with a particle size of 0.3 μm. Wherein the phosphate is AlPO 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com