Machine tool transmission chain detection device and detection method

A machine tool transmission and detection device technology, applied in the field of precision machine tools, to achieve the effects of shortening installation time, eliminating measurement errors, and fast accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] A machine tool transmission chain detection device is used to detect the transmission accuracy of the machine tool transmission chain.

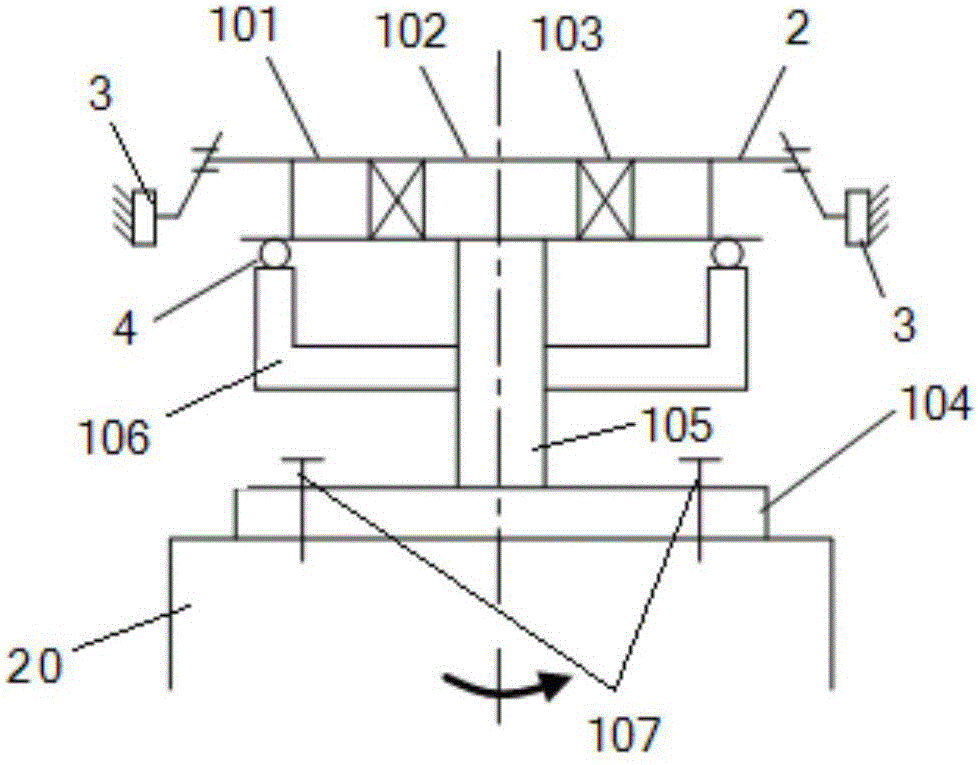

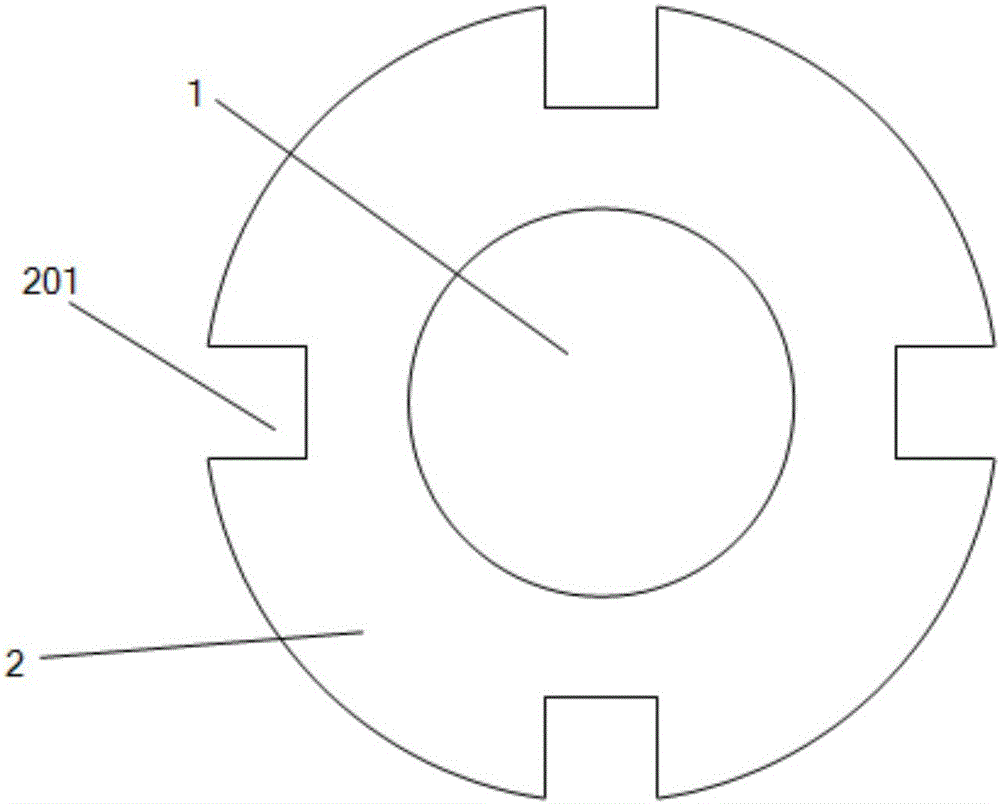

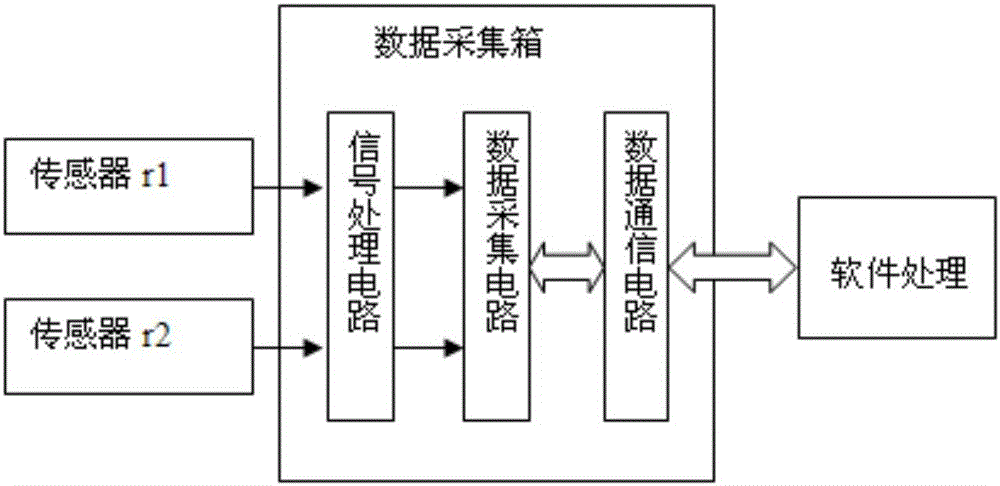

[0027] The detection device includes a tool rod angular displacement sensor, a worktable angular displacement sensor 1 and a rotary transmission precision measuring instrument. The rotary transmission precision measuring instrument detects the transmission error according to the principle of synchronous displacement comparison. The system composition of the measuring instrument is as follows: image 3 As shown, its software processing block diagram is shown in Figure 4 shown. The tool rod angular displacement sensor is installed at the output end of the tool rod of the machine tool, and is used to measure the rotation angle of the tool rod of the machine tool, and the spindle motor of the machine tool drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com