Color conversion film and back light unit and display apparatus comprising the same

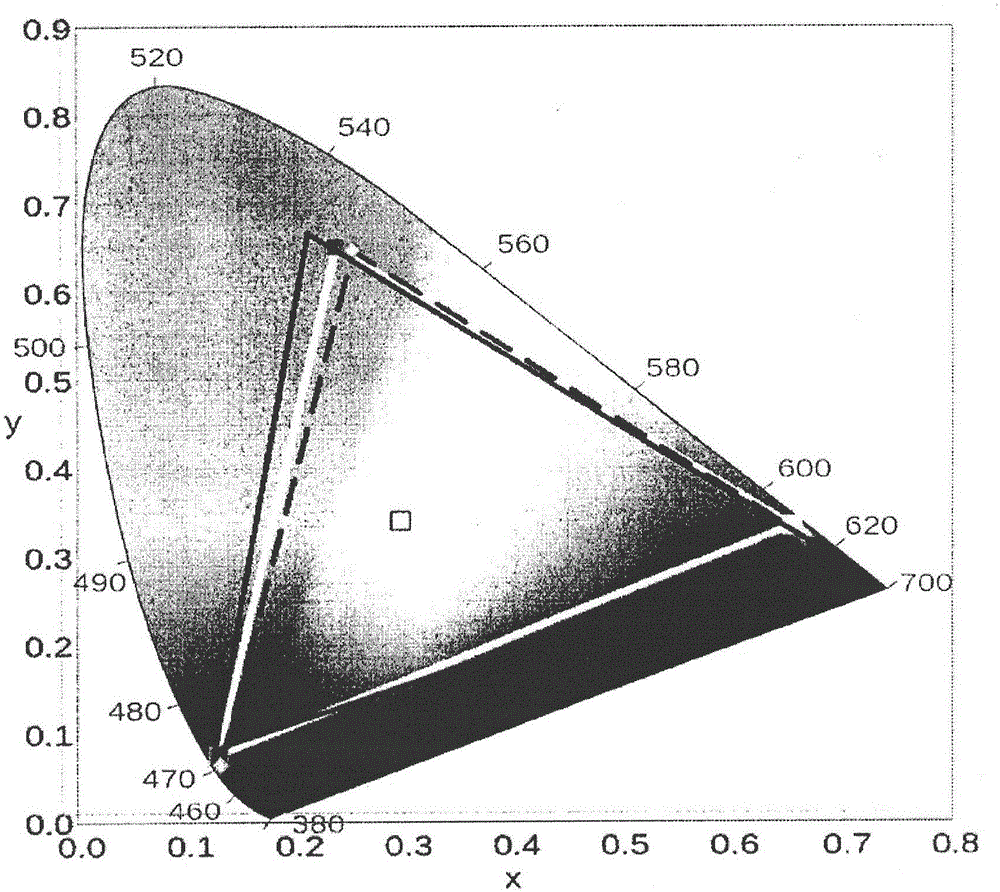

A technology of color conversion and red light, applied in lighting and heating equipment, optical components, light guides of lighting systems, etc., to achieve the effect of enhancing the color gamut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

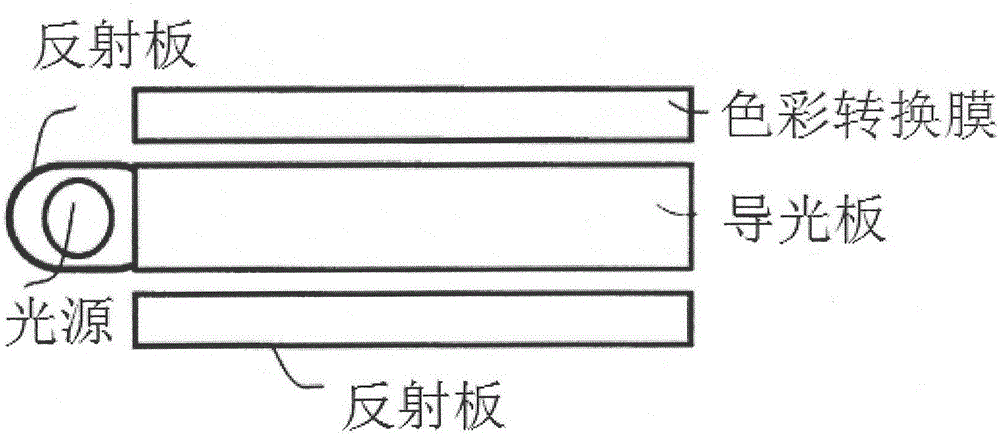

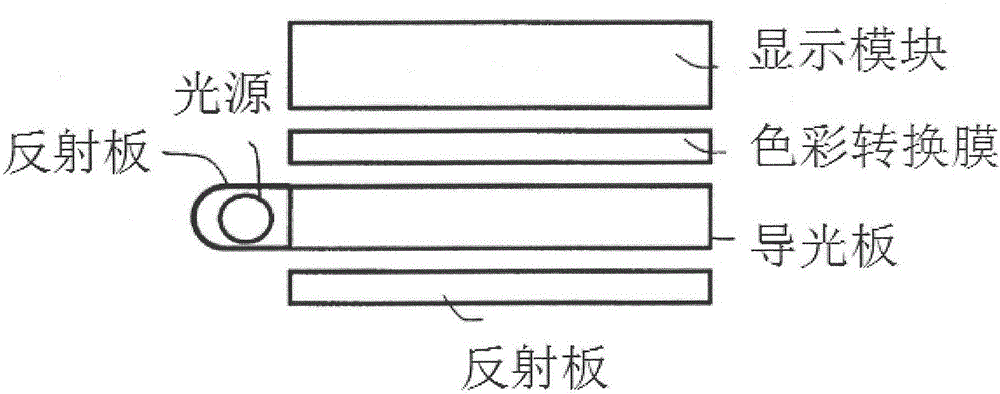

Method used

Image

Examples

Embodiment 1

[0092] A first solution was prepared by dissolving CVP (first fluorescent substance having the following structural formula) and lumogen Red 305 (second fluorescent substance) in a DMF solvent at a molar ratio of 1:2.

[0093]

[0094] (First Fluorescent Substance, CVP)

[0095] A second solution was prepared by dissolving PMMA, a thermoplastic resin, in DMF solvent.

[0096]The first solution and the second solution were mixed so that the sum of the contents of the first fluorescent substance and the second fluorescent substance was 0.3 parts by weight relative to 100 parts by weight of PMMA, and were uniformly mixed. The solid content in the mixed solution was 20 wt%, and the viscosity was 200 cps. This solution was coated on a PET substrate, and the resultant was dried to prepare a color conversion film.

[0097] The luminance spectrum of the prepared color conversion film was measured using a spectroradiometer (SR series of POPCON Corporation). Specifically, the prep...

Embodiment 2

[0099] It was prepared in the same manner as in Example 1 except that the molar ratio of the first fluorescent substance and the second fluorescent substance was 1:1.

Embodiment 3 and 4 and comparative example 3 and 4

[0109] The color conversion films prepared in Examples 1 and 2 and Comparative Examples 1 and 2, the green light-emitting color conversion films comprising the following HPTS compounds, and the blue LED light source were laminated in sequential order, and after driving the liquid crystal panel, evaluation was made from the layers. The color gamut of the light emitted by the press body is shown in Table 1 below. The green light-emitting color conversion film included 0.5 parts by weight of the following HPTS compound with respect to 100 parts by weight of the thermoplastic resin PMMA.

[0110]

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| fluorescence wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com