Cleaning drying device for refrigerating parts

A technology of drying device and accessories, which is applied in the directions of drying gas arrangement, cleaning method using liquid, cleaning method using gas flow, etc. , Improve cleaning efficiency, reasonable and compact structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

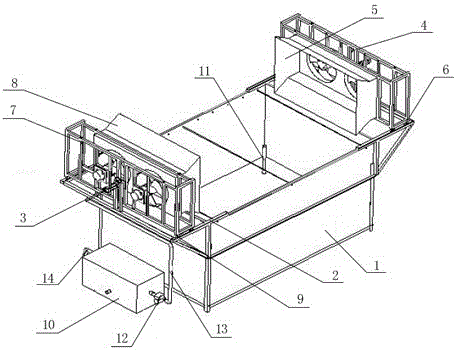

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, a cleaning and drying device for refrigeration accessories of the present invention includes a cleaning tank, a cold air device, an electric heating device, and an oil-water separator. 1. The chute 2, the cylinder 3, the chute 2 is set along the long axis direction of the upper end of the tank body 1, the two ends of the tank body 1 are fixed with the cylinder 3, the cylinder 3 is arranged perpendicular to the short axis direction of the tank body 1, the cooling air device and The electric heating device is arranged between the two cylinders 3, and the cold air device includes a first support 4 and a cooling fan 5 installed on the first support 4. The piston rod is connected, and a number of first rollers 6 are installed at the lower end and arranged in the chute 2; the electric heating device includes a second support 7 and a hot air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com