Crankshaft grinding machine servo center frame

A technology of crankshaft grinding machine and center frame, which is applied in the direction of grinding machines, grinding workpiece supports, and machine tools designed for grinding the rotating surface of workpieces, etc. It can solve the problem that the center frame cannot achieve the grinding accuracy of the crankshaft and the journal, and the deformation of the crankshaft, etc. problem, achieve the effect of preventing micro-deformation, protecting the crankshaft and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

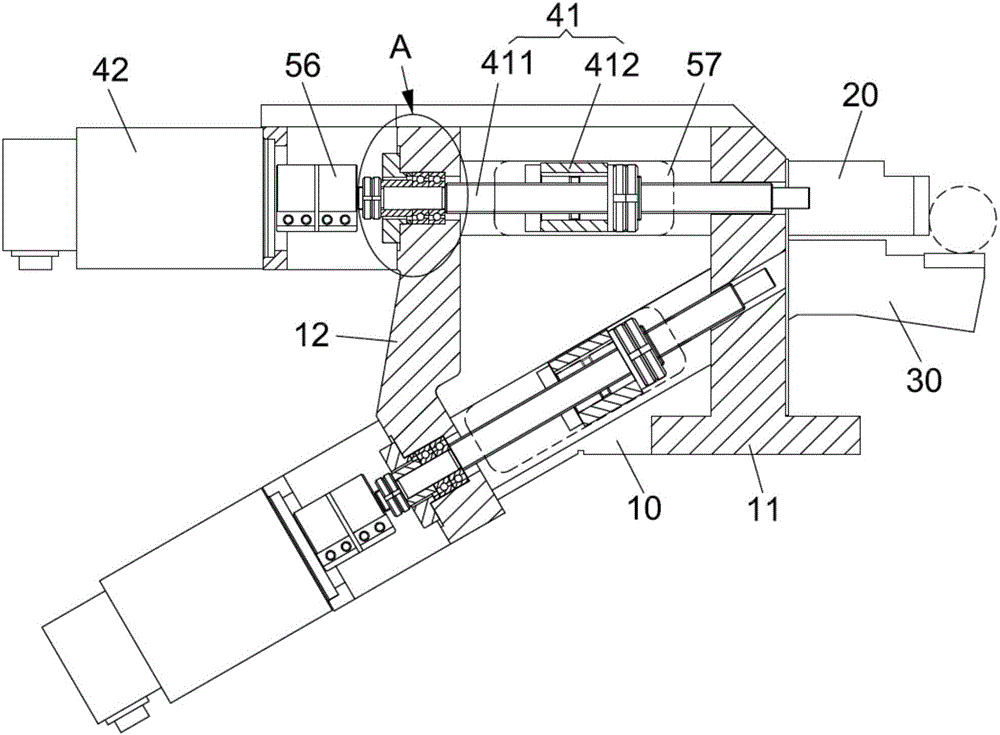

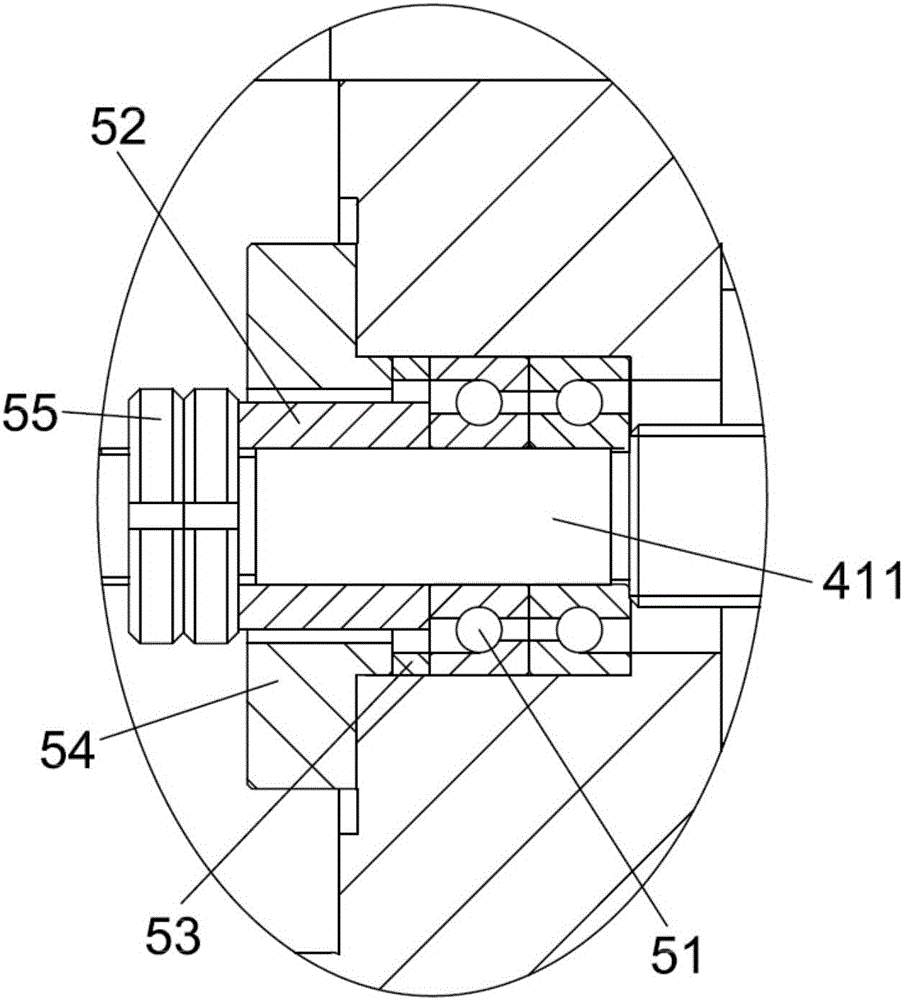

[0021] refer to Figure 1 to Figure 5 , The present invention provides a crankshaft grinder servo steady rest, including a bracket 10, a positioning rod 1 20, a positioning rod 2 30 and 2 sets of drive assemblies, and the positioning rod 2 30 includes an inclined driving section 31. The drive assembly includes a screw transmission mechanism 41 and a motor 42 that drives the screw transmission mechanism 41. The screw transmission mechanism 41 adopts a ball screw nut pair, which has high transmission efficiency and long life, and can realize micro-quantity and high-speed feeding; 42 adopts the servo motor 42 with self-locking function, and the servo motor 42 can correct and compensate the deformation of the crankshaft in real time;

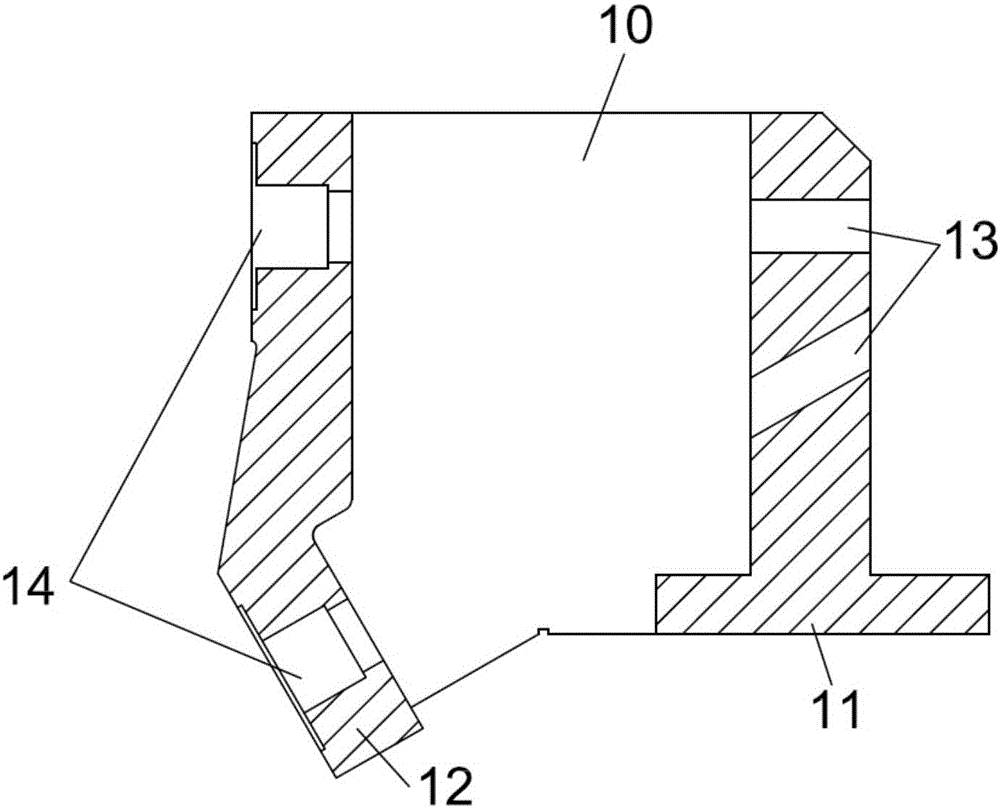

[0022] refer to figure 2 and image 3 The bracket 10 includes a support portion 11 and a positioning portion 12, the support portion 11 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com