Evaluating method and measuring device for uniformity of spray holes of oil sprayer

An evaluation method and technology for measuring devices, which are applied in the testing of measuring devices, fuel injection devices, and machine/structural components, etc., can solve the problems of the injection uniformity and consistency of each hole of the injector, the large measurement error, and the complicated operation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] XXX model four-stroke direct-injection diesel engine is equipped with six cylinders, the bore is 132mm, the stroke is 145, the compression ratio is 17, and the speed is 2000r / min. The above-mentioned XXX engine is equipped with XX type fuel injector, the fuel injector fuel injection frequency is 17Hz, the fuel injection pulse width is 1.6ms, the fuel injection pressure is 100MPa, and has 8 nozzle holes, that is, the value of Z is 8. For the XXX engine, at the end of the compression stroke (the fuel injector has just started injecting fuel, but the fuel has not yet caught fire) the temperature in the cylinder is 820°C, and the pressure is 6MPa.

[0099] For above-mentioned XXX engine and XX fuel injector, present embodiment will introduce in detail how to use the present invention, under the operating condition of this engine, test the consistency, durability, uniformity of XX fuel injector.

[0100] According to the description in the main body of the manual, assemble t...

Embodiment 2

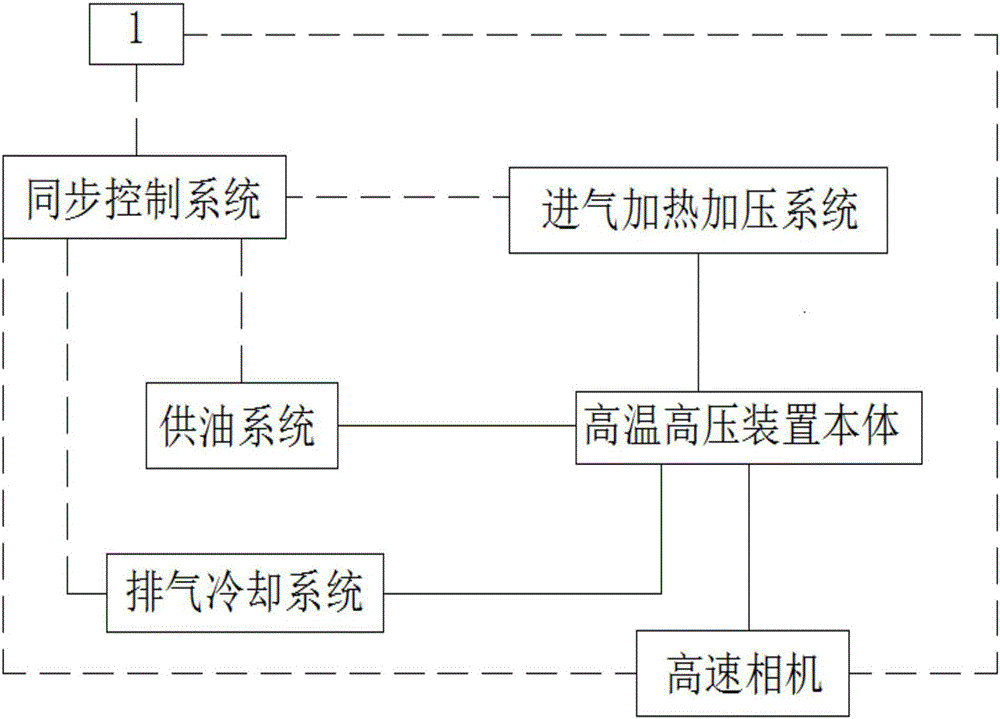

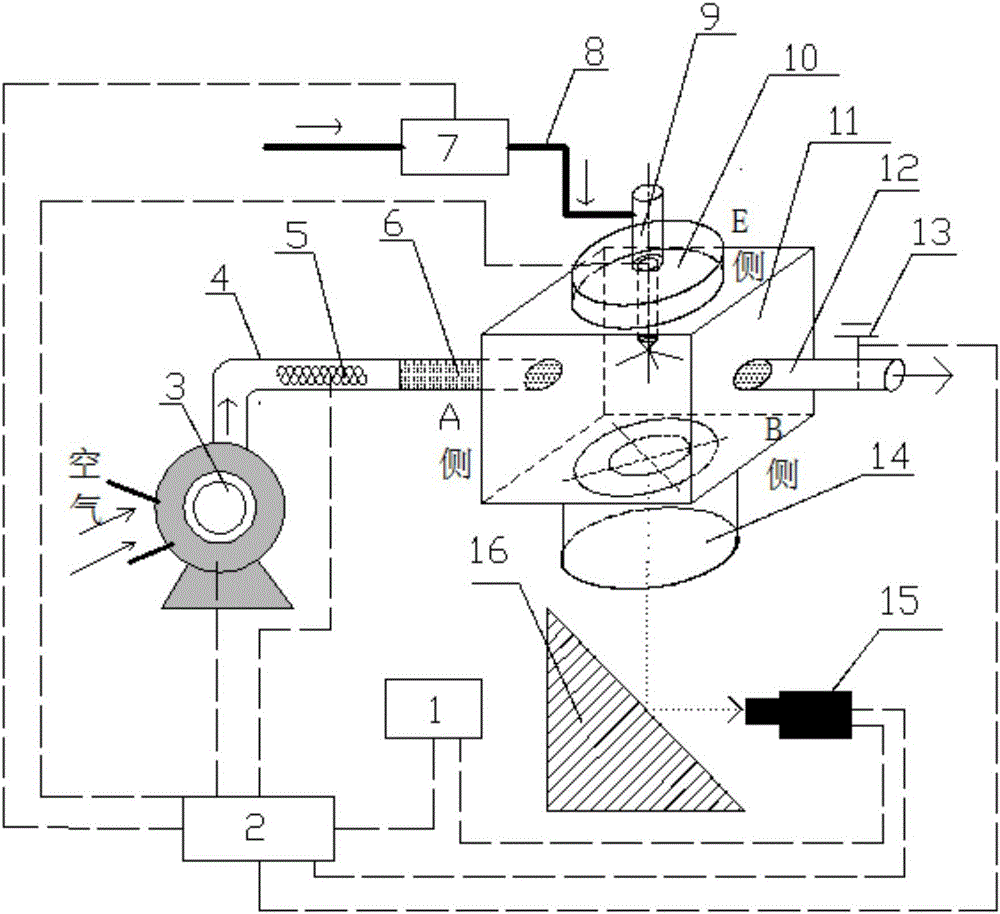

[0136] Such as figure 1 , figure 2 As shown, a device for measuring the uniformity of each nozzle hole of a fuel injector of the present invention includes a high-temperature and high-pressure device body, an oil supply system, a synchronous control system 2, an intake air heating and pressurizing system, a high-speed camera 15, an exhaust cooling system, Computer 1, 45 degree plane mirror 16.

[0137] Such as figure 2 As shown, the intake heating and pressurizing system is composed of an air compressor 3 , an intake pipe 4 , a heating wire 5 , and a porous medium 6 . The air outlet end of the air compressor 3 is fixed together with one end of the intake pipe 4 by welding. Starting from this end, heating wires 5 and porous media 6 are sequentially arranged along the axis of the intake pipe 4 . The heating wire 5 is closer to the air compressor 3 and is located at the upstream section of the incoming air flow. The porous medium 6 is far away from the air compressor 3 and...

Embodiment 3

[0146] In Example 1, the fuel is sprayed from each injection hole and atomized instantly, and the atomized fuel is ignited by the high-temperature and high-pressure ambient gas, which is simulating the working mode of compression ignition of a diesel engine. The present invention is also applicable to the consistency and durability detection of each nozzle hole of the fuel injector under the working mode of the gasoline engine, and will be described in detail through Embodiment 3 below.

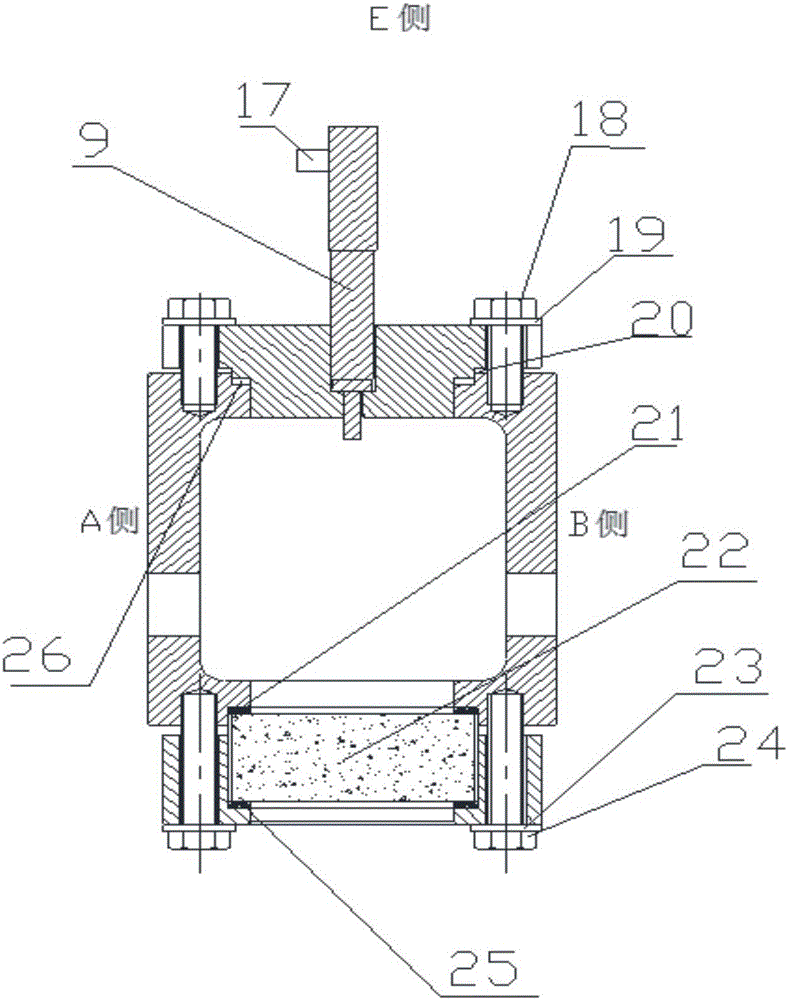

[0147] as attached figure 2 As shown, on the side of the combustion chamber 11E, there are H small threaded through holes, and these threaded through holes take the center of the E side as the center and are evenly distributed on the E side. Wherein, the value of H is equal to the number of nozzle holes of the fuel injector 9. In this embodiment, the value of H is 4, and the value of N is 8. The other assembly and connection relations are the same as in Embodiment 1, and the 4 threaded throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com