Silicone powder special for engineering plastic

A technology for engineering plastics and silicone powder, applied in the field of silicone powder, can solve the problems of low mechanical properties of engineering plastics, inability to give full play to the flame retardant properties of flame retardants, low molecular structure strength, etc., so as to improve mechanical properties and strengthen molecular Structural force, the effect of improving fluidity

Inactive Publication Date: 2016-08-10

李凤舟

View PDF1 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the silicone powder of the prior art also has certain defects, especially in the application process of the production process of engineering plastics, its molecular structural strength is not high, so that the mechanical properties of engineering plastics are low, and the flame retardant cannot be fully utilized. flame retardant performance, so it is necessary to improve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

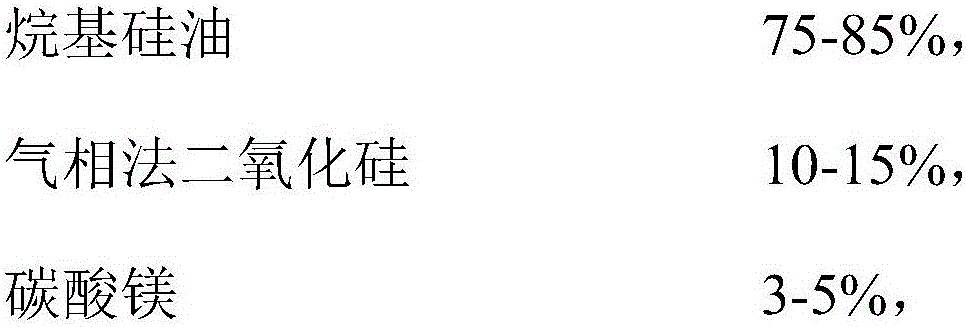

Embodiment 1

[0023] A special silicone powder for engineering plastics, consisting of components in the following weight ratios,

[0024]

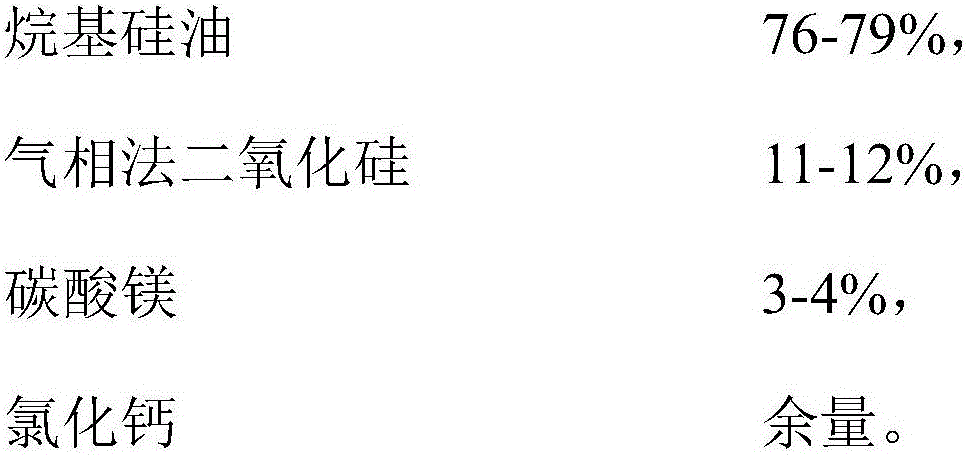

Embodiment 2

[0026] A special silicone powder for engineering plastics, consisting of components in the following weight ratios,

[0027]

Embodiment 3

[0029] A special silicone powder for engineering plastics, consisting of components in the following weight ratios,

[0030]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses silicone powder special for an engineering plastic. The silicone powder consists of the following components in percentage by weight: 75-85% of alkyl silicone oil, 10-15% of fumed silica, 3-5% of magnesium carbonate, and the balance of calcium chloride. The silicone powder is specially used in a production process of an engineering plastic, and the production process of the engineering plastic, after silicone master batches disclosed by the invention are added, has the following advantages: the molecular structure power among engineering plastic molecules is enhanced, the mechanical property of the engineering plastic is improved, the fluidity of the engineering plastic is increased, and especially for a flame-retardant engineering plastic, the fluidity between a flame retardant and other raw materials is improved to ensure that the flame retardant can play a stronger flame-retardant effect and cannot deteriorate due to overheating in a screw for a long time. The silicone powder can regulate the pH value of the engineering plastic and enable the pH value to be neutral, and is nontoxic and harmless.

Description

technical field [0001] The invention relates to the technical field of silicone powder, in particular to a special silicone powder for engineering plastics. Background technique [0002] Silicone powder is a high-efficiency lubricant for ultra-high molecular weight plastics that does not contain organic carriers. It can be integrated with almost all types of thermoplastics and is widely used in the production process of various thermoplastics. It can improve plastic processing fluidity and mold release performance, and reduce torque. , reduce equipment wear, easy mold filling, reduce product defect rate, significantly reduce friction coefficient, improve smooth performance, improve surface gloss, enhance surface silky touch, improve wear resistance and scratch resistance. It is a general plastic lubricant such as It is an upgraded product of EBS and silicone masterbatch plastic lubricant, which overcomes the weakness of traditional silicone oil as a plastic lubricant that is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L83/04C08K3/36C08K3/26C08K3/16C08L23/08

CPCC08L83/04C08K3/16C08K3/26C08K3/36C08K2003/162C08K2003/267C08L2201/02C08L23/0853

Inventor 李凤舟

Owner 李凤舟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com