Closed air curtain cold-proof and heat-preserving special door structure of steam turbine power plant

A technology for power plants and air curtains, applied in nuclear power plants, closed air curtain cold-proof and heat-insulating special door structures, and heat-insulation door structures, can solve problems such as difficult opening/closing operations, increased door thickness, and poor airtight performance Excellent thermal insulation effect, improved thermal insulation performance, and good airtight performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

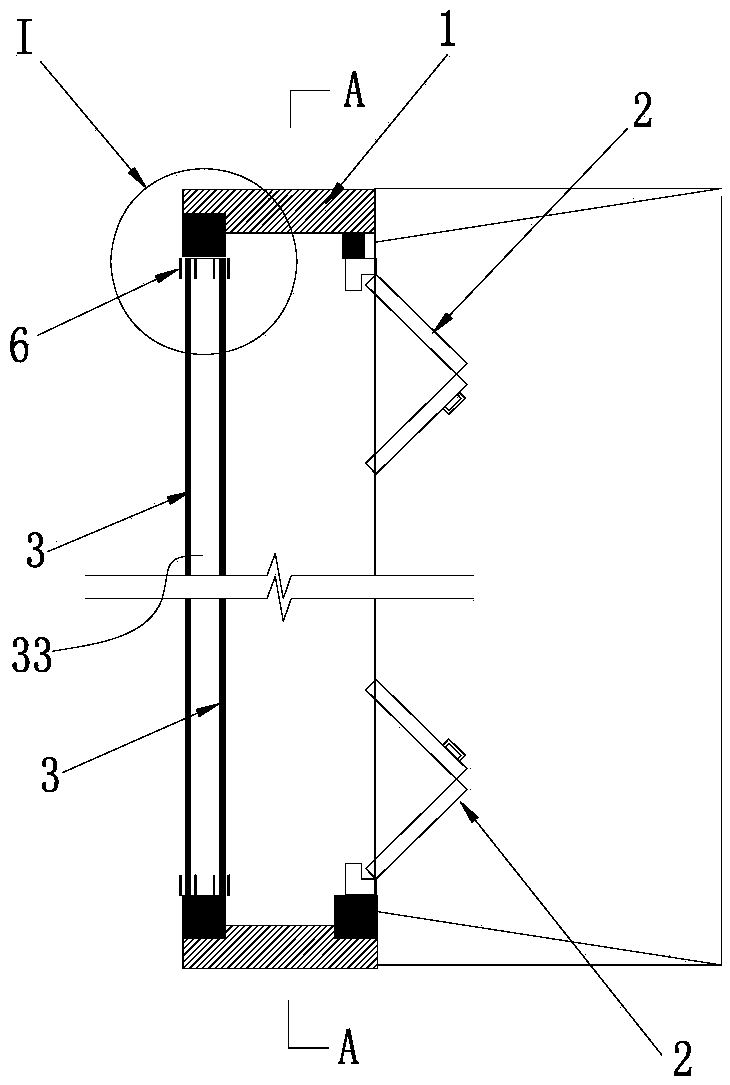

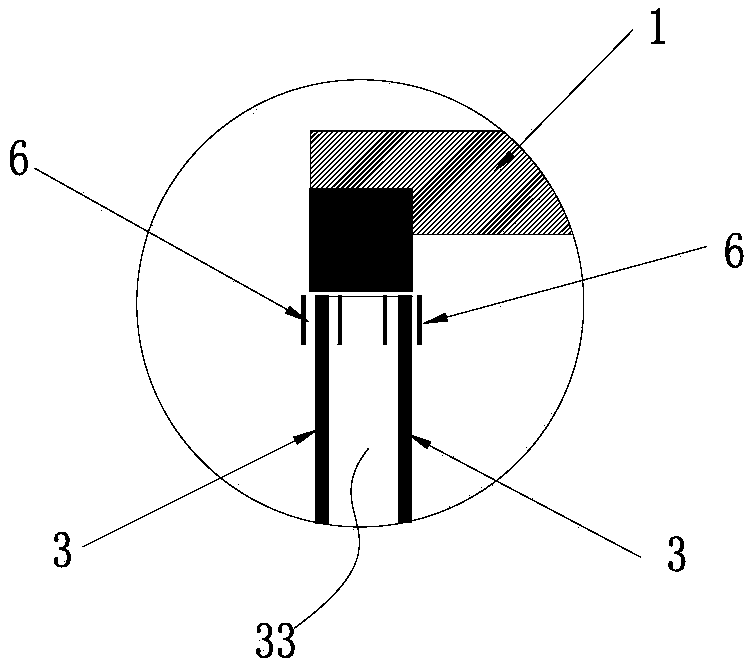

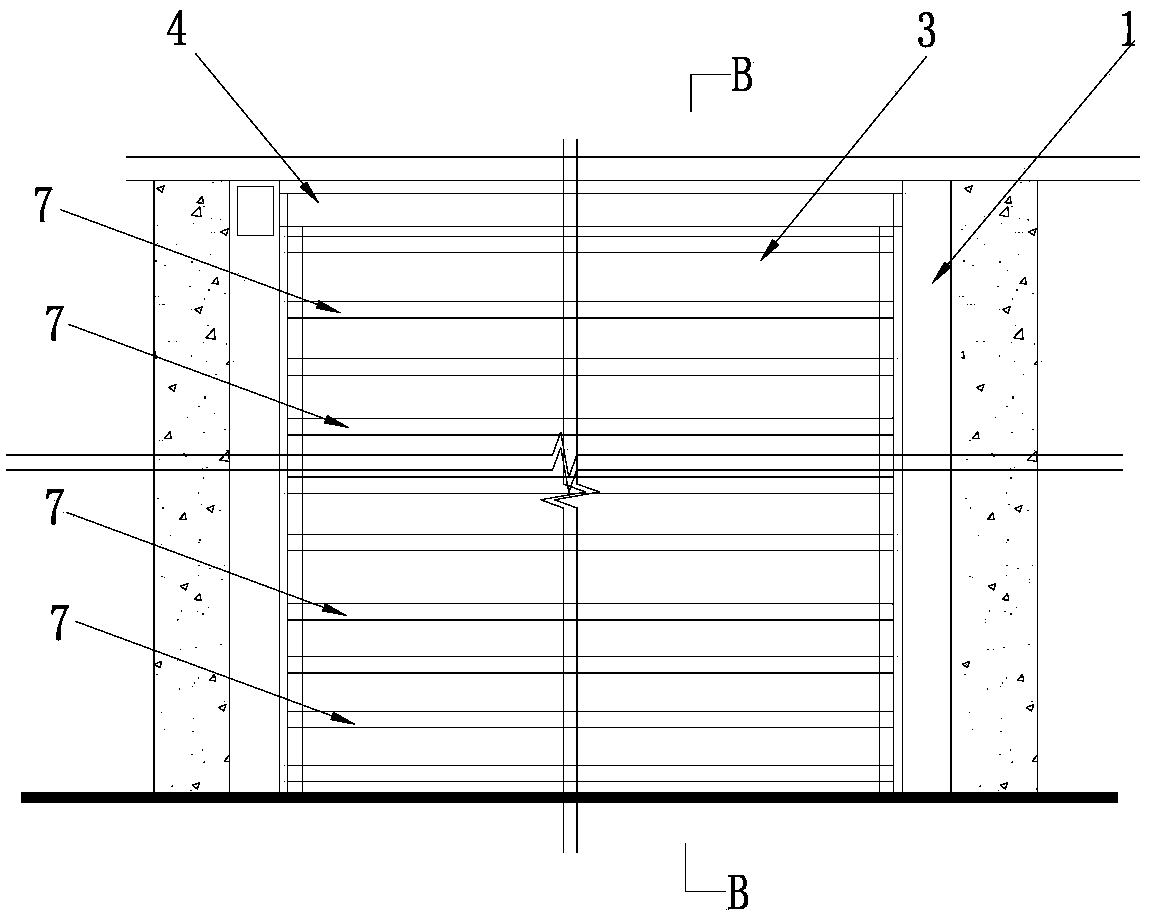

[0027] refer to Figure 1 to Figure 5 The closed air curtain cold-proof and heat-preserving special door structure of the steam turbine power plant shown includes a door frame body 1 and a windproof steel door 2. The windproof steel door 2 is arranged on the outside of the door frame body 1, and at least two floors are arranged on the inside of the door frame body 1. Air cold-proof roller blind 3, a first gap is left between the air cold-proof roller blind 3 and the windproof steel door 2, and a second gap is left between the air cold-proof roller blind 3, forming a double or multi-layer air heat insulation layer Structure; the ground on the outside of the door frame body 1 is set as a downward slope to prevent the formation of cold bridges outdoors; a sealing strip is set around the connection between the windproof steel door 2 and the door frame body 1 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com