Domestic air purifier

An air purifier and household technology, which is applied in household appliances, household heating, household heating, etc., can solve the problems of water turbidity, affecting the effect of air purification, and the effect of not being able to improve the effect of air purification, so as to enhance the purification effect , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

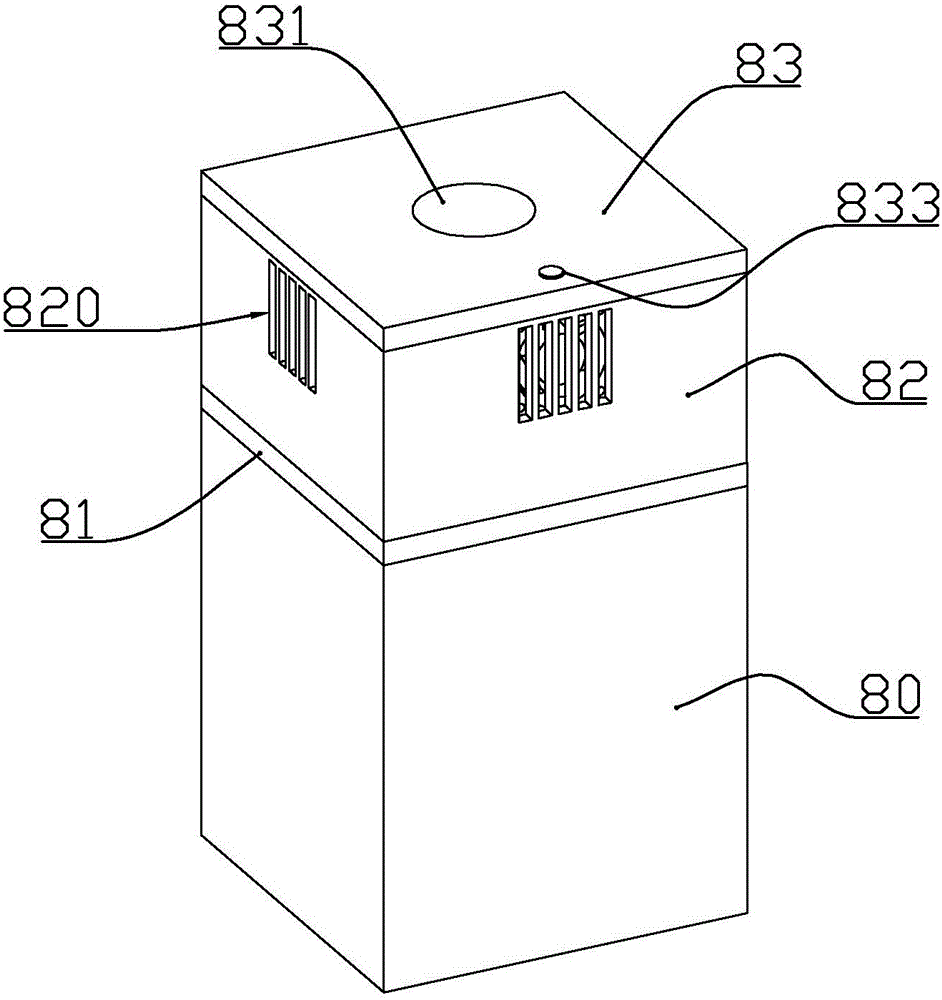

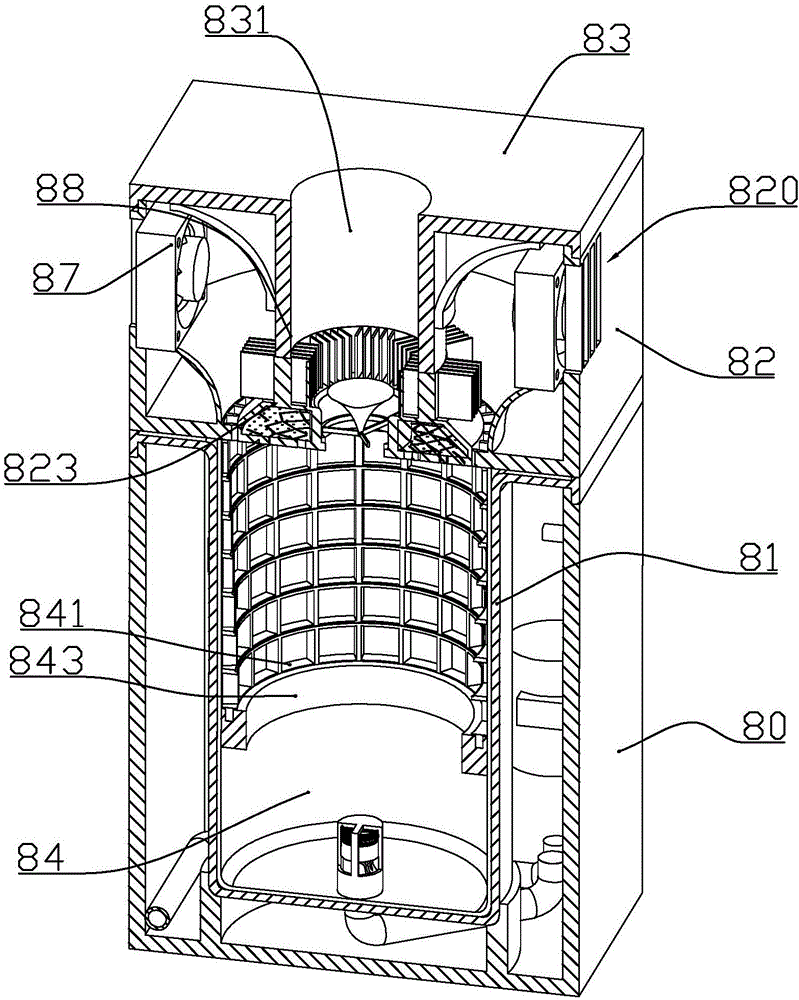

[0080] according to Figure 1 to Figure 9 As shown, the present embodiment is a household air cleaner, which includes an outer casing 80 in the shape of a square tank, and an inner casing 81 that is loaded into the outer casing from top to bottom.

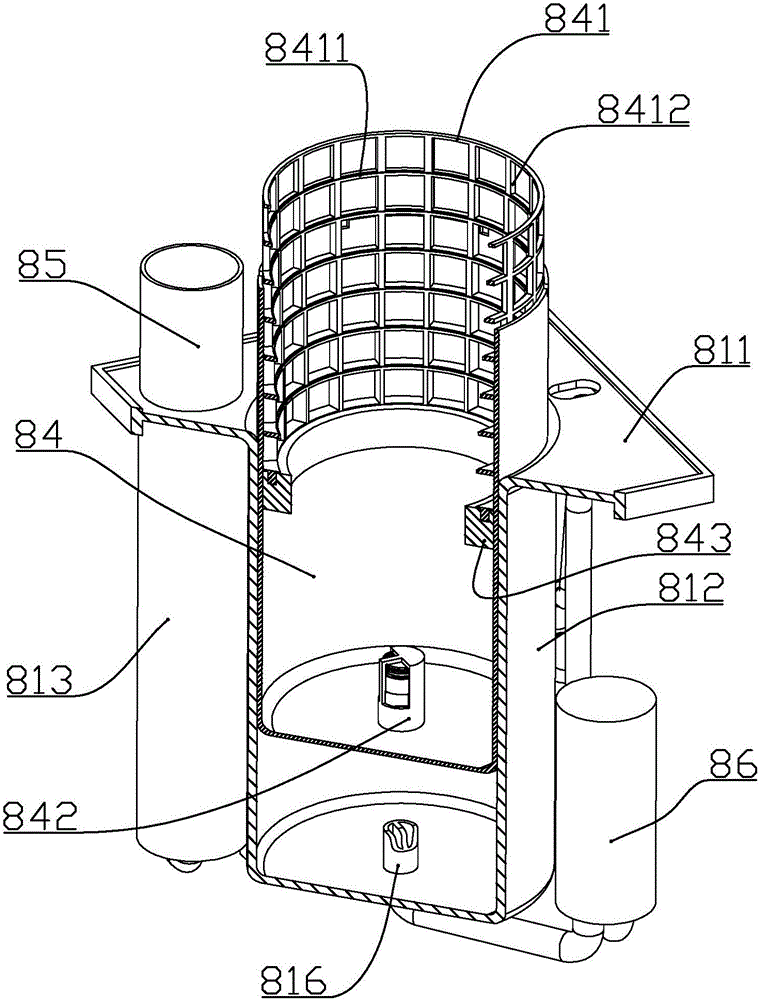

[0081] The inner casing includes a square upper connecting plate 811 that is matched with the upper opening of the outer casing, and a water storage bucket installation groove 812 and a waste water bucket installation groove 813 integrally connected to the upper connection plate; the water storage bucket installation groove is located at At the central position of the upper connecting plate, the installation groove of the waste water bucket is located near a vertex of the upper connecting plate.

[0082] A water storage bucket 84 is installed in the installation groove of the water storage bucket, and a waste water bucket 85 is installed in the installation groove of the waste water bucket; In the middle of the bottom of the water...

Embodiment 2

[0098] This embodiment also makes the following improvements on the basis of embodiment 1: Figure 10 to Figure 17 As shown, the filter P includes a cylinder body 2 and a cover body 1 connected by threads, and a ceramic filter element assembly 3 installed in the space between the cylinder body 2 and the cover body 1 .

[0099] Both sides of the cover body are respectively formed with a waste water outlet interface 11 and a pure water outlet interface 12; a pure water outlet connector 14 is integrally formed in the middle of the inner bottom of the cover body, and the pure water outlet connector 14 is connected with the pure water outlet The interface 12 is connected; the inner bottom of the cover is formed with a waste water outlet 111 connected with the waste water outlet 11 , and a sealing ring 13 is provided around the inner bottom of the cover.

[0100] The ceramic filter element assembly 3 includes a circular tube-shaped ceramic filter element 31 and a first sealing head ...

Embodiment 3

[0133] In this embodiment, on the basis of Embodiment 2, the raw material components of the ceramic filter element include: 80% diatomite, 6% calcium carbonate, 4% kaolin, and 10% activated carbon. The above raw materials are respectively pulverized to Mix after 160-180 mesh, add water to make mud after mixing evenly, use gypsum mold to make mud billet, and sinter to form a finished product. The ceramic filter element is in the shape of a circular tube, the thickness of the ceramic filter element is 5-15 mm, and the pore diameter of the micropores on the ceramic filter element is 0.4-0.8 μm.

[0134] Since the filter is only used to filter out particulate impurities in the water, the filter requirements for drinking water are much lower than that of drinking water, so the ceramic filter element has a larger pore size than the ceramic filter element of the drinking water filter, and the filtration flow rate is larger. The load of the water pump saves energy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com