Automatic sorting device and method for textile materials

A technology for automatic sorting of textile materials, applied in the field of textile equipment, can solve the problems of unclean selection of defective products, reduce workshops, and high costs, and achieve the effects of automatic sorting, reduced production costs, and reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

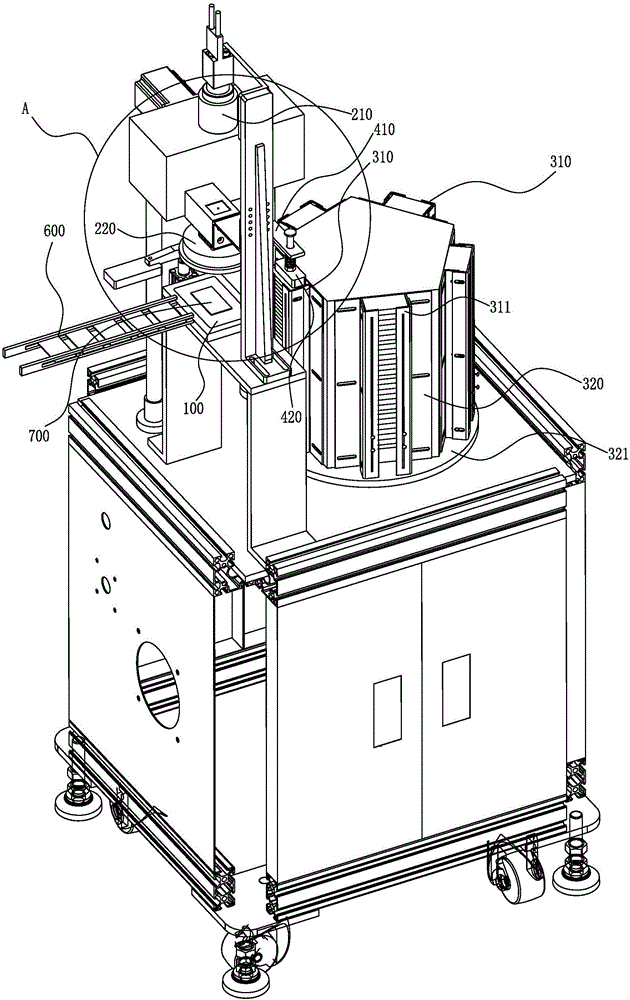

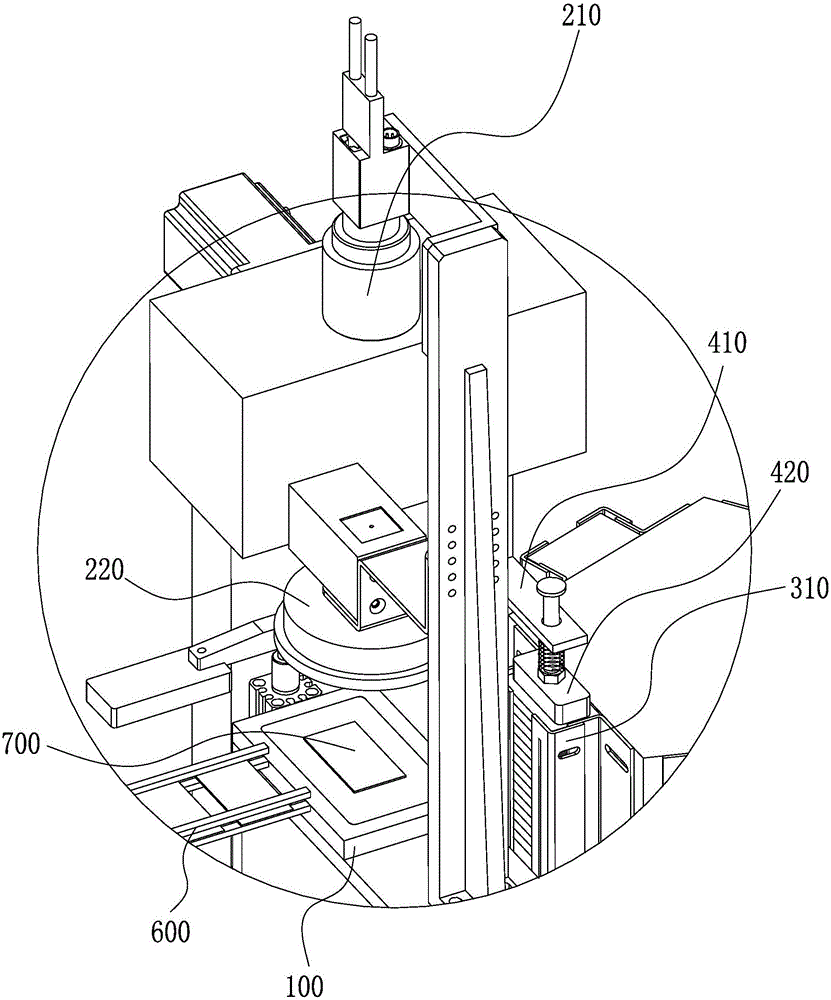

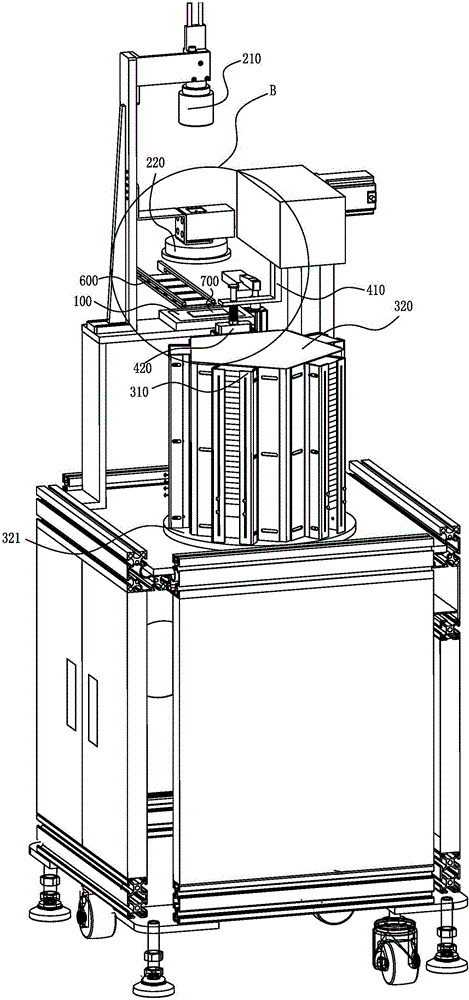

[0041] A kind of textile material automatic sorting equipment, such as Figure 1-4 As shown, it includes: a detection platform 100, an image detection mechanism, a receiving mechanism, a transfer mechanism and a control mechanism.

[0042] The detection platform 100 is used to place the textile material 700 to be sorted.

[0043]In actual production, the detection platform 100 can usually be connected with the feeding paddle 600 of the folding and shearing machine used for cutting and / or folding textile materials. The automatic sorting equipment is used in conjunction with the folding and shearing machine, and the synchronous operation with the folding and shearing machine can further improve the degree of production automation. However, the automatic sorting equipment can also be used without cooperating with the folding and shearing machine, and can also complete the automatic sorting work.

[0044] The image detection mechanism includes an image collector 210 and a data a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com