Device of utilizing planar mirror set to determine qualification of shelf crossbeams

A technology for shelf beams and plane mirrors, which is applied in the direction of optical devices, measuring devices, and optical testing flaws/defects, etc., which can solve the problems of low image definition of mounting holes, difficult image processing, and easy mutual influence, etc., to improve The effect of detection efficiency and detection quality, improvement of production efficiency and detection efficiency, and convenient detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

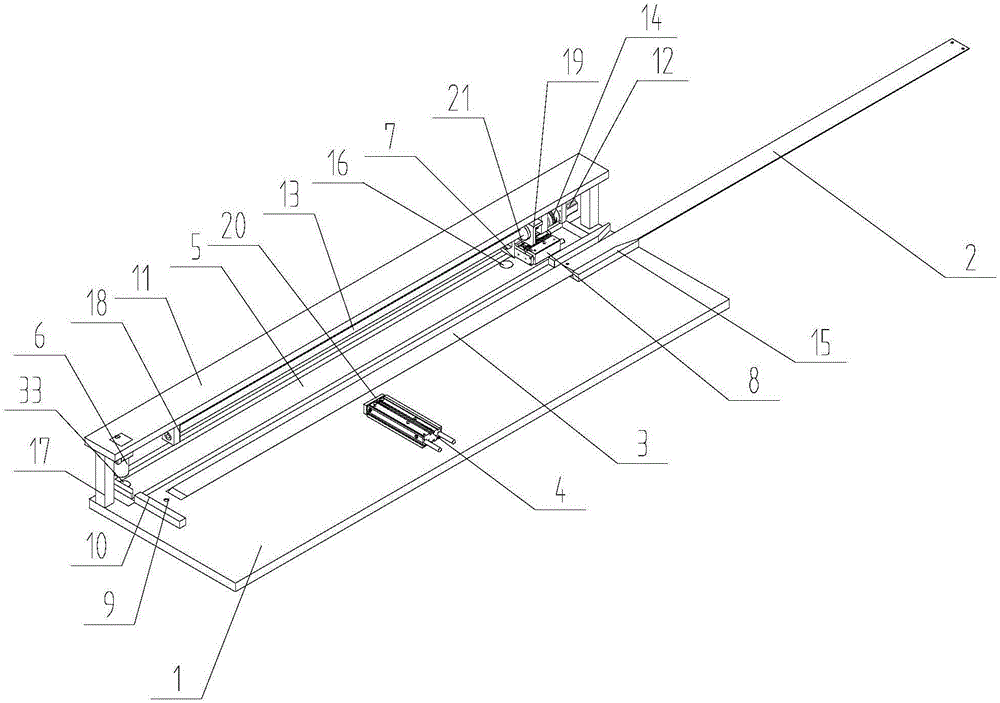

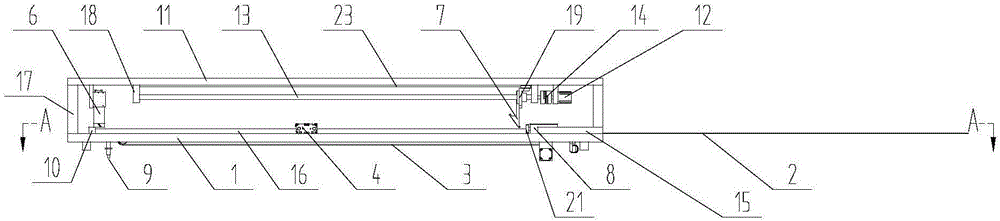

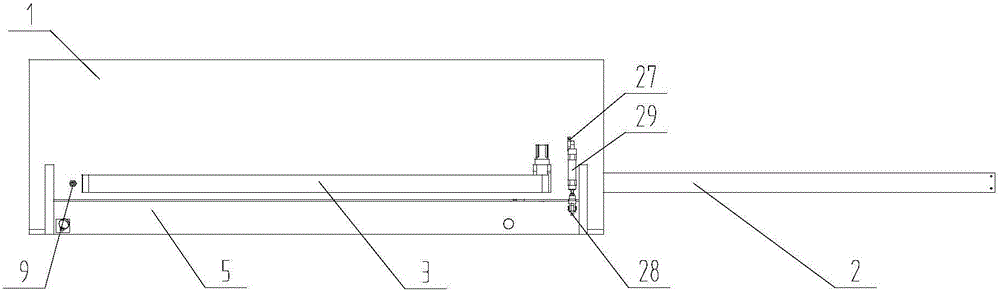

[0044] Below in conjunction with accompanying drawing, the present invention is further described:

[0045] refer to Figure 1-10 As shown, a device of the present invention that utilizes a plane mirror group to judge whether a shelf beam is qualified or not includes a base 1, a conveyor belt 3, a proximity switch 9, a block 10, a push cylinder 4, a measuring bracket 5, a gantry 11, and an image capture module, lead screw drive module, compression cylinder 8 and overturn drive module, the conveyor belt 3 is arranged on the base 1, the feed port of the conveyor belt 3 is connected to the discharge port of the pre-cutting process, and the conveyor belt The end of the conveyor belt 3 is provided with a proximity switch 9 and a stopper 10 in turn along the moving direction of the conveyor belt 3. The proximity switch 9 is embedded in the base 1 and is used to detect whether there is a workpiece 2 to be measured on the base 1. The stopper 10 is fixed Above the base 1 and used to l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com