Wide-channel plate heat exchanger

A plate heat exchanger, wide channel technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of more serious heat conduction effect, low conduction efficiency, troublesome maintenance and disassembly, etc. Achieve the effects of preventing deposition, speeding up efficiency, and convenient cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

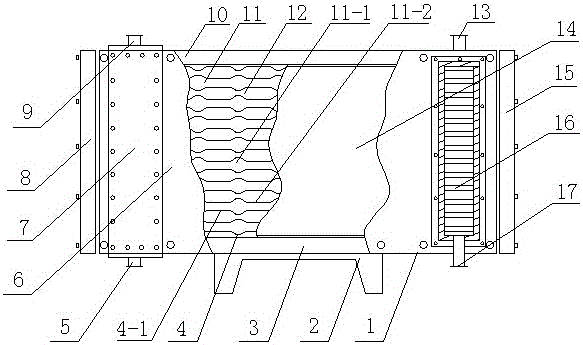

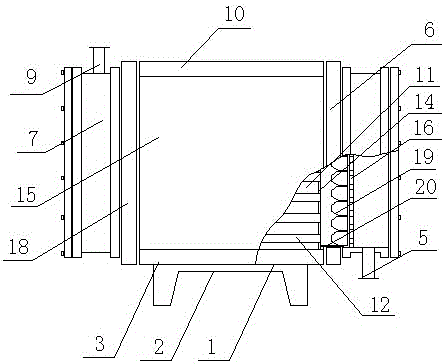

[0028] Such as figure 1 , figure 2 As shown, the wide-channel plate heat exchanger of the present invention includes a support 2, a shell 1, a heat exchange core 4, heat exchange medium inlets and outlets 5, 9, and heat exchange medium inlets and outlets 13, 17. The heat exchange medium inlet and outlet 5 , 9 and the heat exchange medium inlet and outlet 13 , 17 are located on the shell 1 and communicate with the heat exchange core 4 . , the shell 1 is a combined structure, consisting of four side plates 10, 3, 6, 18 connected by bolts, and end covers 8, 15 are arranged at both ends, thus forming a fully disassembled heat exchanger shell Body 1, very convenient for installation and maintenance. The heat exchange medium inlets and outlets 5, 9 and the heat exchange medium inlets and outlets 13, 17 are respectively located at the two ends of the front and rear side plates 6, 18. The heat exchanging core 4 is composed of several heat exchanging plates 4-1 and the partitions ...

Embodiment 2

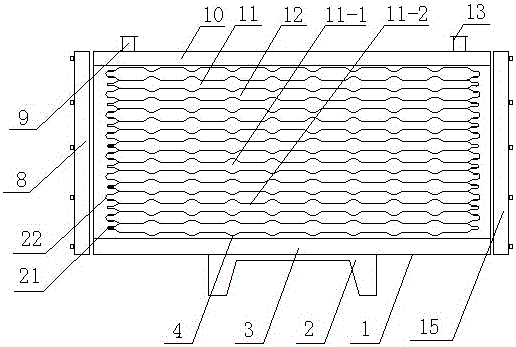

[0030] see image 3 , as a further improvement, in this embodiment, the ends of the heat exchange medium circulation channel 11 and the heat exchange medium circulation channel 12 are welded and sealed with U-shaped wrapping strips 21 and 22, and the heat exchange plate 4-1 The internal welding seam is changed to the external welding seam, and laser welding can be used first and then argon arc welding for two-layer welding, which can effectively increase the joint fastness between the heat exchange plates 14 and reliably avoid tear damage phenomenon.

Embodiment 3

[0032] see figure 2 , as a further improvement, in this embodiment, the heat exchange medium inlet and outlet 5, 9 and the heat exchange medium inlet and outlet 13, 17 are respectively provided with a buffer distribution box 7, and the buffer distribution box 7 is respectively connected to the The front and rear side plates 6, 7 are detachably connected, and the outer side is connected with a sealing cover plate, and the inlet and outlet with heat exchange medium inlet and outlet 5, 9 and heat exchange medium inlet and outlet 13, 17 are arranged on the peripheral side. Material short tube. The partition plate 14 is welded and connected with the inlet and outlet drainage tubes 20 corresponding to the buffer distribution box, the inner wall of the drainage tube 20 and the heat exchange medium inlet and outlet 5, 9 and the heat exchange medium inlet and outlet 13, 17 and its inner wall. A polymer wear-resistant coating is provided on the joint to prolong the service life of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com